Mechanical grabbing hand for scaffold

A scaffolding and grasping hand technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of personnel damage to parts, unable to maintain, loss, etc., to reduce losses, prevent damage or personnel damage, and maintain firm clamping sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

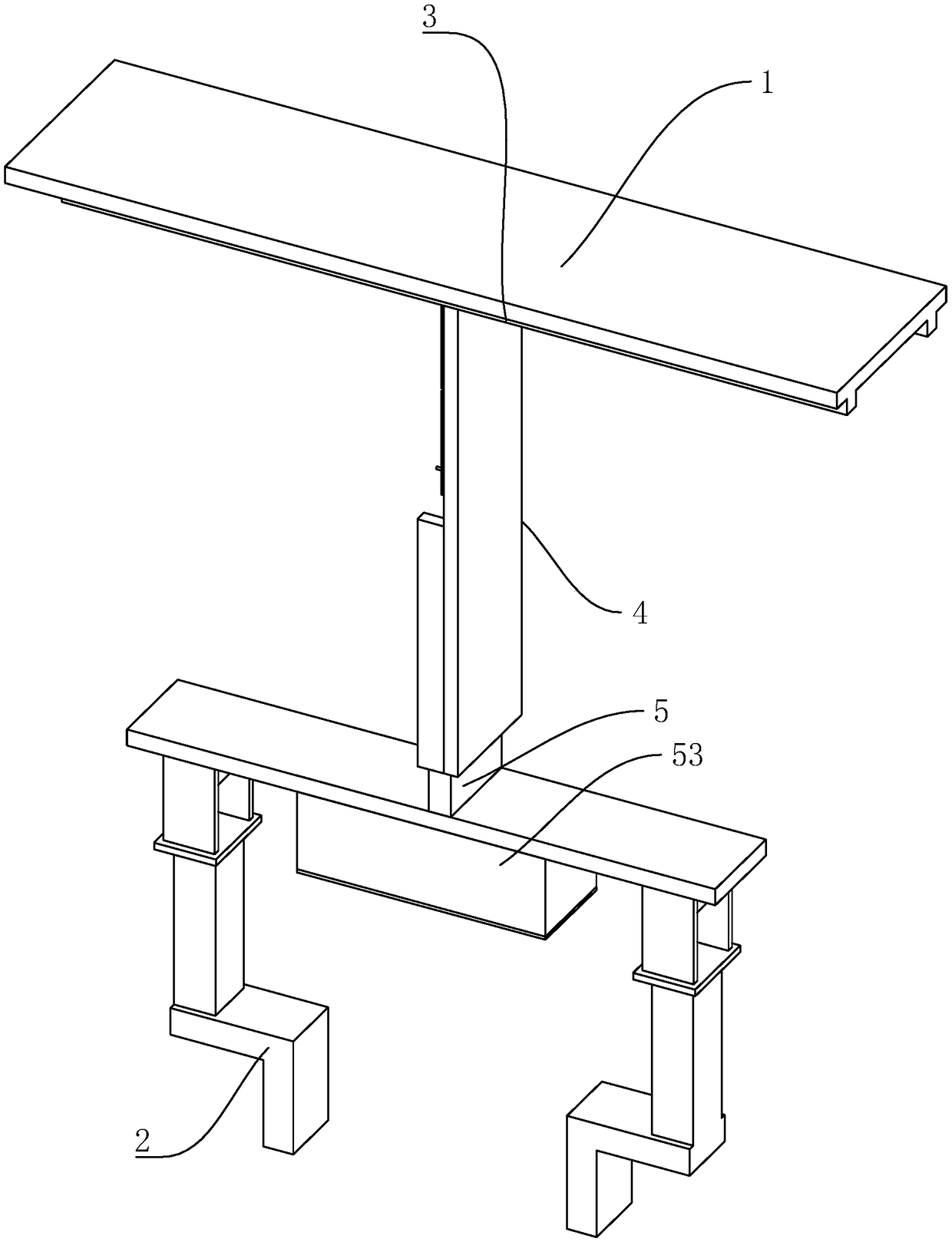

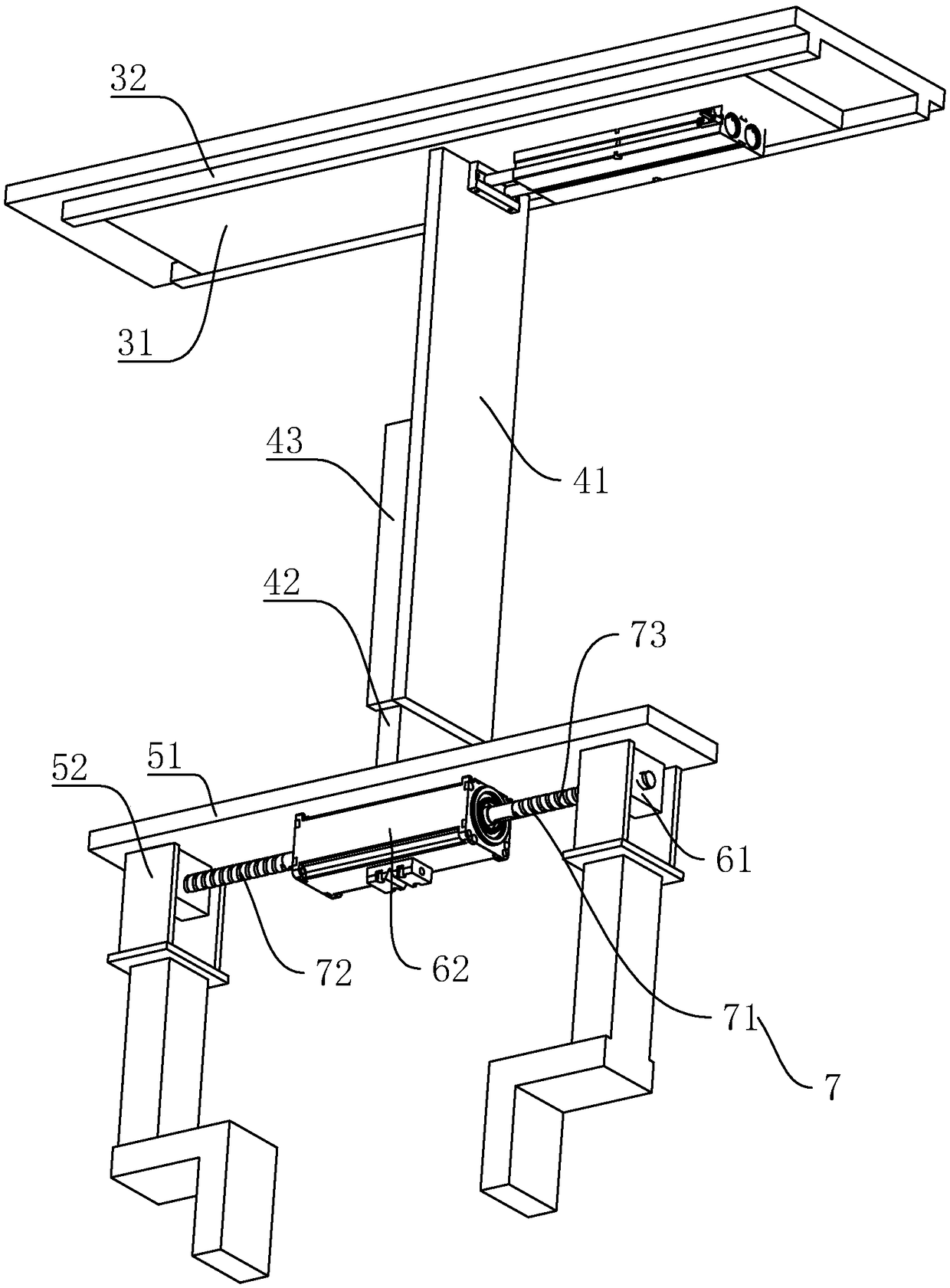

[0037] Embodiment 1, a kind of mechanical grasping hand for scaffolding, such as figure 1 and figure 2 As shown, it includes the mounting plate 1 and the jaw 2. The X-axis action mechanism 3, the Y-axis action mechanism 4, and the Z-axis action mechanism 5 are connected in sequence between the installation plate 1 and the jaw 2. The X-axis action mechanism 3 slides Connected to the mounting plate 1, it can drive the jaws 2 to move in the X-axis direction; the Y-axis action mechanism 4 is slidably connected to the X-axis action mechanism 3, and can drive the jaws 2 to move in the Y-axis direction; the Z-axis action mechanism 5. It is slidingly connected to the Y-axis action mechanism 4, and is used to drive the jaw 2 to move in the Z-axis direction.

[0038] Such as figure 1 and figure 2 As shown, the Z-axis action mechanism 5 is also provided with a driving mechanism 6, which is connected with the jaws 2 and is used to drive the jaws 2 to complete the clamping of parts. ...

Embodiment 2

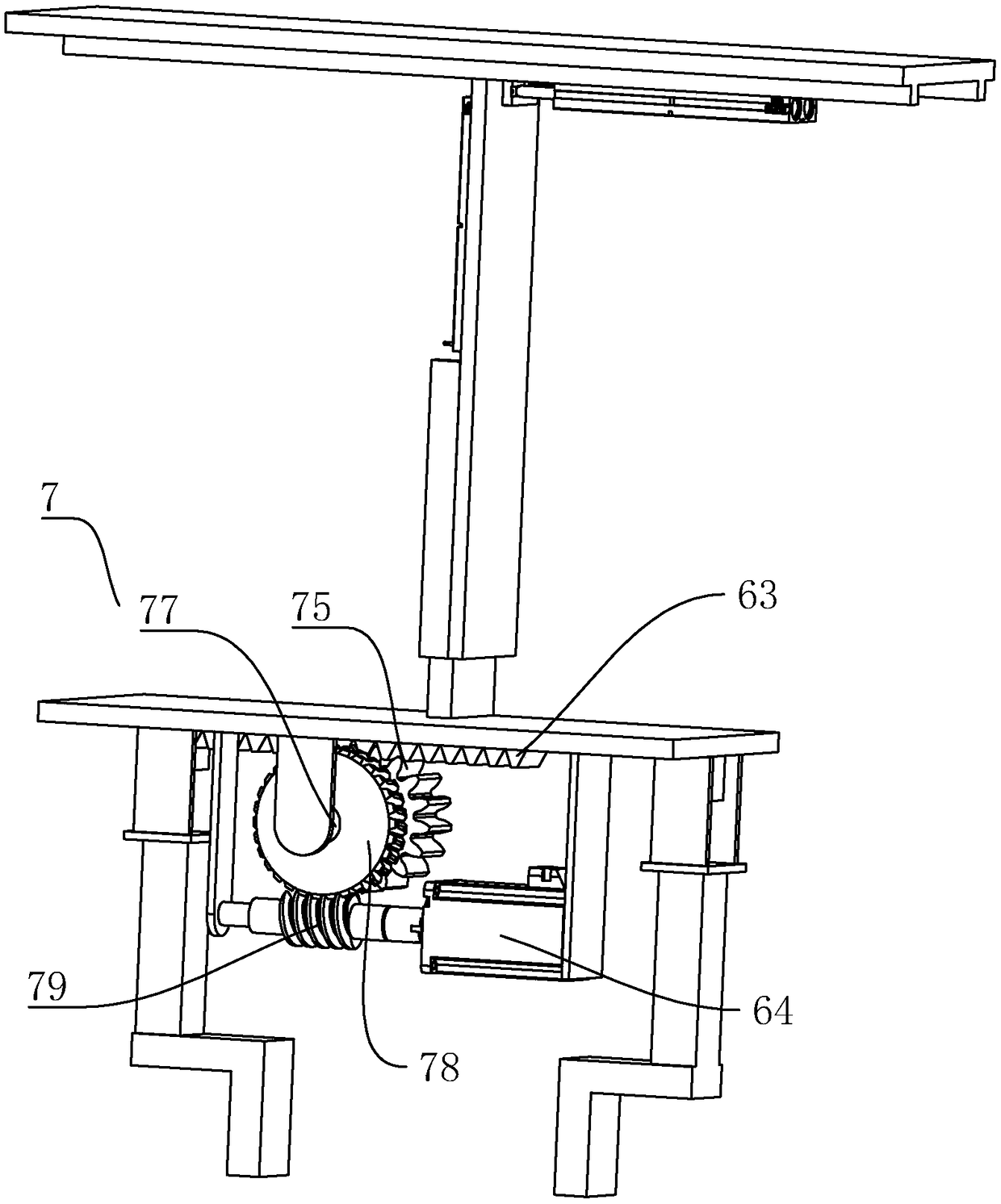

[0043] Embodiment 2, a kind of mechanical grasping hand for scaffolding, such as image 3 As shown, the difference from Embodiment 1 is that the drive mechanism 6 includes two movable racks 63 that are oppositely arranged and slidably connected to the Z-axis action mechanism 5, and the corresponding movable racks 63 are provided on the Z-axis action mechanism 5. The driving gear 75, the movable rack 63 is driven to rotate by the driving gear 75.

[0044] The driving gear 75 is connected to the Z-axis action mechanism 5 through the rotation shaft 77, and the locking mechanism 7 includes a drive worm gear 78 fixed on the rotation shaft 77 and a drive worm gear 78 that is rotatably connected to the Z-axis action mechanism and meshed with the drive worm gear 78. The driving worm 79, the driving mechanism 6 also includes a driving motor 64 for driving the driving worm 79 to rotate.

[0045] The driving motor 64 drives the driving worm 79 to rotate, thereby driving the worm gear 78...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com