A multi-directional intelligent heat riveting seat structure

A technology of welding seat and connecting structure, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., to achieve the effects of improving quality, adjusting displacement conveniently and effectively, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

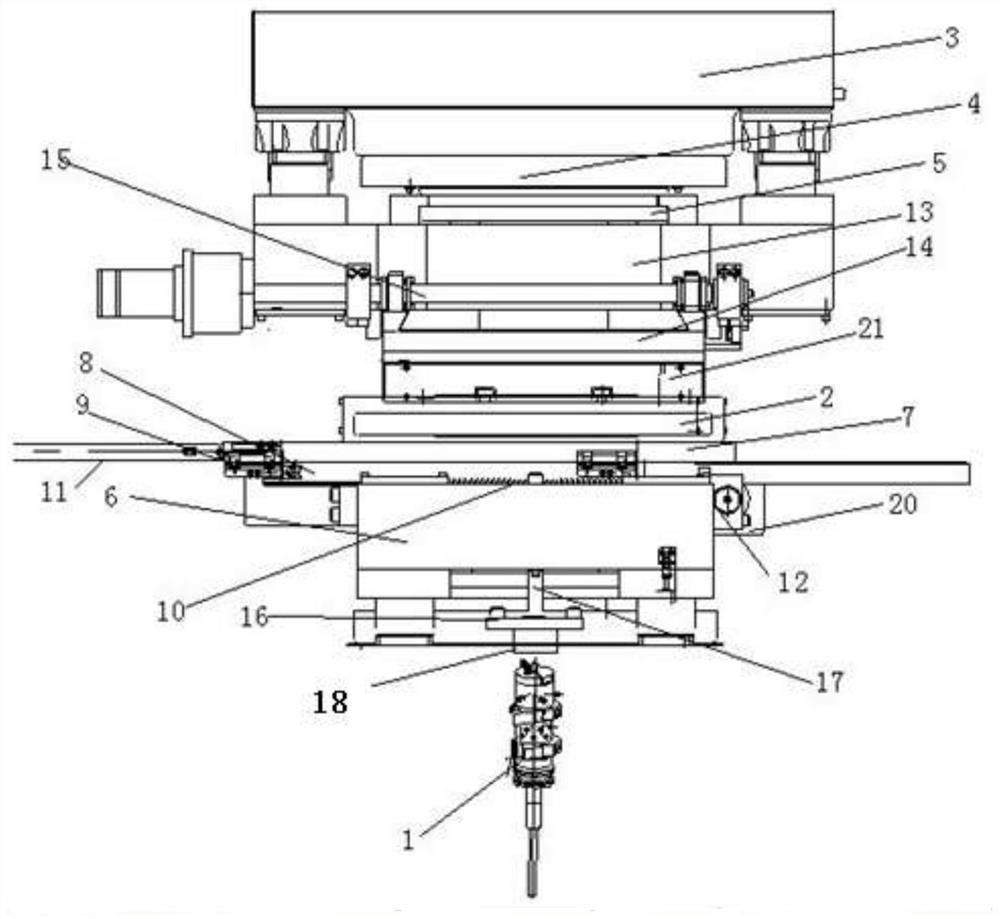

[0011] Example 1, such as figure 1 As shown, a multi-directional intelligent thermal rivet welding seat structure, the multi-directional intelligent thermal rivet welding seat structure includes an upper positioning adjustment structure, a connection ultrasonic welding head structure 1, a lower connection structure and an upper positioning The multi-directional position adjustment seat on the upper part of the adjustment structure, the upper positioning adjustment structure includes the upper connection block 2, the upper mobile platform 21 arranged on the upper part of the upper connection block, the sliding adjustment structure arranged on the lower part of the upper mobile platform, and the upper mobile platform. Move the inner connection plate at the rear of the adjustment structure, the multi-directional adjustment seat includes the main connection platform 3, the shaft sleeve 4 arranged at the center position of the lower part of the main connection platform 3, the multi-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com