Anti-freezing liquid tank, anti-freezing liquid tank system and anti-freezing method

An anti-coagulation and liquid tank technology, used in the field of anti-coagulation, anti-coagulation liquid tanks, and anti-coagulation liquid tank systems, can solve problems such as user inconvenience, affecting cleaning or coating quality, and achieve the effect of preventing liquid coagulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

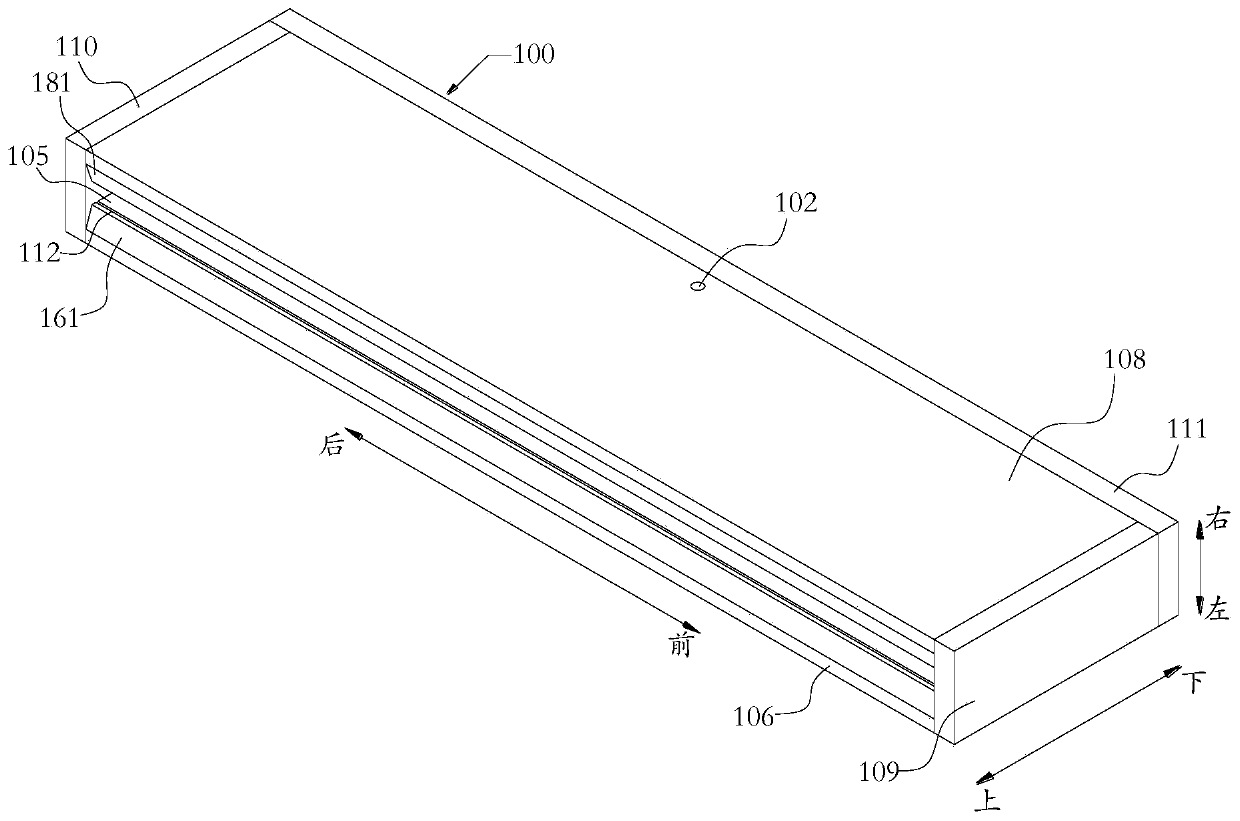

[0052] Such as Figure 1-Figure 8 As shown, in the anti-freezing liquid tank of this embodiment, the bottom of the liquid tank 100 is provided with a liquid outlet 101, and the position of the side wall of the liquid tank 100 is provided with a liquid inlet 102; 100 is formed with a liquid inlet chamber 103, a liquid storage chamber 114 and a liquid outlet chamber 104, the upper end of the liquid storage chamber 114 is open to communicate with the outside world, the lower end of the liquid storage chamber 114 communicates with the liquid outlet chamber 104, The lower end of the liquid outlet chamber 104 communicates with the liquid outlet 101 ; the upper end of the liquid inlet chamber 103 communicates with the upper end of the liquid storage chamber 114 , and the lower end of the liquid inlet chamber 103 communicates with the liquid inlet 102 .

[0053] In this embodiment, the number of liquid inlets and liquid outlets in the liquid tank 100 can be set according to actual nee...

Embodiment 2

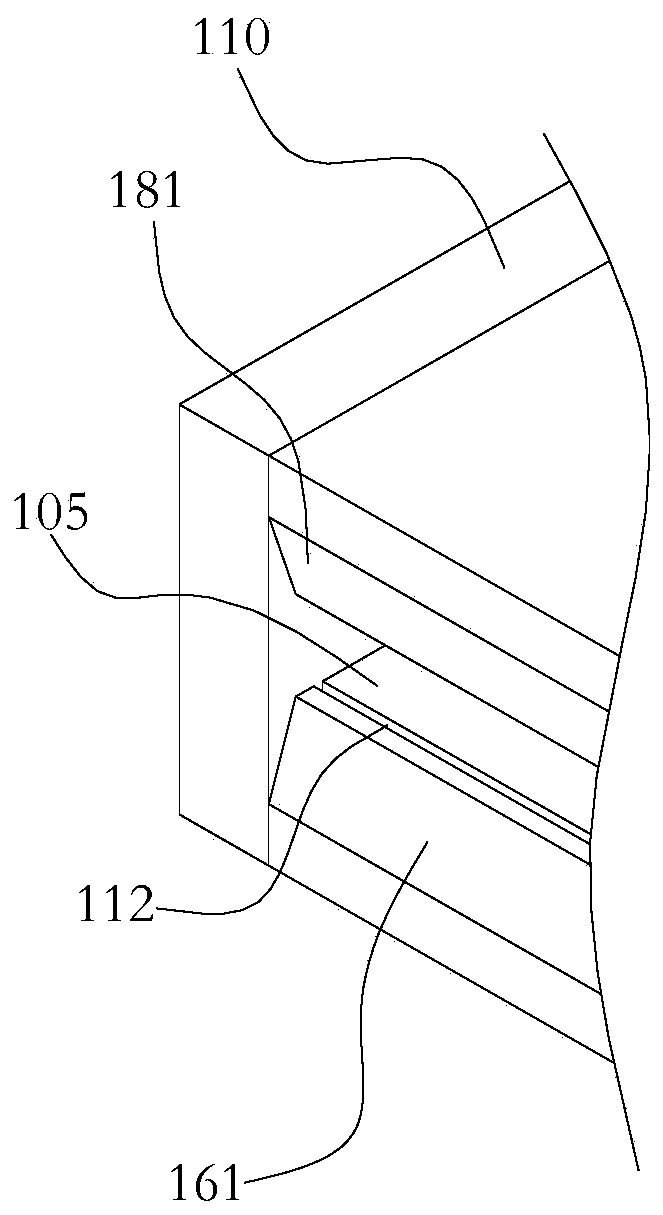

[0056] Such as Figure 1-Figure 8 As shown, in addition to the technical features of Embodiment 1, this embodiment further defines the structures of the liquid inlet chamber 103, the liquid storage chamber 114, and the liquid outlet chamber 104, as follows.

[0057] Such as Figure 4-Figure 8 As shown, the liquid inlet chamber 103 in this embodiment includes an upper liquid inlet buffer chamber 131, several liquid inlet channels 132, and a lower liquid inlet buffer chamber 133 arranged in sequence from top to bottom, and several of the liquid inlet channels 132 are arranged vertically side by side. Arranged and independent of each other; the upper ends of several of the liquid inlet channels 132 are in communication with the upper liquid inlet buffer chamber 131, and the lower ends are in communication with the lower liquid inlet buffer chamber 133; the liquid inlet 101 is connected with the lower liquid inlet The buffer chamber 133 is in communication, and the upper inlet bu...

Embodiment 3

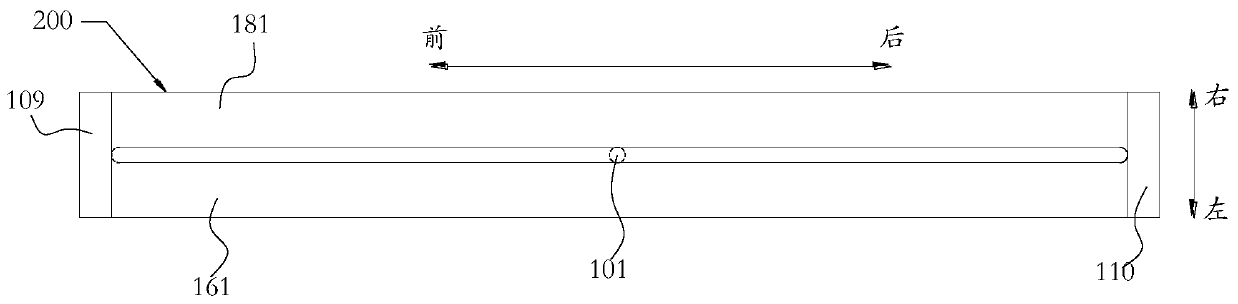

[0067] Such as Figure 9 As shown, an anti-freezing liquid tank system in this embodiment includes the liquid tank 100, the liquid tank circulating pump 200 and the circulating liquid storage barrel 300, and the liquid outlet 101 at the bottom of the liquid tank 100 is connected to the liquid tank through a pipeline. The circulating liquid storage tank 300 is connected and the liquid in the liquid tank 100 is input into the circulating liquid storage tank 300, and the liquid inlet on the side wall of the liquid tank 100 is connected with the circulating liquid storage tank 300 through a pipeline. connected, the liquid tank circulating pump 200 is installed on the pipeline between the liquid inlet 102 and the circulating liquid storage barrel 300 and the liquid in the circulating liquid storing barrel 300 is input into the liquid tank 100 . There is a one-to-two three-way valve at the outlet of the circulating liquid storage pump 200, which divides the liquid into two pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com