Preparation method and application of polymer-metal composite separation membrane

A metal composite and polymer technology, applied in semipermeable membrane separation, chemical instruments and methods, membranes, etc., can solve the problems of large energy consumption and time cost, high material cost and time cost, and limited temperature adjustment range, etc., to achieve Realize large-scale industrial application, realize the effect of sensitivity and no energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

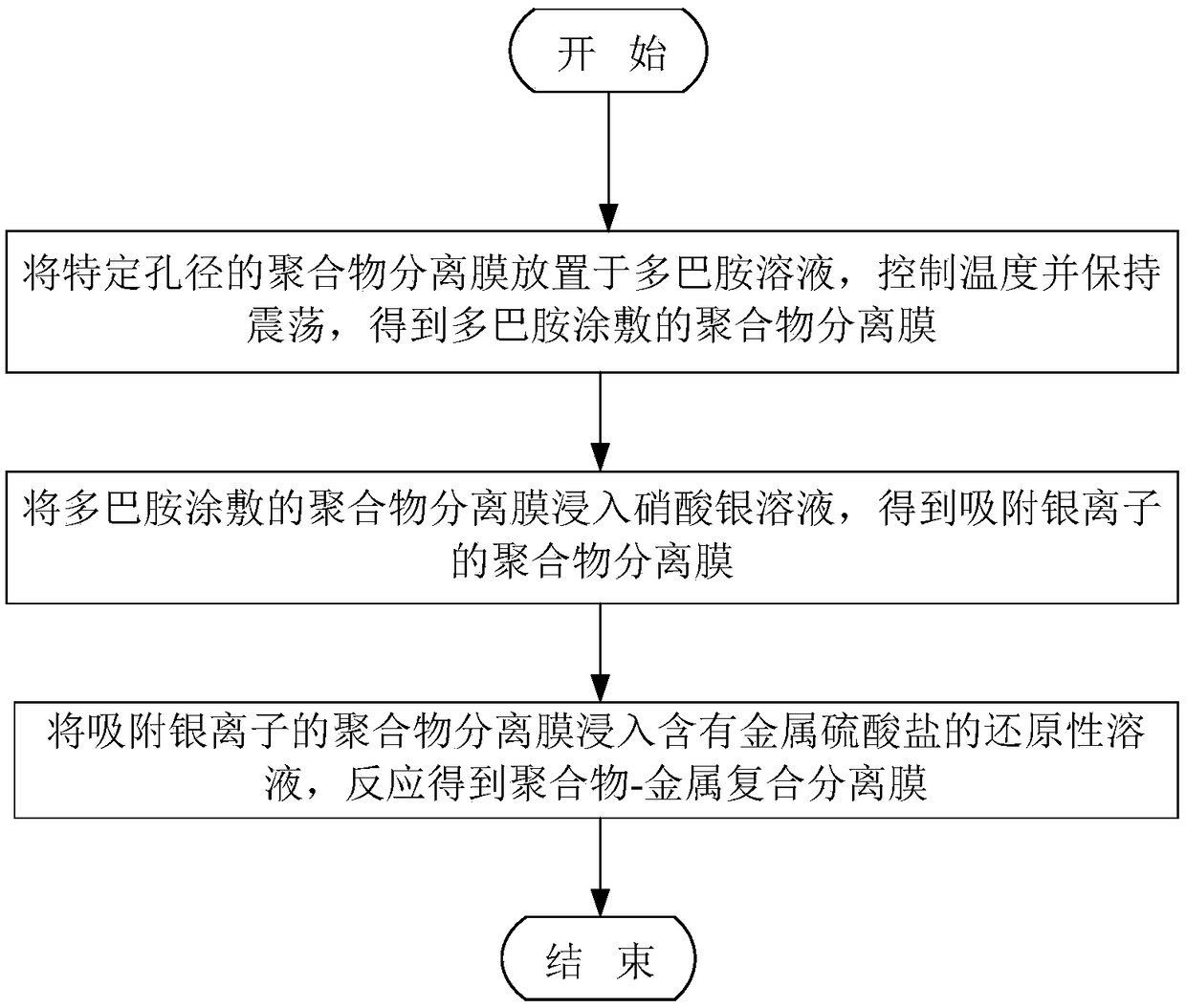

[0030] Example 1 Development of PVDF-Ni (polyvinylidene fluoride-nickel) composite separation membrane

[0031] Add 300 ml of deionized water to a clean beaker, then add 0.06 mol of dopamine to the deionized water, ultrasonicate and stir for 30 minutes, then put a clean polyvinylidene fluoride (PVDF) membrane into the beaker. Then, put it into a shaking incubator and shake it at a constant temperature for 24 hours, so as to obtain a dopamine-coated PVDF membrane. The function of dopamine is to adsorb enough silver ions in the next experiment.

[0032] Add 0.16987 g of silver nitrate into a beaker containing 100 ml of deionized water, and stir ultrasonically for 10 minutes to obtain a silver ion solution. The PVDF membrane coated with dopamine in the previous step was immersed in the silver nitrate solution for 5 minutes to ensure that enough silver ions were adsorbed. The membrane was then removed, and the surface of the membrane was rinsed with deionized water to remove exce...

Embodiment 2

[0038] The development of embodiment 2 PP-Cu (polypropylene-copper) composite separation membrane

[0039]Add 500 ml of deionized water to a clean beaker, then add 0.1 mol dopamine to the deionized water, ultrasonicate and stir for 30 minutes, then put a clean polypropylene (PP) membrane into the beaker. Then, put it into a shaking incubator and shake it at a constant temperature for 24 hours, so as to obtain a dopamine-coated PP film. The function of dopamine is to adsorb enough silver ions in the next experiment.

[0040] Add 0.16987 g of silver nitrate into a beaker containing 100 ml of deionized water, and stir ultrasonically for 10 minutes to obtain a silver ion solution. The PP membrane coated with dopamine in the previous step was immersed in the silver nitrate solution for 5 minutes to ensure that enough silver ions were adsorbed. The membrane was then removed, and the surface of the membrane was rinsed with deionized water to remove excess silver ions.

[0041] In a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com