Microlens array imaging system

A technology of microlens array and imaging system, which is applied in the field of imaging system, can solve the problems of information loss, long image processing time, large manpower and time consumption, etc., achieve small amount of calculation for data processing, improve the overall resolution, and avoid mutual interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

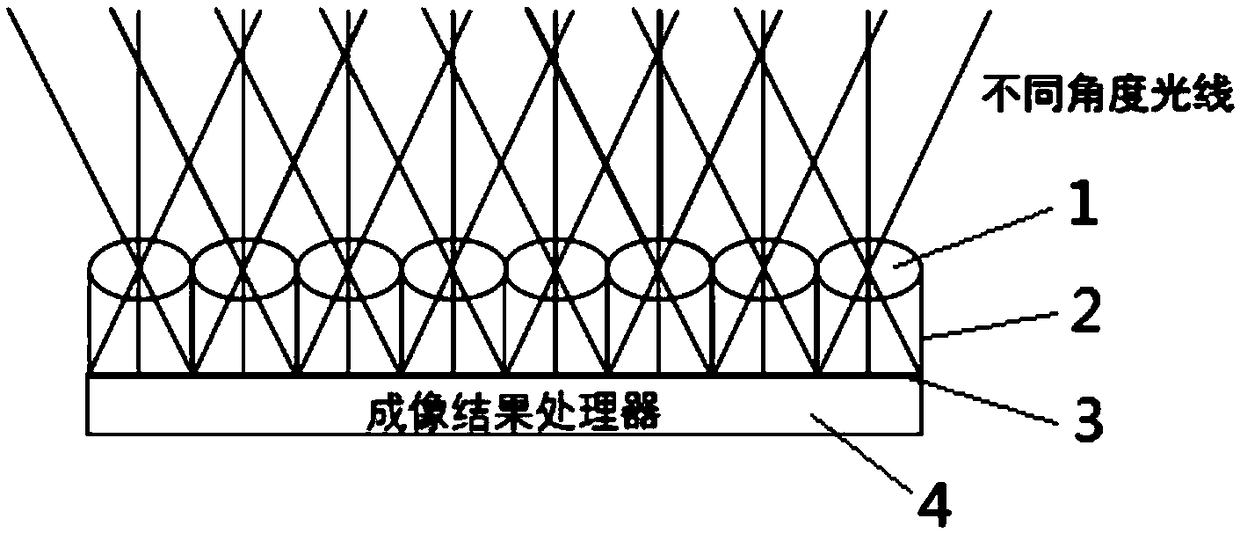

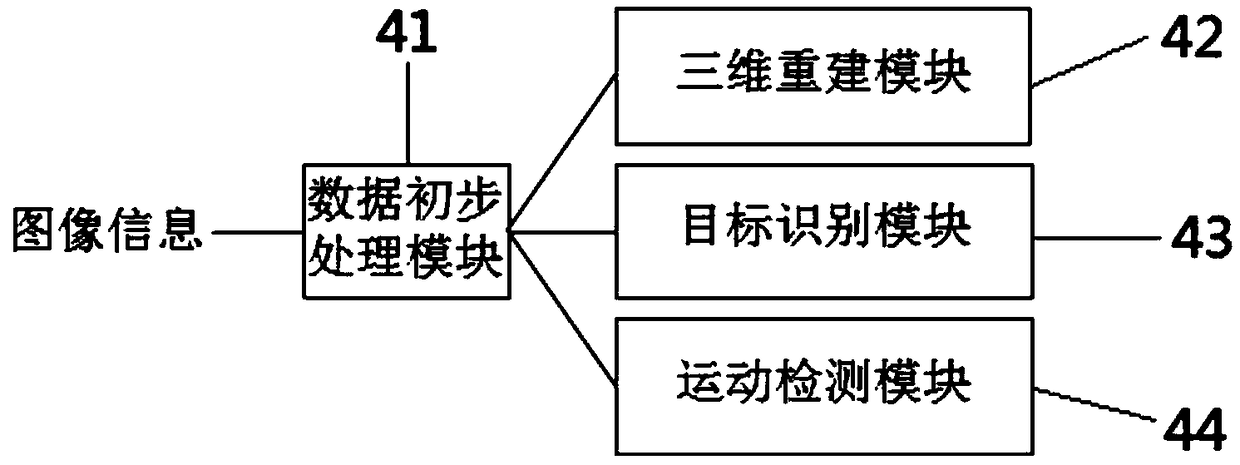

[0020] Such as Figure 1-3 As shown, the present invention, that is, a microlens array imaging system, includes: a microlens array 1, an opaque light-shielding processing structure 2, a photosensitive pixel array 3, and an imaging result processor 4, specifically:

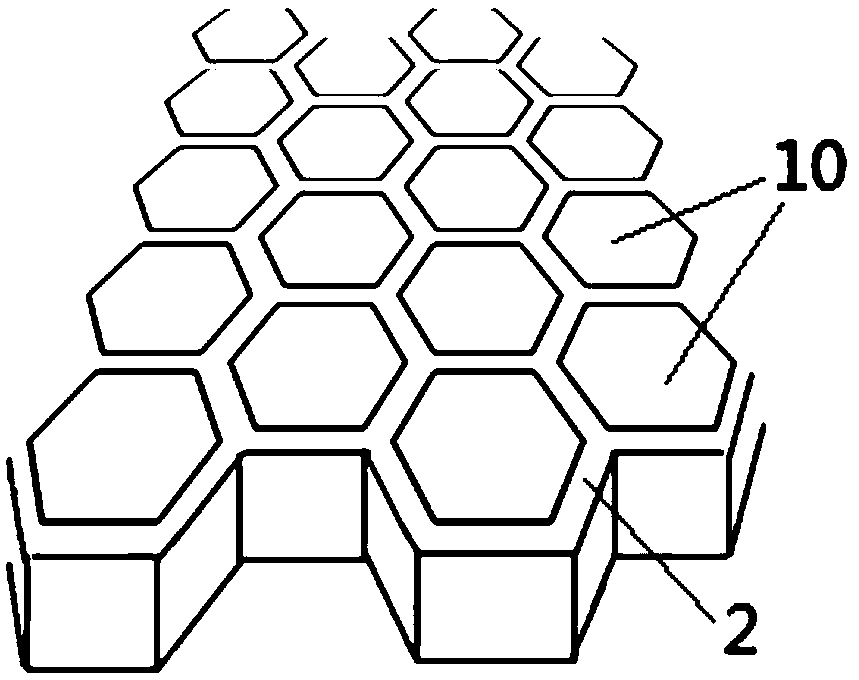

[0021] The microlens array 1 includes a plurality of microlenses 10 arranged adjacent to each other, and each microlens 10 is hexagonal;

[0022] The light-shielding processing structure 2 is arranged between every two adjacent microlenses 10, that is, the periphery of each microlens 10 has a light-shielding processing structure 2, thereby forming a planar or curved honeycomb shape together with a plurality of microlenses 10. grid structure;

[0023] The photosensitive pixel array 3 is used to receive the light transmitted by the microlens array 1, and form an electrical signal that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com