Dynamic vapor-liquid balance measuring device

A measuring device and method of steam technology, applied in the field of experimental equipment, can solve the problems of no heat preservation, air leakage, experimental errors, etc., and achieve the effects of avoiding overheating of the kettle liquid, controllable heat source temperature, and saving test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

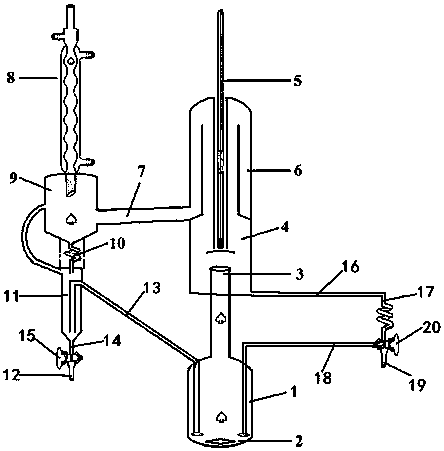

[0028] Such as figure 1 A dynamic vapor-liquid balance measuring device shown includes a balance kettle 1, a vapor-liquid separation bottle 4, a vapor phase condensing device, and several flow tubes.

[0029] The balance tank 1 is provided with a stirring magnet 2 , and the top of the balance tank 1 protrudes outward to form a gas-liquid mixing overflow port 3 . The vapor-liquid mixing overflow port 3 extends into the vapor-liquid separation bottle 4 from the bottom of the vapor-liquid separation bottle 4 . The bottom of the vapor-liquid separation bottle 4 is horizontal, and one side of the bottom is provided with a liquid phase outlet. One top end of the liquid phase flow pipe is connected with the liquid phase outlet, and the other end extends into the equilibrium tank 1 and communicates with the inside of the equilibrium tank 1 . The middle of the vapor-liquid separation bottle 4 is recessed from the top to form a groove, that is, the cross-section of the vapor-liquid se...

Embodiment 2

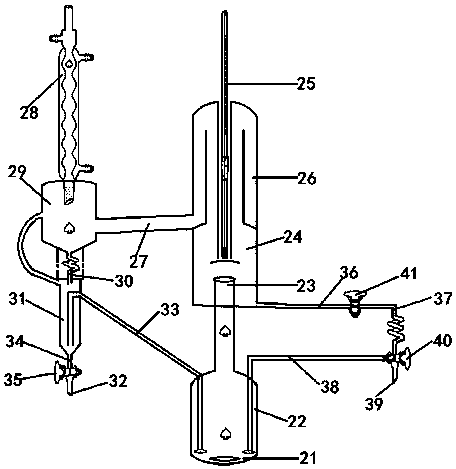

[0036] Such as figure 2 A dynamic vapor-liquid balance measuring device shown includes a balance kettle 21, a vapor-liquid separation bottle 24, a vapor phase condensing device, and several flow tubes.

[0037] A stirring magnet 22 is installed inside the balance tank 21 , and the top of the balance tank 21 protrudes outward to form a vapor-liquid mixing overflow port 23 . The vapor-liquid mixing overflow port 23 extends into the vapor-liquid separation bottle 24 from the bottom of the vapor-liquid separation bottle 24 . The bottom of the vapor-liquid separation bottle 24 is horizontal, and one side of the bottom is provided with a liquid phase outlet. One top end of the liquid phase flow pipe is connected to the liquid phase outlet, and the other top end extends into the balance tank 21 and communicates with the balance tank 21 . The middle part of the vapor-liquid separation bottle 24 is recessed from the top to form a groove, that is, the cross-section of the vapor-liqui...

Embodiment 3

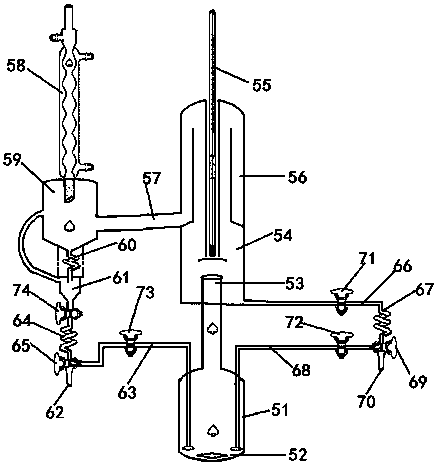

[0045] Such as image 3 A dynamic vapor-liquid balance measuring device shown includes a balance kettle 51, a vapor-liquid separation bottle 54, a vapor phase condensing device, and several flow tubes.

[0046] A stirring magnet 52 is installed inside the balance tank 51 , and the top of the balance tank 51 protrudes outward to form a vapor-liquid mixing overflow port 53 . The vapor-liquid mixing overflow port 53 extends into the vapor-liquid separation bottle 54 from the bottom of the vapor-liquid separation bottle 54 . The bottom of the vapor-liquid separation bottle 54 is horizontal, and one side of the bottom is provided with a liquid phase outlet. One top end of the liquid phase flow pipe is connected with the liquid phase outlet, and the other end extends into the equilibrium tank 51 and communicates with the inside of the equilibrium tank 51 . The middle part of the vapor-liquid separation bottle 54 is recessed from the top to form a groove, that is, the cross-section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com