Torsional vibration damping device

A technology of torsional vibration damping and spring elements, applied in the direction of shock absorbers, transmissions, gear transmissions, etc., to achieve the effect of easy realization and reduced quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

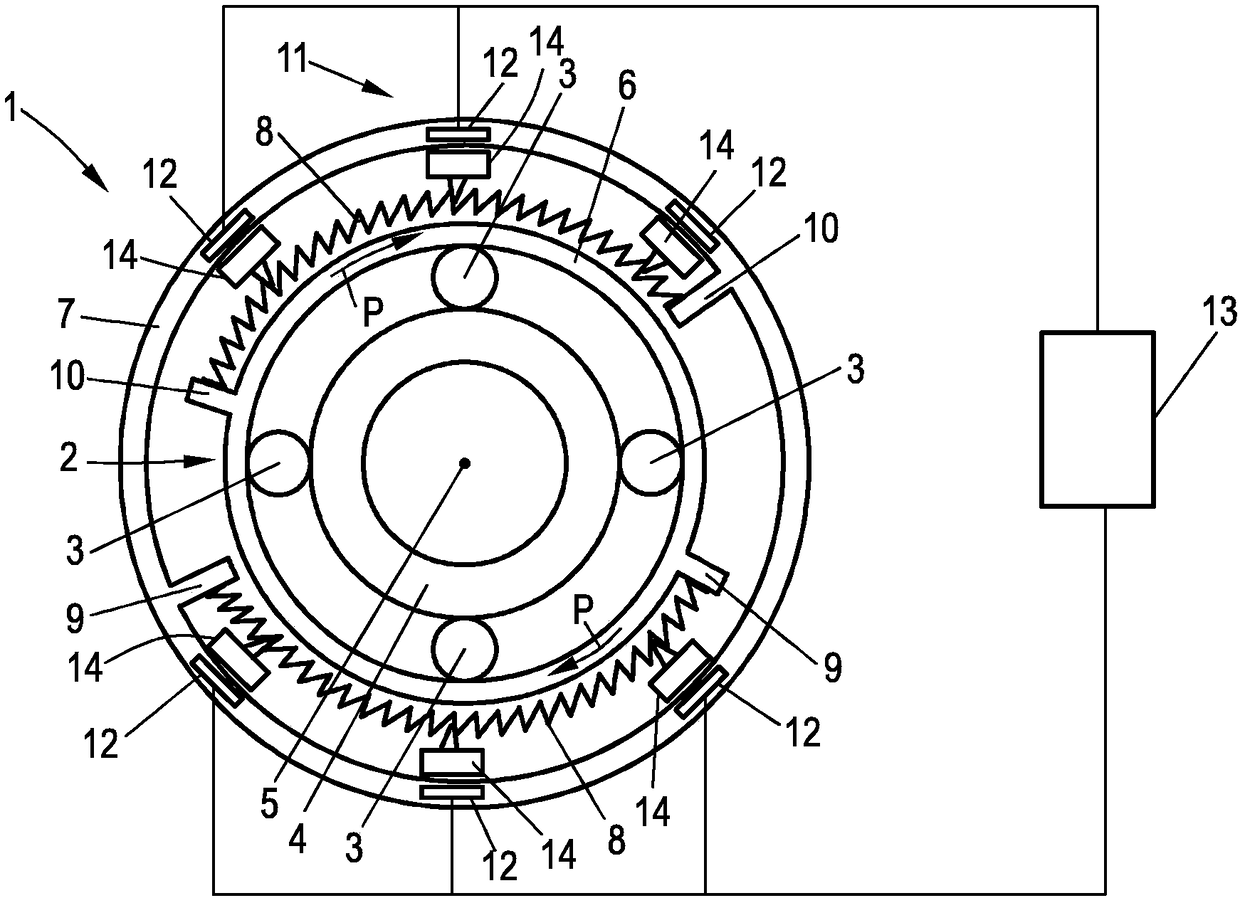

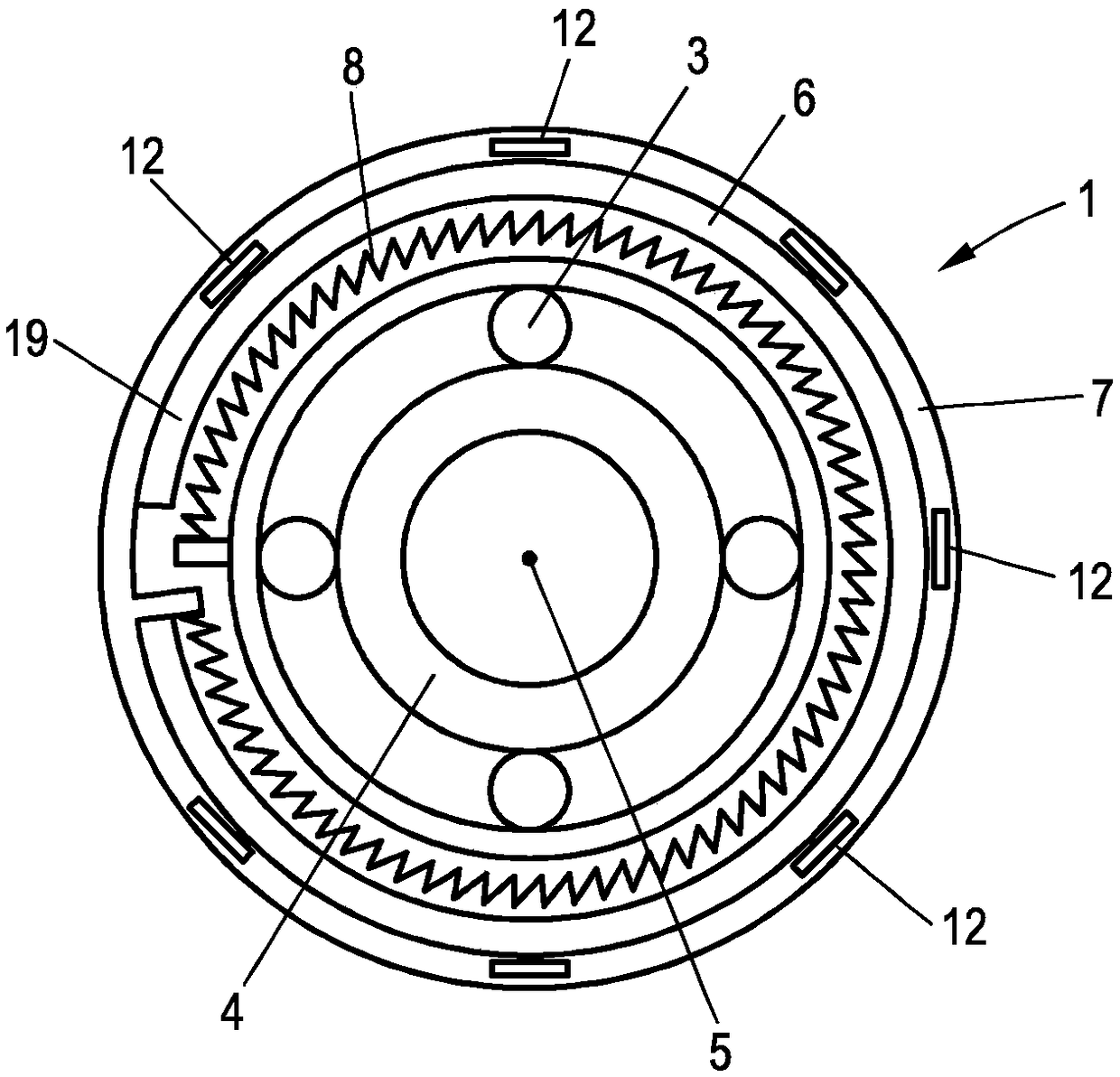

[0024] figure 1 A torsional vibration damping device 1 according to the invention is shown, comprising a planetary gear assembly 2 meshing with a plurality of planetary gears 3 with external toothing, said planetary gears interacting with externally toothed A drive pinion 4 meshes, which is connected to a drive shaft 5 , for example a crankshaft.

[0025]Furthermore, the planetary gear arrangement 2 includes a hollow gear 6 , the inner toothing of which the planet gears 3 also mesh with. The ring gear 6 itself is rotatable about the axis of rotation of the drive shaft 5 . The ring gear is accommodated in an outer ring component 7 which is, for example, part of the motor housing or the transmission housing or is fastened to such a motor housing or transmission housing. The ring gear 6 is supported relative to the stationary component 7 via two spring elements 8 , here in the form of bent helical springs. For this purpose, in the illustrated embodiment, two radial projections...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com