Conveying system for desulfurizing agent applied to dry desulfurization

A conveying system, dry desulfurization technology, applied in conveyors, conveying bulk materials, separation methods, etc., can solve problems such as conveying blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

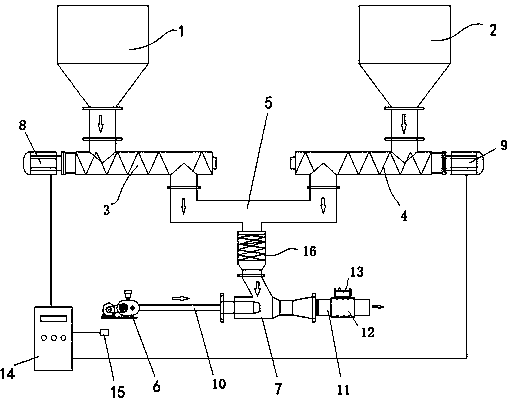

[0019] Such as figure 2 As shown, a delivery system for desulfurization agent used in dry desulfurization, including a first raw material bin 1, a second raw material bin 2, a first quantitative feeder 3, a second quantitative feeder 4, and a static mixer 16. Roots blower 6 and acceleration chamber 7, the first quantitative feeder 3 and the second quantitative feeder 4 are respectively connected to the first variable frequency motor 8 and the second variable frequency motor 9, and the first raw material bin 1 Connected with the first quantitative feeder 3, the second raw material warehouse 2 is connected with the second quantitative feeder 4, and the outlet ends of the first quantitative feeder 3 and the second quantitative feeder 4 are transported by the conveyor belt 5 The raw materials are transported to the static mixer 16, and the static mixer 16 is connected to the acceleration chamber 7. One end of the acceleration chamber 7 is connected to the Roots blower 6 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com