Movement planning method for mechanical arm

A technology of motion planning and robotic arm, applied in the field of robot control, can solve problems such as cumbersome process, achieve the effect of avoiding cumbersome process, improving control accuracy, and saving calculation amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Taking four degrees of freedom as an example, the construction process of the forward kinematics equation is as follows:

[0048] 1. In order to simplify the structure of the manipulator, the D-H parameters of the four-degree-of-freedom manipulator are set as follows:

[0049] D-H parameters of a four-degree-of-freedom manipulator

[0050] Connecting rod i

joint angle θ i

Torsion angle α i

Connecting rod length a i

Connecting rod offset d i

1

θ 1

0

l 1

0

2

θ 2

0

l 2

0

3

θ 3

0

l 3

0

4

θ 4

0

l 4

0

[0051] 2. Obtain the connecting rod transformation matrix of the manipulator through the D-H parameters:

[0052]

[0053]

[0054] where cθ 1 means cos(θ 1 ), sθ i Indicates that sin(θ i ), cθ 12 means cos(θ 1 +θ 2 ), sθ 1234 Indicates that sin(θ 1 +θ 2 ).

[0055] 3. The actual joint angle is set to θ=[0,π / 2,π / 4,0] T , the connectin...

Embodiment 2

[0060] Also taking the 4-DOF robotic arm as an example, the Jacobian matrix is constructed as follows:

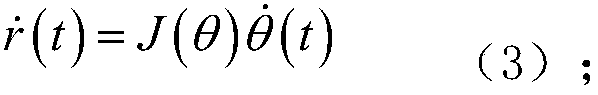

[0061] For a mechanical arm with a series structure with n degrees of freedom, the relationship between the Cartesian space motion velocity vector and the joint coordinate vector is:

[0062]

[0063] where i=1,2,...6 represent the number of translational linear velocity vectors and rotational angular velocity vectors of the end effector of the manipulator along the X, Y and Z directions respectively, and j=1,2,...n represent the number of joints of the manipulator number.

[0064] The 6×n Jacobian matrix is as follows:

[0065]

[0066] Since the four-degree-of-freedom robotic arm in this patent has 4 joints, and the robotic arm works in a two-dimensional plane, the specific Jacobian matrix involved is:

[0067]

[0068] where cθ 1 means cos(θ 1 ), sθ i Indicates that sin(θ i ), cθ 12 means cos(θ 1 +θ 2 ), sθ 1234 Indicates that sin(θ 1 +θ 2 ).

Embodiment 3

[0070] Taking the 4-DOF mechanical arm as an example, the whole process of the present invention is as follows:

[0071] The desired initial position joint angle of the robotic arm is set to [π / 6,π / 12,π / 6,0] T , the actual position of the robot arm is set to [0,π / 2,π / 4,0] T , the length of the four connecting rods is set to l=[1,0.8,0.7,0.5] T . Set the length of the four connecting rods of the robotic arm as l=[1,0.8,0.7,0.5] T , the task period T is 10s, λ 0 set to 5;

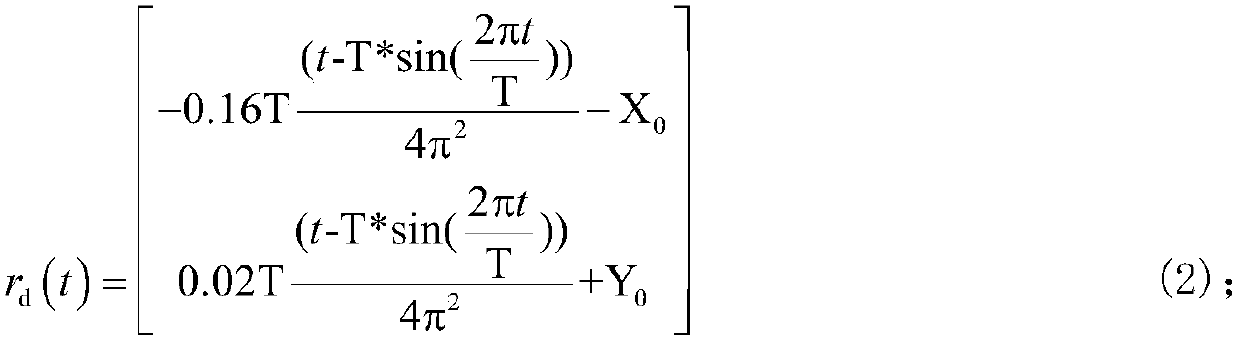

[0072] Parameter configuration when setting position deviation λ(t)=λ 0 [1-cos(2πt / T)],λ 0 is a scalar coefficient that can be set arbitrarily, and T represents the cycle of the manipulator to perform tasks;

[0073] First, set the desired joint angle θ of the manipulator d (0) and the actual joint angle θ(0) are respectively substituted into the following forward kinematics equation (1) for forward kinematics analysis of the manipulator:

[0074] r(t)=f(θ(t)) (1);

[0075] The expected initial posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com