Ammonium sulfate mother liquor concentration and distillation system and distillation process thereof

A distillation system and ammonium sulfate technology, applied in the direction of ammonium sulfate, evaporation, evaporator accessories, etc., can solve the problems of low distillation efficiency and poor distillation effect, and achieve high distillation efficiency, low environmental pollution, and good distillation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, illustrate the specific implementation manner of this embodiment

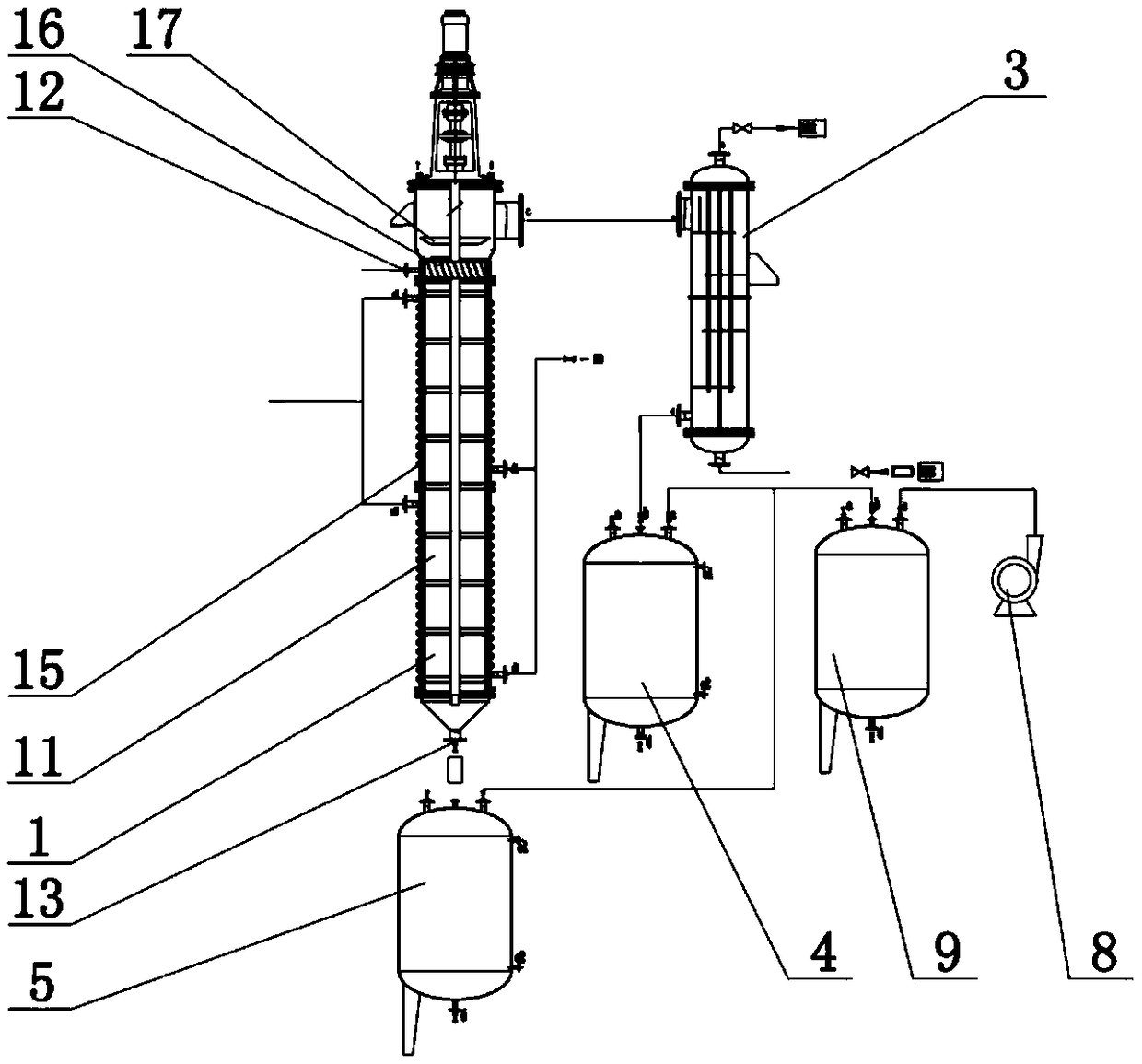

[0024] Such as figure 1 , figure 2 As shown, the concentrated distillation system for ammonium sulfate mother liquor in this embodiment includes a scraper thin-film evaporator 1 and a rake dryer 2. The evaporator 1 includes an evaporation chamber 11, and the evaporation chamber 11 is connected to the scraper 12 and the material distributor 16 through a rotating shaft. And the demister 17, the material distributor 16 can throw the material on the evaporation chamber 11 to ensure the evaporation effect. The demister can remove the material foam, prevent the material foam from being discharged with the water vapor, and also set the material inlet 12, concentrated liquid Outlet 13 and first steam outlet 14, a first heat exchange chamber 15 is arranged outside the evaporation chamber 11, the first steam outlet 14 is connected to the first condenser 3, the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com