Ceramic heating rod with ceramic core and electrode leads and production method of ceramic heating rod

A technology of electrode lead and ceramic heating, which is applied in the direction of ohmic resistance heating parts, ohmic resistance electrode, heating element shape, etc., can solve the problems such as the influence of the tensile performance of the electrode lead and the impact on production efficiency, so as to improve the brazing efficiency and improve Production efficiency and the effect of improving tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

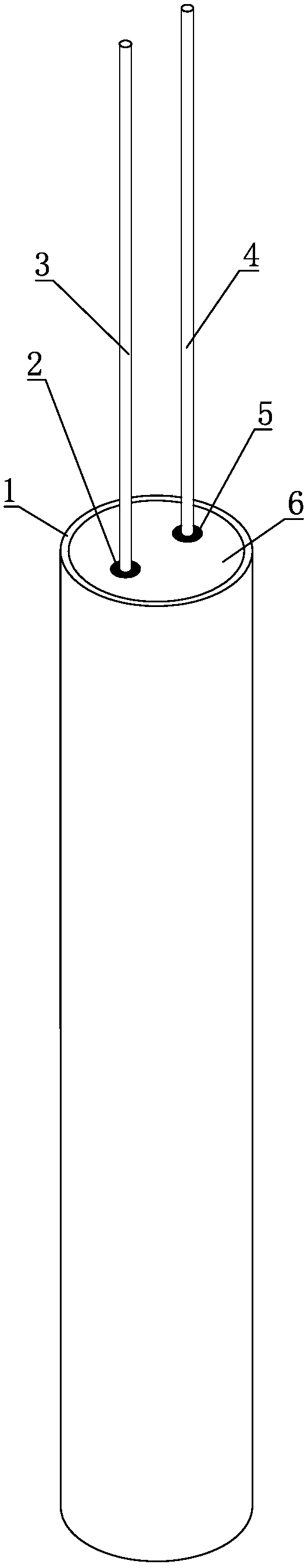

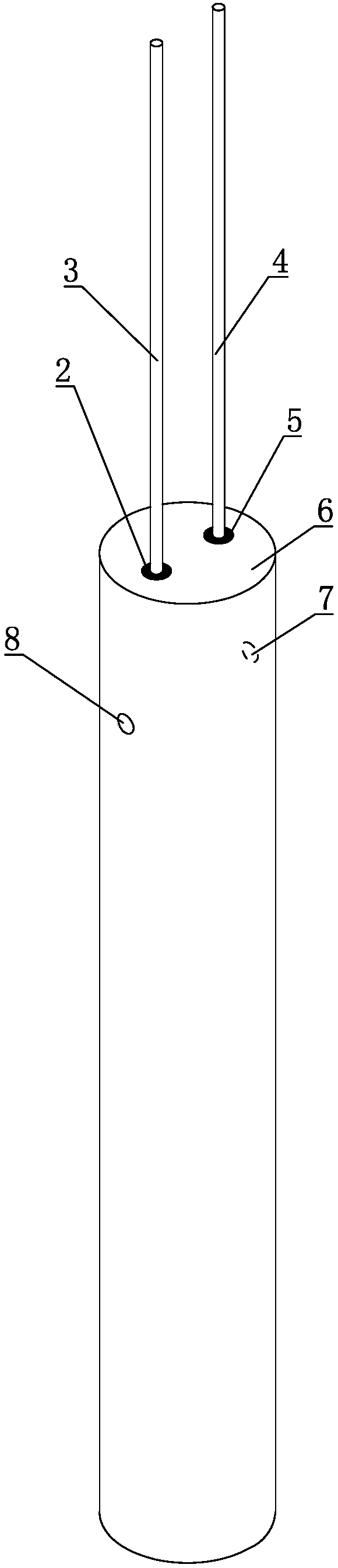

[0049] A ceramic heating rod with a ceramic core electrode lead, comprising: (a) a cylindrical ceramic lining core (6) and a curled ceramic sheet (1) tightly attached to the outer surface of the cylindrical ceramic lining core by sintering; (b) the first electrode lead ( 3) and the second electrode lead (4); the first land material sintered layer (19), first conductive circuit (18), heating circuit (17), second Conductive circuit (21), second connection pad material sintered layer (20). The improvement of the invention is that the cylindrical ceramic liner has a first electrode lead cavity and a second electrode lead cavity.

[0050] The first electrode lead cavity extends inwardly from the end surface of the cylindrical ceramic lining core, passes through the first electrode lead fillet cavity (9), and passes through the first connection hole (8) on the side wall. This is the cavity distribution and cavity orientation of the first electrode lead cavity in the cylindrical cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com