Heteroatom-doped porous carbon material and preparation method thereof and application in zinc-air battery

A technology of porous carbon materials and heteroatoms, applied in heteroatom-doped porous carbon materials and its preparation and application in zinc-air batteries, can solve the problems of low catalytic activity, limited material sources, and high preparation costs, and achieve improved Specific surface area, effect of enhancing catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

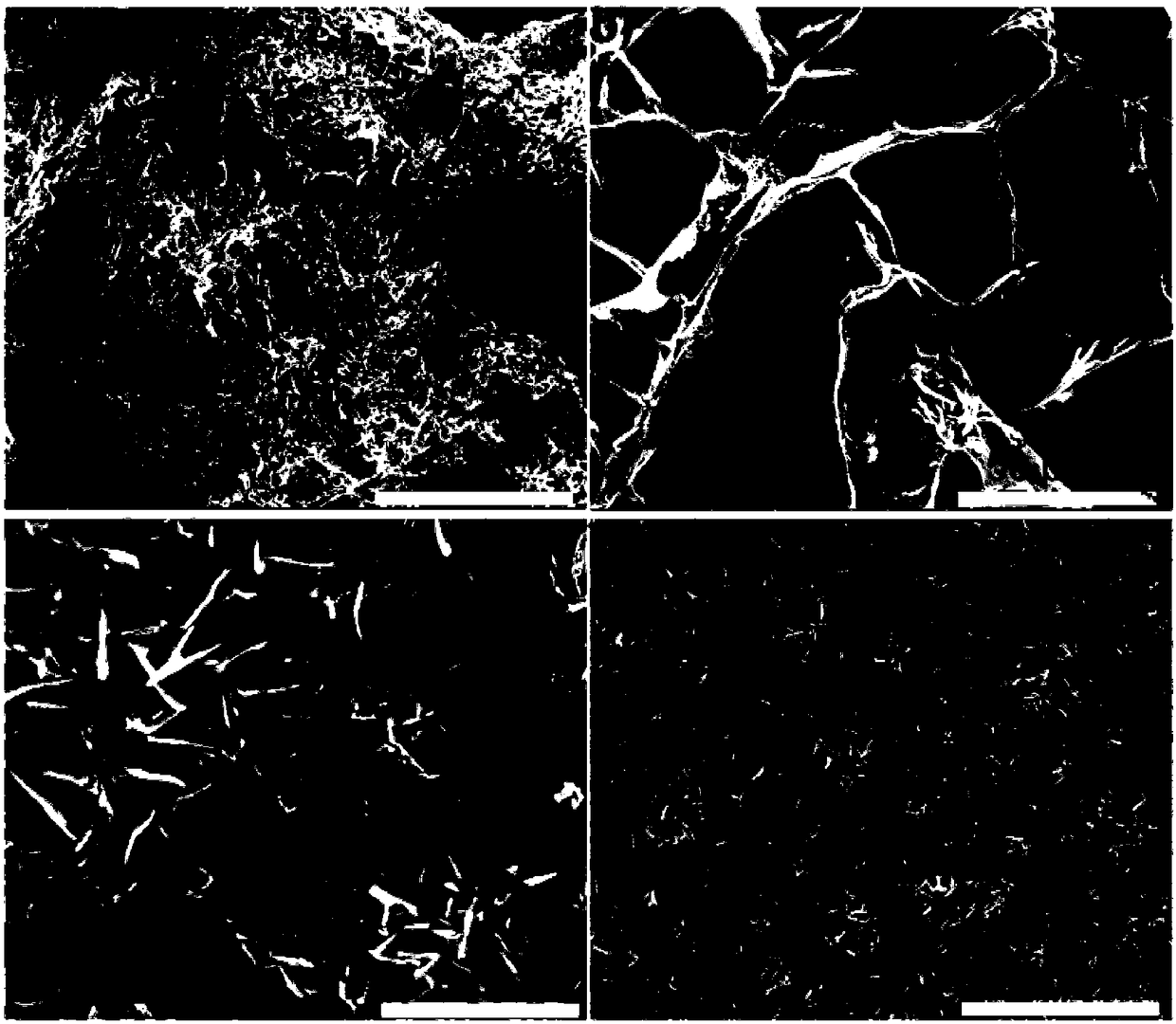

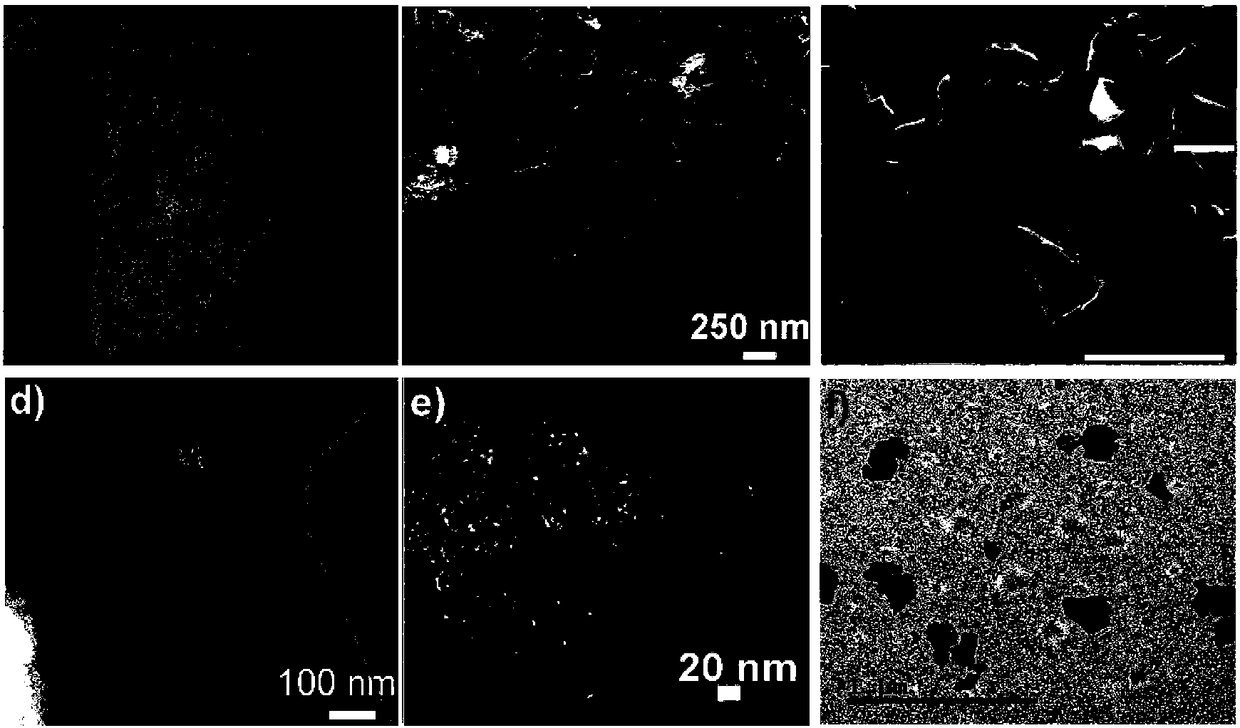

[0049] Step (1): Preparation of Biomass Self-Assembly

[0050] Dissolve 1.5 g of the biomass precursor BSA in 20 mL of water, add 8 mmol of sodium hydroxide, and keep stirring at room temperature. After 30 min, the biomass self-assembly can be obtained. Then, the water is removed by freeze-drying method, and the dry biomass self-assembly can be obtained.

[0051] Step (2): Obtaining heteroatom-doped porous carbon materials

[0052] Put the dry biomass self-assembly obtained in step (1) in a tube furnace, and carbonize at 900°C under an inert atmosphere to obtain a heteroatom-doped porous carbon material, denoted as BSA-8 -900, its specific surface area is 1274.1305m 2 g -1 , the pore size distribution is distributed in micropores, mesopores and macropores, showing a multi-level pore distribution.

[0053] Step (3): Test of oxygen reduction reaction of carbon materials and assembly and testing of zinc-air batteries:

[0054] 1. Wash the obtained carbon material several tim...

Embodiment 2

[0058] Step (1): Dissolve 1.5 g of the biomass precursor BSA in 20 mL of water, add 8 mmol of sodium hydroxide, and keep stirring at room temperature. After 30 min, the biomass self-assembly can be obtained. Then, the water is removed by freeze-drying method, and the dry biomass self-assembly can be obtained.

[0059] Step (2): Obtaining heteroatom-doped porous carbon materials

[0060] Put the dried biomass self-assembled body obtained in step (1) in a tube furnace, and carbonize it at 700°C under an inert atmosphere to obtain a heteroatom-doped porous carbon material, denoted as BSA-8 -700, which has a surface area of 548.7413m 2 g -1 , the pore size distribution is mainly concentrated in the micropore area, and there is a small amount of distribution in the macropore area.

[0061] Step (3): Test of oxygen reduction reaction of carbon materials and assembly and testing of zinc-air batteries:

[0062] 1. Wash the obtained carbon material several times with secondary wa...

Embodiment 3

[0066] Step (1): Dissolve 1.5 g of the biomass precursor BSA in 20 mL of water, add 8 mmol of sodium hydroxide, and keep stirring at room temperature. After 30 min, the biomass self-assembly can be obtained. Then, the water is removed by freeze-drying method, and the dry biomass self-assembly can be obtained.

[0067] Step (2): Obtaining heteroatom-doped porous carbon materials

[0068] Put the dry biomass self-assembly obtained in step (1) in a tube furnace, and carbonize at 500°C under an inert atmosphere to obtain a heteroatom-doped porous carbon material, denoted as BSA-8 -500, its specific surface area is 17.3566m 2 g -1 , the pore size distribution mainly has a small amount of distribution in the macropore area.

[0069] Step (3) Oxygen reduction reaction test of carbon materials and zinc-air battery assembly and testing:

[0070] 1. Wash the obtained carbon material several times with secondary water, and after vacuum drying, take a small amount of carbon material, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore size distribution range | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com