Overhead steel frame and mounting method thereof

A steel frame and support frame technology, which is applied to floors, local raised floors, buildings, etc., can solve problems such as poor structural stability of overhead systems, difficulty in leveling the chassis, and shaking of the bathroom floor. Clean, firmly installed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the drawings and embodiments:

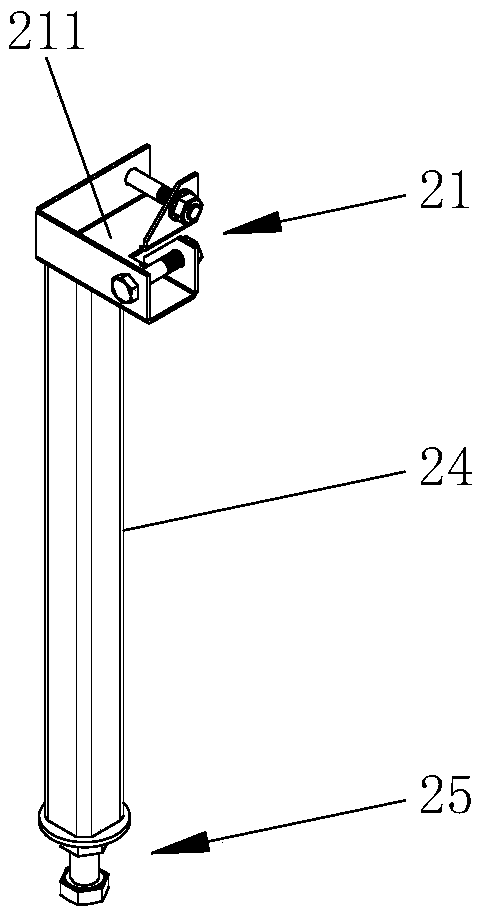

[0037] Such as Figure 1 to Figure 6 As shown, the overhead steel frame of this embodiment has a keel 1, a vertical support frame 2 and a transverse support frame 3. The keel 1 constitutes a rectangular platform with a notch in one corner, and the keel 1 in the rectangular platform is in a grid shape. ; Vertical support frame 2 includes L-shaped keel support frame 2a, T-shaped keel support frame 2b and cross-shaped keel support frame 2c, L-shaped keel support frame 2a, T-shaped keel support frame 2b and cross-shaped keel support frame 2c all include The bending piece, the support column 24 and the height adjustment mechanism 25. The bending piece is fixed on the upper head of the support column 24 and bolted to the keel 1, and the height adjustment mechanism 25 is fixed on the lower head of the support column 24 to adjust the support column 24 And the vertical support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com