Buoyancy adjusting pump system for kilometric underwater glider

An underwater glider and buoyancy adjustment technology, which is applied to underwater ships, underwater operating equipment, pumps, etc., can solve the problems of unfavorable maneuverability of underwater glider underwater navigation, insufficient oil absorption capacity of miniature axial plunger pumps, and buoyancy adjustment Problems such as long process cycle can be achieved to improve the ability to deal with the load marine environment, improve flexibility and mobility, and achieve the effect of short cycle working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

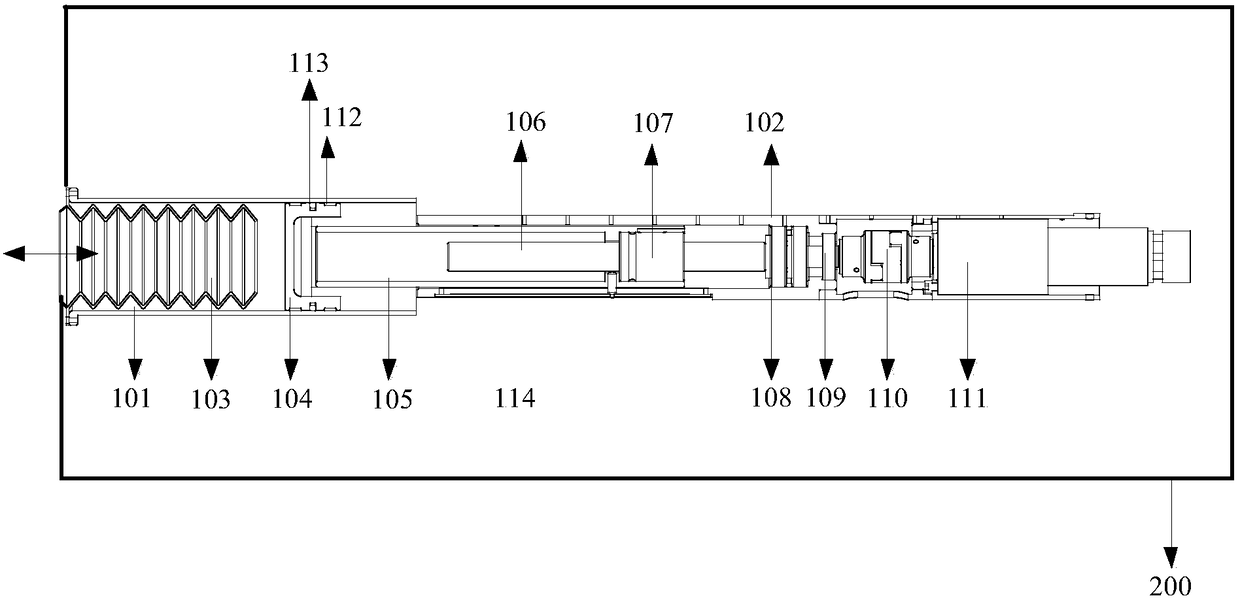

[0019] see Figure 1 ~ Figure 3 , a buoyancy adjustment pump system for a kilometer-level underwater glider, including a piston cylinder 101 and a transmission support cylinder 102 arranged longitudinally from front to back inside the cabin body 200, the piston cylinder 101 is provided with a The front end is open, the rear end of the piston cylinder 101 is fixedly connected to the transmission support cylinder 102, and a corrugated telescopic tube 103 and a piston 104 coaxially arranged in the piston cylinder 101 are installed. The corrugated telescopic tube 103 is arranged in front of the piston 104, and the two are separated. The front end of the piston cylinder 101 is open, the rear end of the corrugated telescopic tube 103 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com