A Welding Method Using Cast Iron Platform to Control the Levelness of Tower Skirt Foundation

A cast iron platform, welding method technology, applied in welding equipment, manufacturing tools, metal processing equipment and other directions, can solve the problem of difficult control of welding deformation, improve bearing capacity and stability, reduce correction work, reduce manpower and material resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

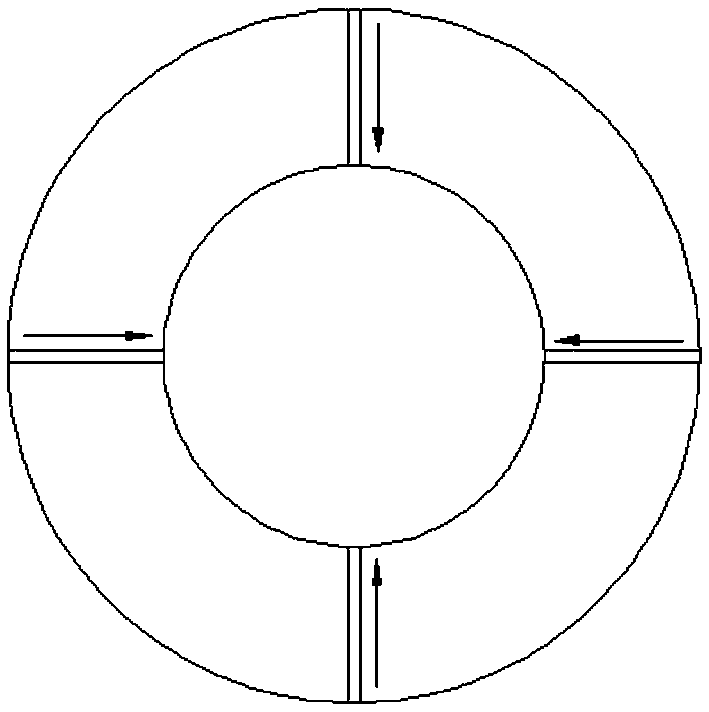

[0053] Embodiment: the present invention uses 60000Nm 3 The rectifying tower of the air separation equipment of / h is taken as an example to illustrate the technical scheme of the present invention. The material of the tower is 5083, and the diameter of the tower is 4500mm.

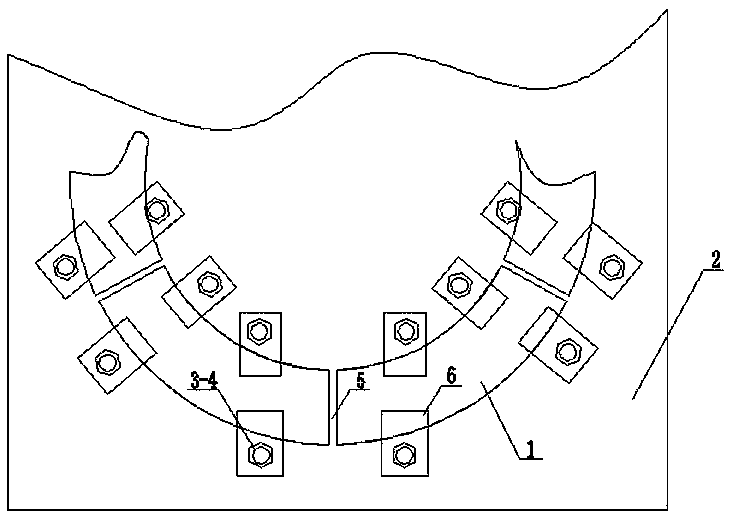

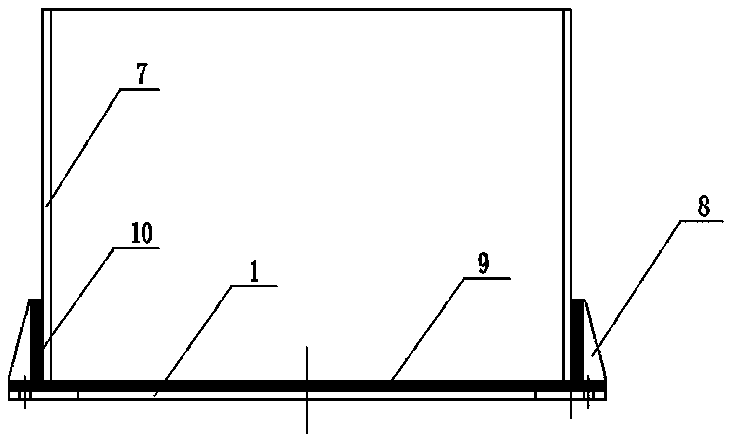

[0054] Groove the base ring plate 1 that has been blanked according to the welding process, place the ring plate to be spliced on the cast iron platform 2, draw a line on the platform according to the diameter of the cylinder, adjust the root gap to 1-2mm, and prepare for pre-processing. assembled.

[0055] Place the stud 3 in the T-shaped groove of the platform, adjust it to the area of the spliced weld 5 (as close as possible to the weld without affecting the welding), and then place a backing plate with the same thickness as the foundation ring plate at the corresponding position, and then use The pressing plate 5 with holes matched with the stud presses the base ring plate, and finally the nut ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com