Control auxiliary device for system operation in pressure casting industry

An auxiliary device and an industry-leading technology, which is applied in the field of system control auxiliary devices, can solve the problems of inconvenient winding and arrangement of electrical connecting wires, poor lying comfort of the support plate, and difficulty in timely wiping, so as to achieve convenient removal or installation and fixing actions, Easy to wind and organize, improve the effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

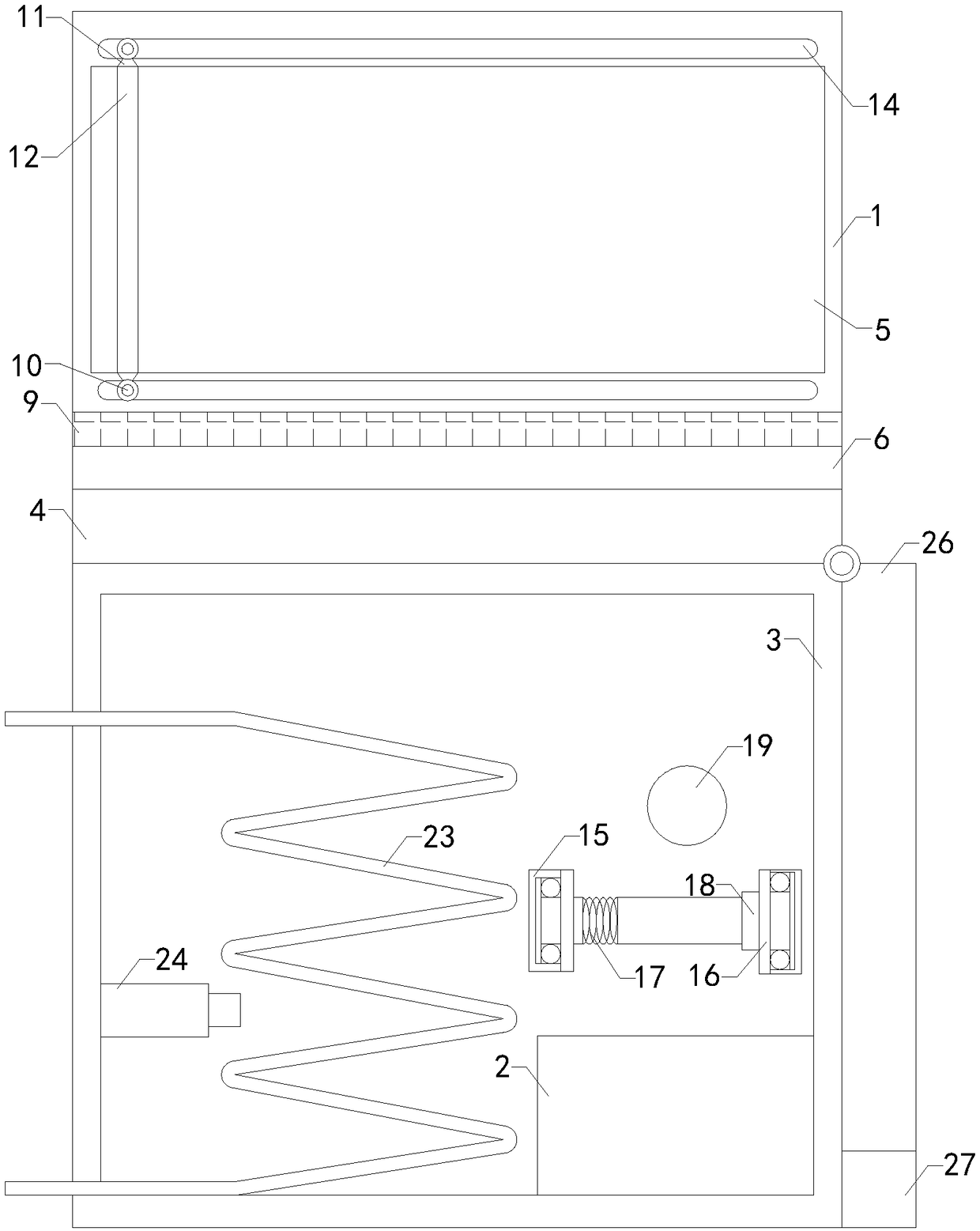

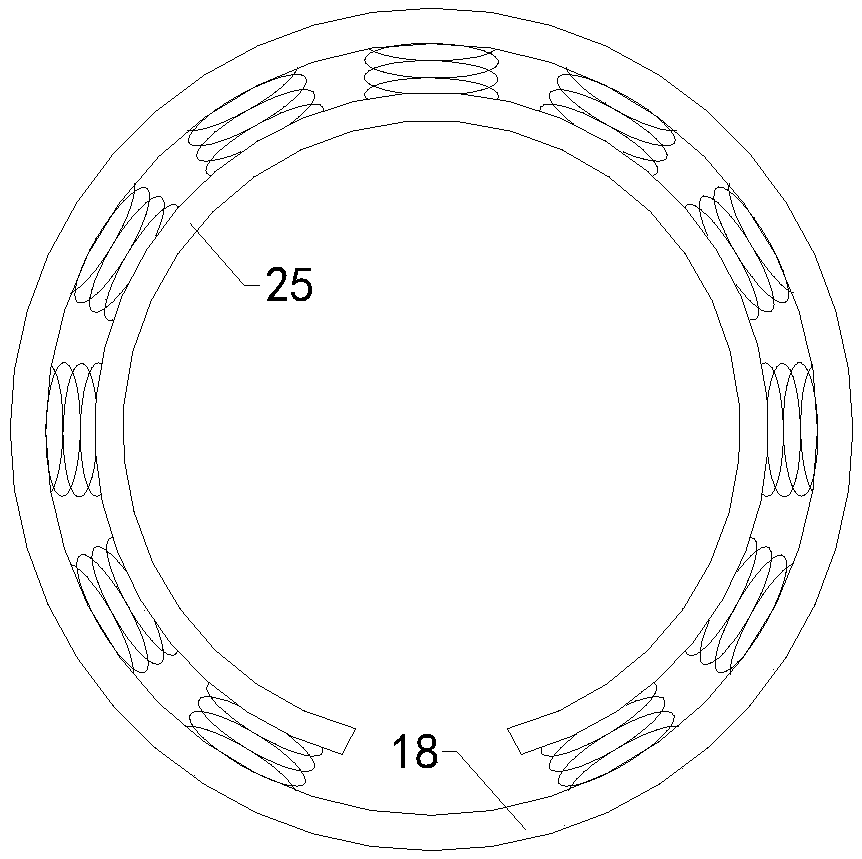

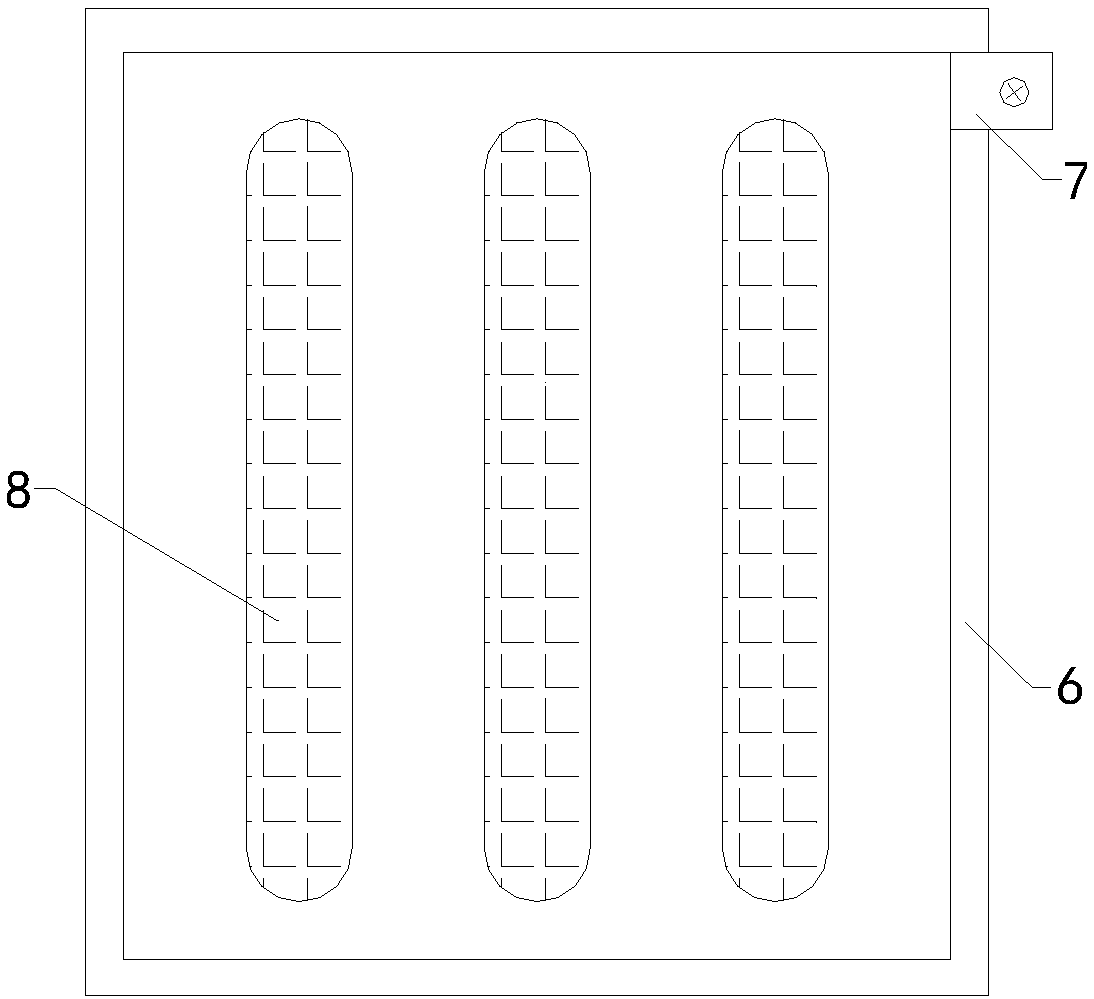

[0019] Such as Figure 1 to Figure 4 As shown, a control auxiliary device for system operation in the die-casting industry of the present invention includes a controller 1, a host computer 2, a placement frame 3 and a support plate 4, the support plate is installed on the top of the placement frame, and a placement cavity is provided inside the placement frame , and the front side wall of the placement frame is connected with a pick-and-place opening, the controller is installed on the top of the support plate, the front side of the controller is provided with a display screen 5, and the host is placed on the bottom side wall of the placement cavity; it also includes an ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com