Reinforced composite film and manufacturing method therefor

A technology of composite reinforcement and reinforcement layer, applied in chemical instruments and methods, instruments, optics, etc., can solve the problems of unable to maintain the original shape, tearing, wrinkles, etc., to reduce the preparation process and preparation cost, not easy to break, easy to carry and moving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, an embodiment of the present invention will be described with reference to the accompanying drawings. If there is no special requirement, the reference numerals involved in the background technology and the previously described structures will be used.

[0030] Moreover, the description of the composite reinforced membrane and the preparation method of the present invention only belong to the preferred embodiment, the present invention is not limited to this embodiment, and can be embodied in various embodiments, and the shape and size of each structure are only representative The category of embodiments is not fixed, and as long as the same or similar effects can be realized, various changes can be made to the present invention.

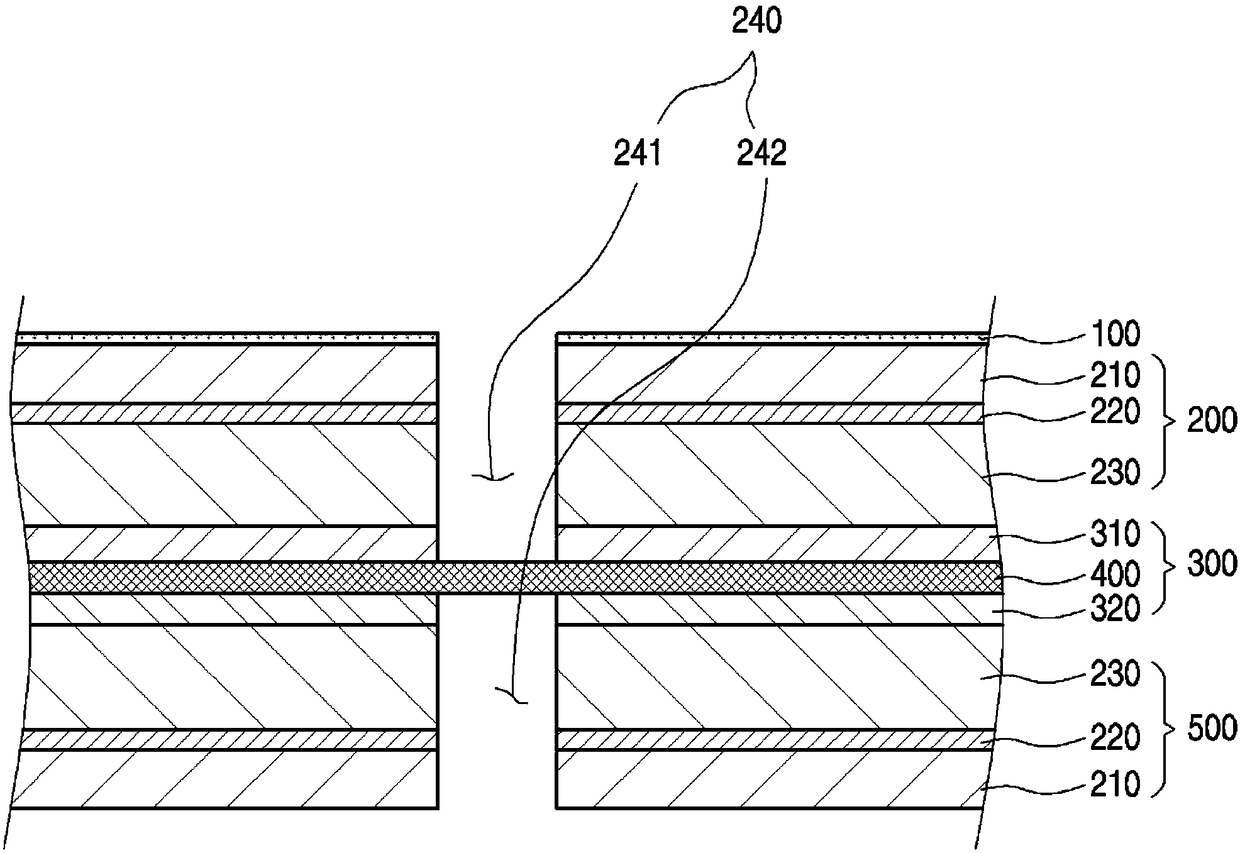

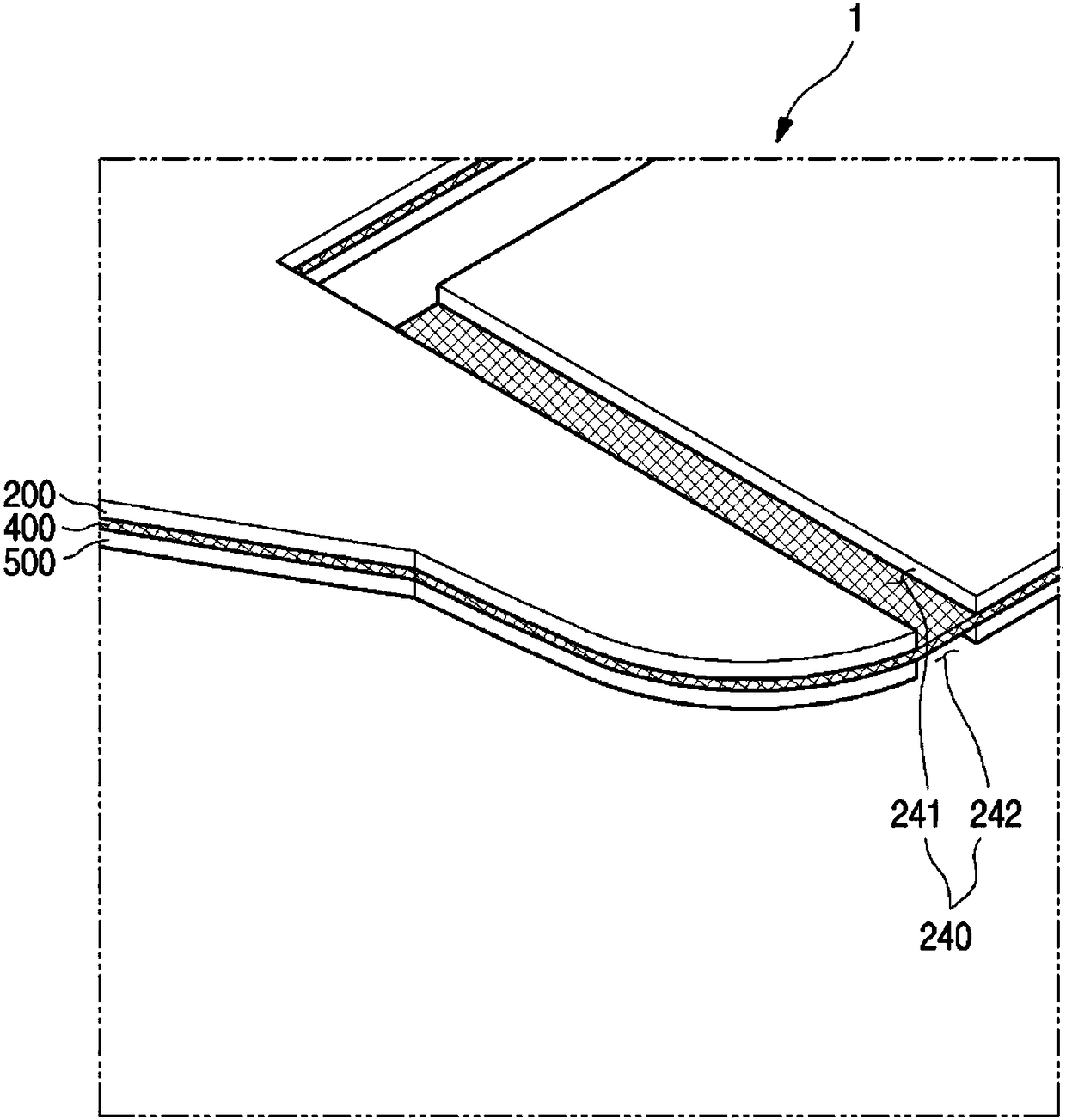

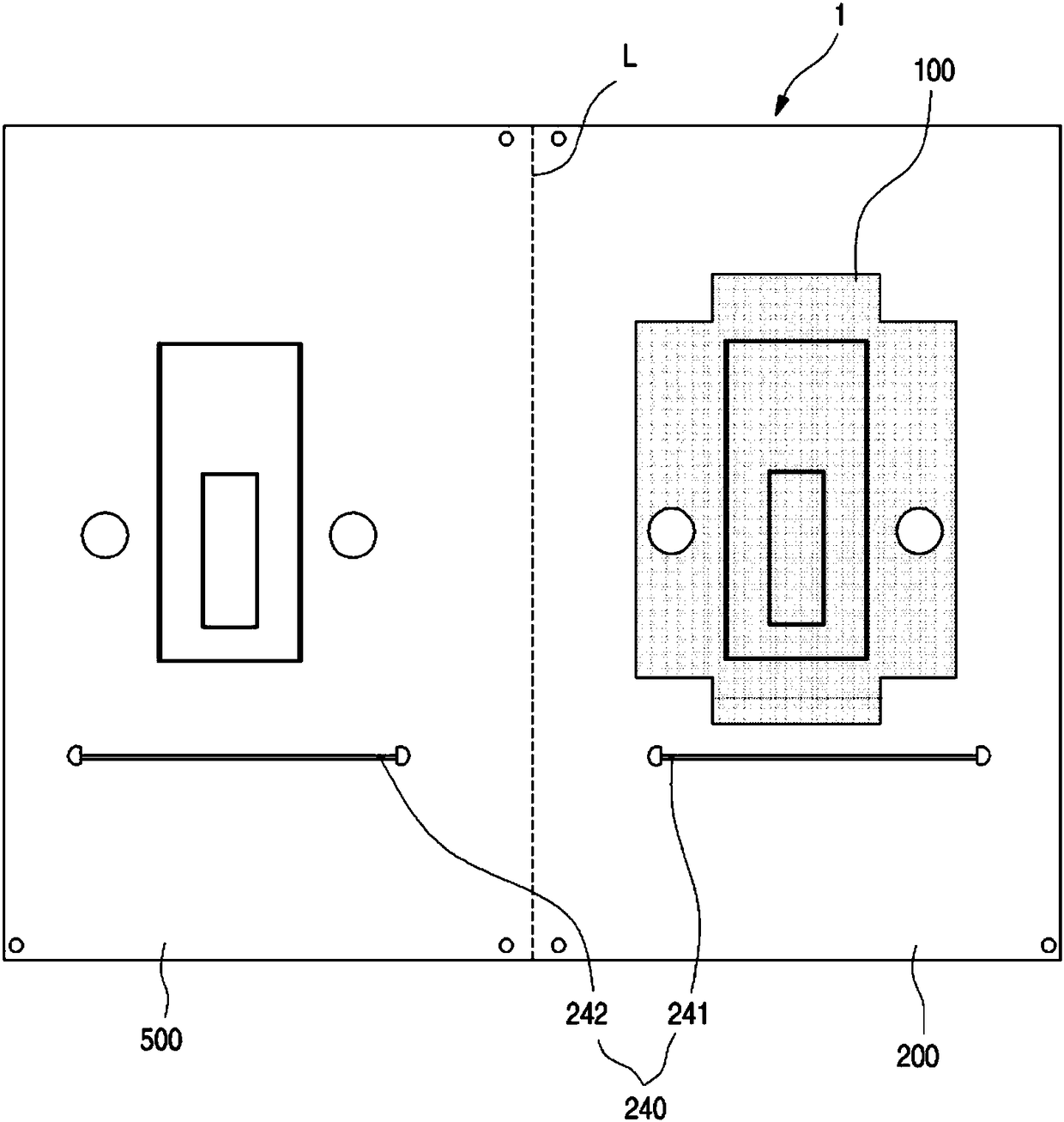

[0031] like Figure 1 to Figure 4 As shown, the composite reinforced film 1 according to an embodiment of the present invention includes a first flexible layer 200 , a second flexible layer 500 , a mesh layer 400 and a main bondi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com