Rheometer

A technology of rheometer and flow characteristics, which is applied in the field of rheometer, can solve the problems that it is impossible to simulate or study the plasticizing screw, etc., and achieve the effect of high quality and reproducible production process quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

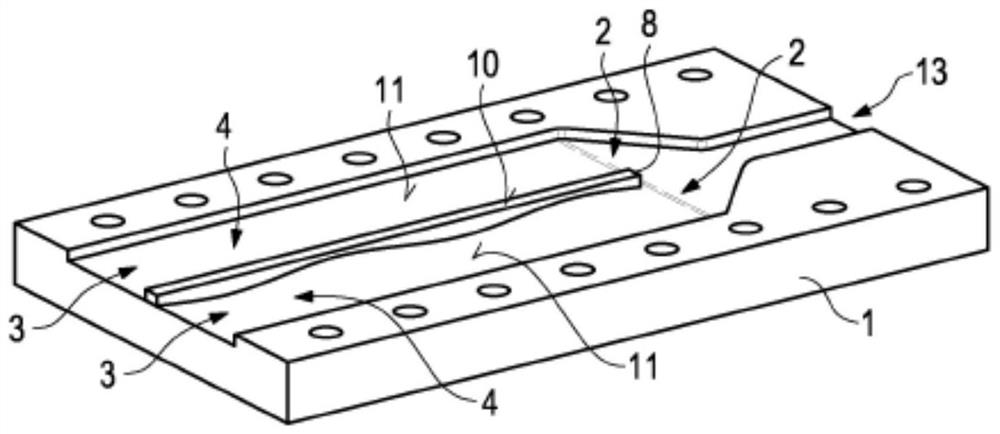

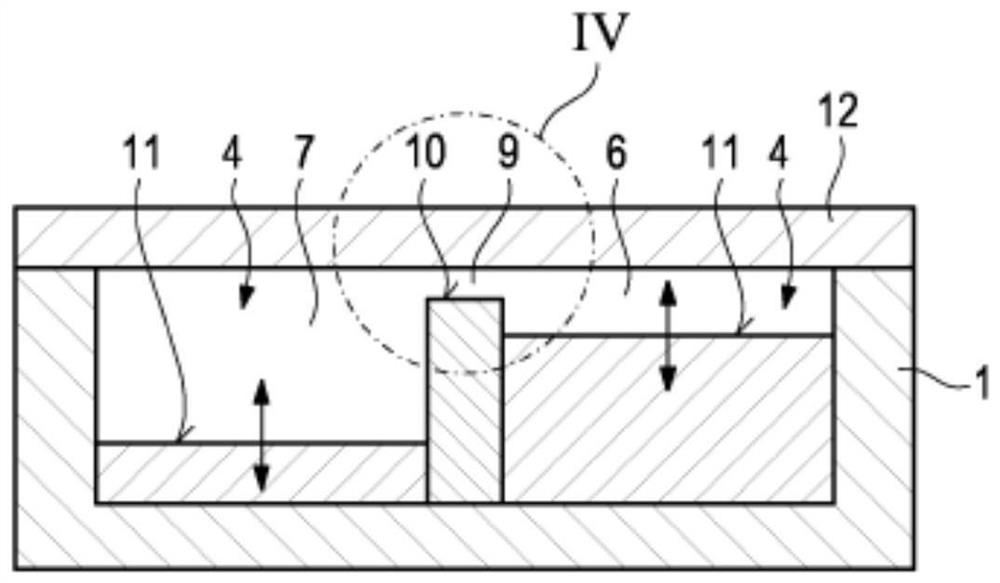

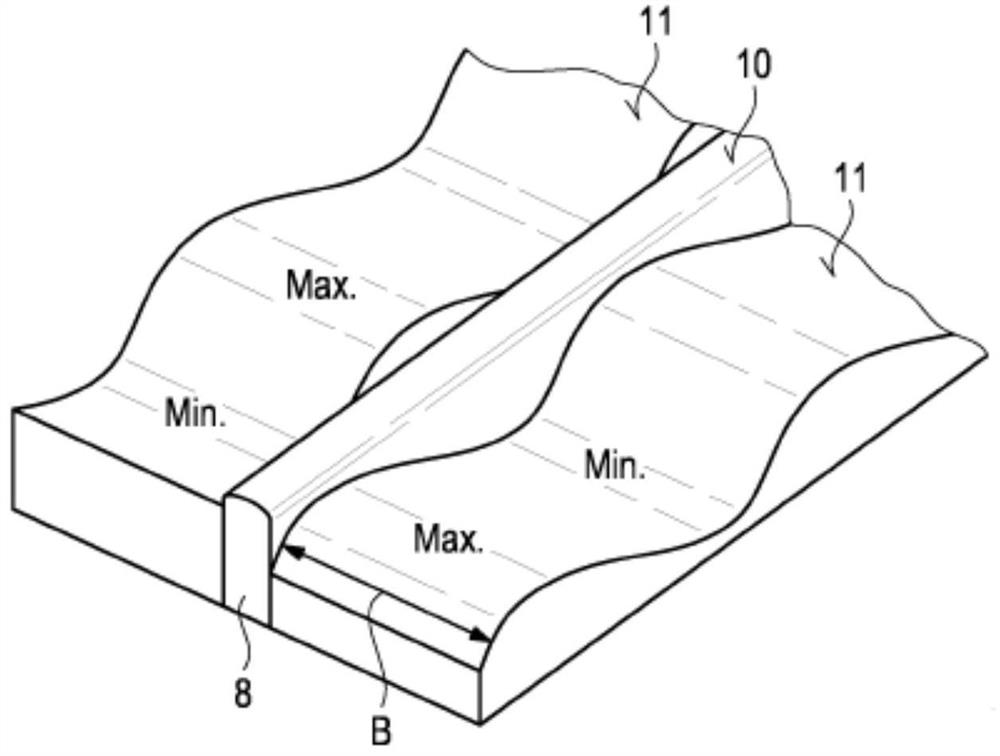

[0054] figure 1 An exemplary embodiment of a rheometer according to the invention is shown in an open state. in this regard, figure 2 A cross-sectional view for illustration is shown. The rheometer has a housing 1 in which two channels 4 are formed parallel to each other. The two channels 4 are separated from each other by a web 8 which can be made detachable. The web 8 has a top edge 10 which is spaced from the inner wall of the cover plate 12 . This spacing creates a gap 9 (see especially figure 2 and Figures 4a to 4c ).

[0055] Such as figure 1 As shown, the housing is provided with an inflow distributor 13 which distributes the inflowing fluid substance to the inlets 2 of the two parallel channels 4 . The fluid thus flows through the channel 4 and exits through the outlet 3 . For illustrative purposes, Figure 5 This arrangement is shown again in . Figure 5 Also shown is a further pump 14 which can be provided for delivering fluid.

[0056] In the area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com