Variable stiffness spring type constant flow valve

A technology of variable stiffness springs and constant flow valves, applied in the field of hydraulic valves, can solve problems such as small flow area, complex flow field, and large flow resistance, and achieve the effects of large flow area, simple flow field, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

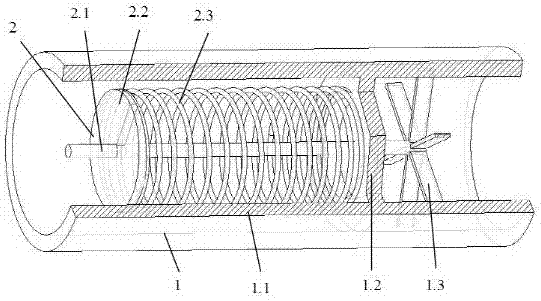

[0018] Such as figure 1 with figure 2 As shown, a variable stiffness spring type constant flow valve, the valve body 1 is mainly composed of a cylindrical shell 1.1, a retaining ring 1.2 and a fixed support 1.3 sequentially fixed in the shell 1.1. The spool 2 includes a guide rod 2.1 fixed on the fixed support 1.3, a baffle plate 2.2 that is installed on the guide rod 2.1 and can slide along the guide rod 2.1, and a variable stiffness spring 2.3 connected between the baffle plate 2.2 and the retaining ring 1.2. The retaining ring 1.2 is a circular plate with a circular hole in the center. The periphery of the retaining ring 1.2 is fixedly connected with the inner wall of the housing 1.1 to ensure sealing. The inner diameter of the retaining ring 1.2 is smaller than the diameter of the variable stiffness s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com