Connector terminal capable of improving opposite insertion retention force

A connector terminal and retention force technology, which is applied in the field of connector terminals to improve the mating retention force, can solve the problems of insufficient connection force, easy loosening and failure of connector terminals and pins, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

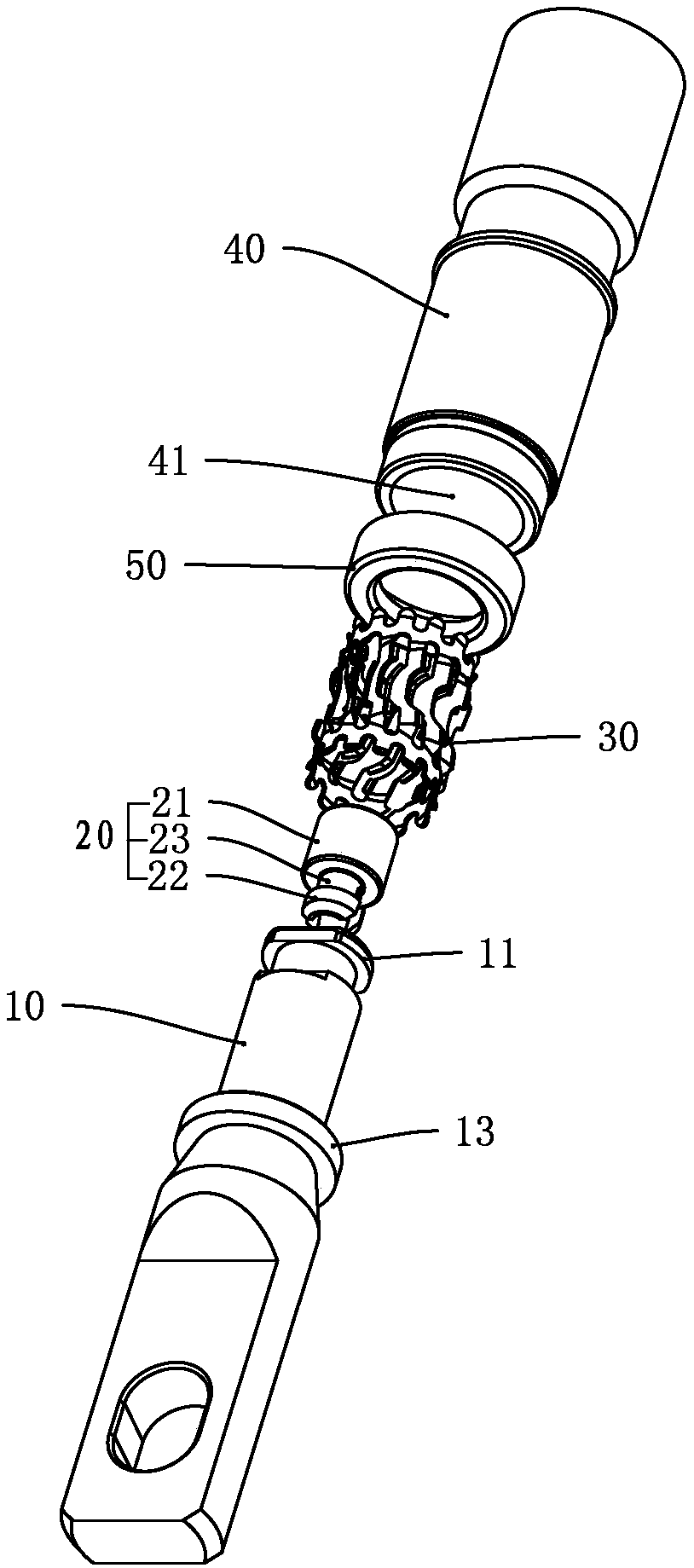

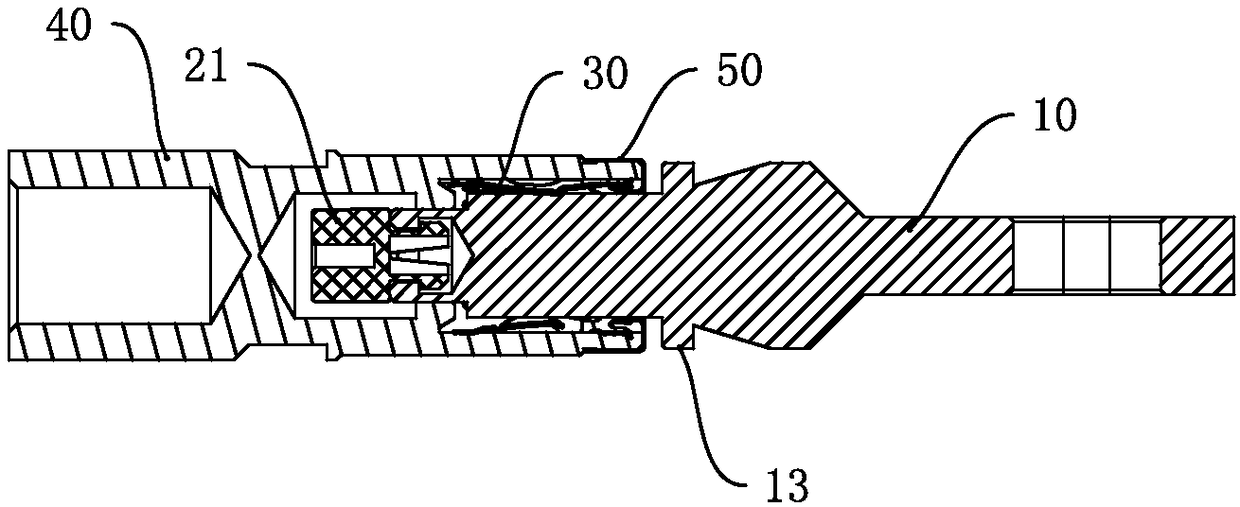

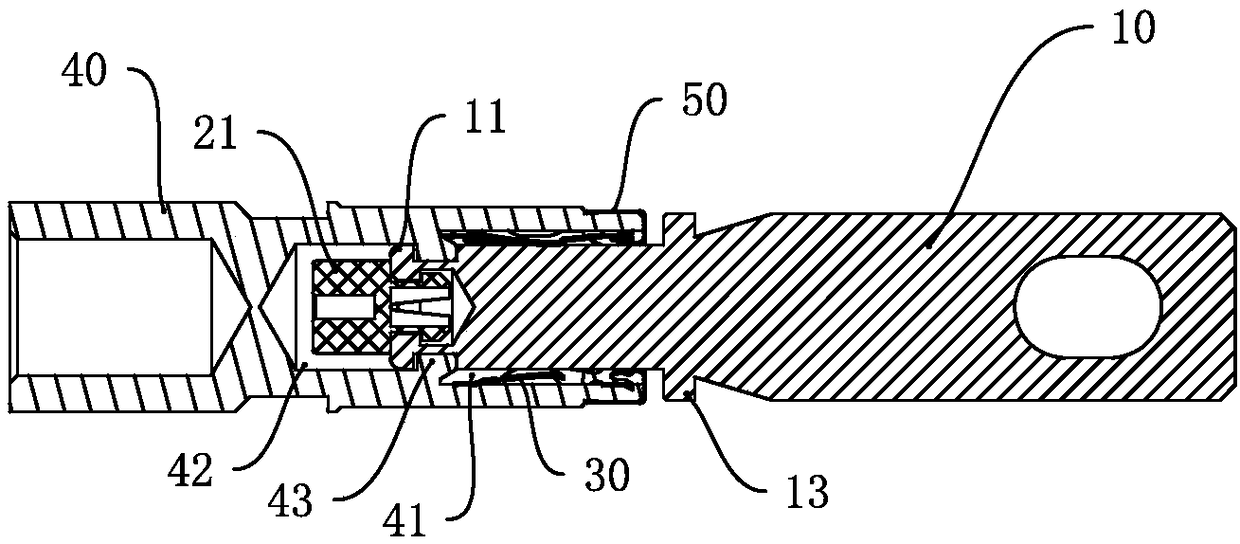

[0018] Such as Figure 1 to Figure 6 As shown, a connector terminal that improves mating retention force includes a pin 10, a protective cap 20, a scale spring 30 and a socket 40. The front end of the socket 40 is concavely provided with a jack 41, and the scale spring 30 is locked. Closely arranged in the socket 41, the socket 41 extends along the axial direction to the rear end of the socket 40 with a first receiving groove 42, and the opposite sides of the inner wall of the first receiving groove 42 are respectively provided with a stopper 43, and the two stoppers 43 form a card interface, the outer wall of the insertion end of the pin 10 is provided with an annular protrusion 11, and the annular protrusion 11 is cut with a gap, and the diameter of the annular protrusion 11 is greater than the distance between the two gear parts 43. The diameter is smaller than the diameter of the first receiving groove 42, the insertion end of the pin 10 is clamped with the protective cap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com