Quick butt joint tail end connecting device

A connection device and fast technology, applied in the field of robotics, can solve the problems of debris pollution, unsuitable screwdrivers, inconvenient handling and connection, etc., and achieve the effect of simplifying alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028]下面将结合本发明实施例中的附图,对本发明实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施例仅仅是本发明一部分实施例,而不是全部的实施例。基于本发明中的实施例,本领域普通技术人员在没有作出创造性劳动前提下所获得的所有其它实施例,都属于本发明保护的范围。

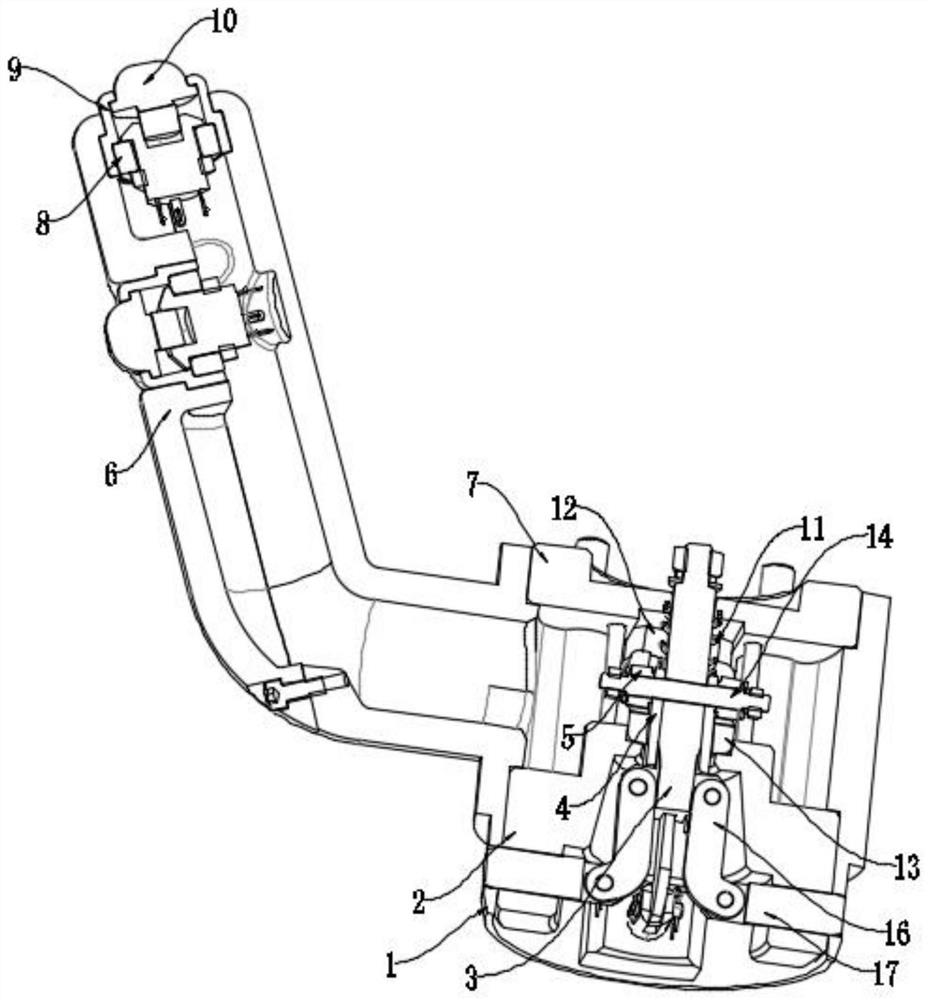

[0029]请参阅图1-6,本发明提供一种技术方案:

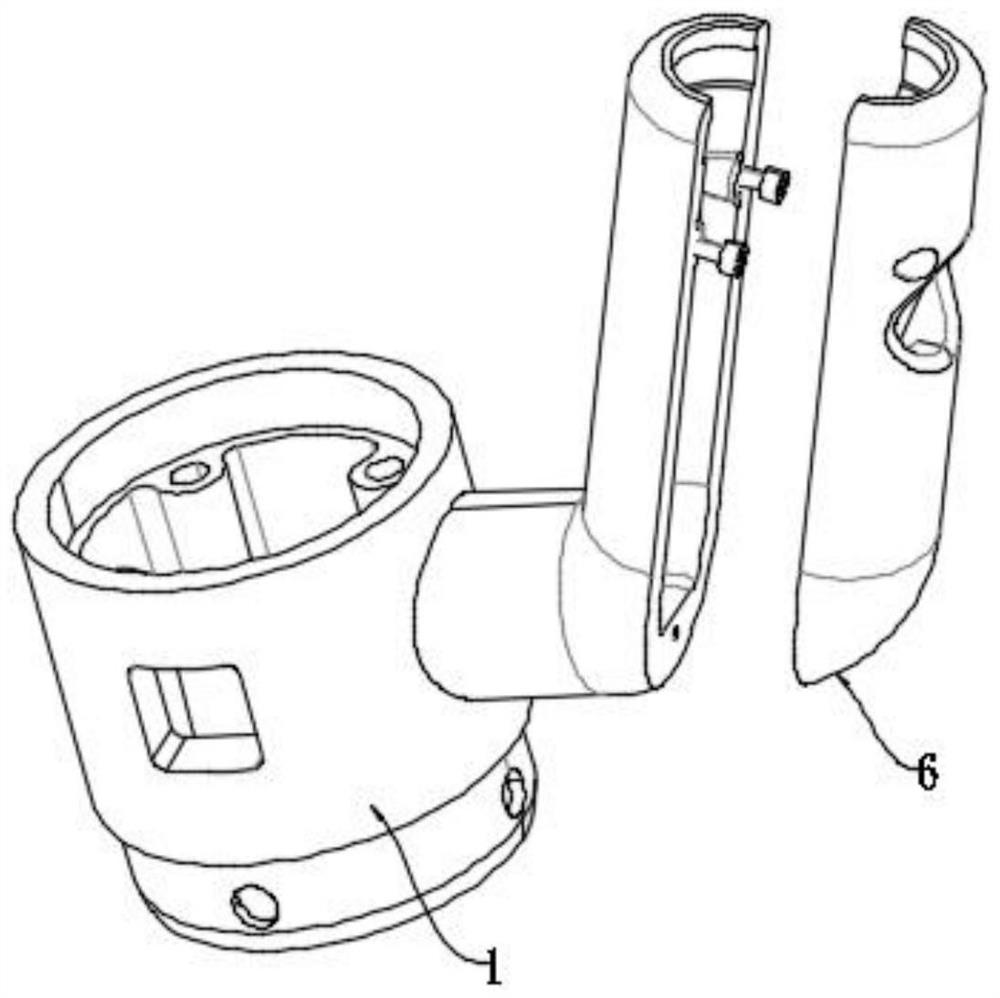

[0030]一种快速对接末端连接装置,包括外支座1与底座22,底座22内腔开设有锥形空腔21,连接装置还包括有:

[0031]外支座1外表壁固定连接的手柄盖6;

[0032]开设在外支座1内表壁的接头空腔,且接头空腔内表壁固定安装有呈竖直分布的上端盖7与内支座2,内支座2与上端盖7之间通过螺栓拉紧固定;

[0033]上端盖7中部设置有升降轴3,升降轴3外表壁套接有与上端盖7底部固定连接的拉杆弹簧11,且拉杆弹簧11底部固定连接有挡套4,挡套4套设在升降轴3外表壁,升降轴3与挡套4之间沿轴心垂直插接有拨轴14,拨轴14两侧均固定安装有辊子5;

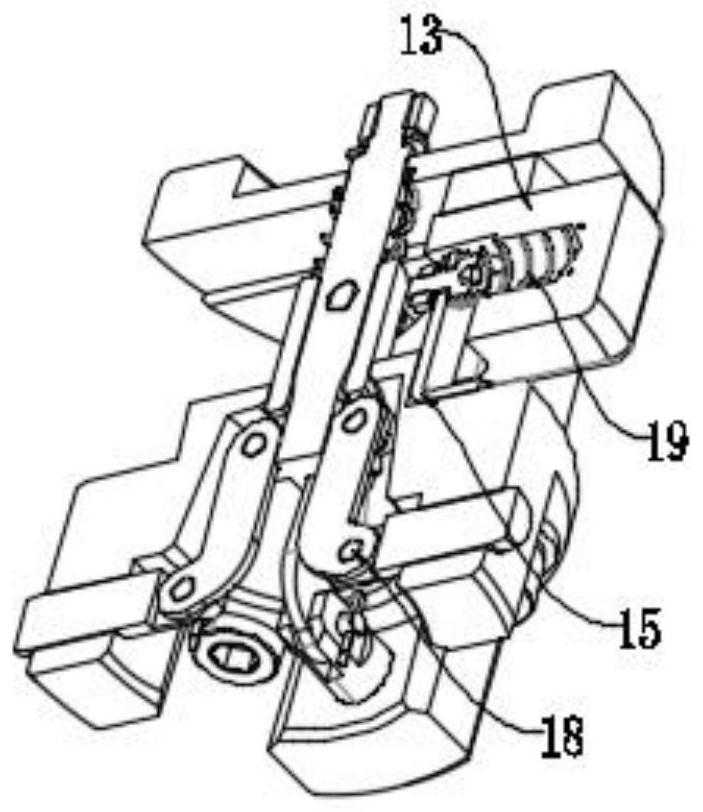

[0034]升降轴3下端分别通过四组连板销18活动连接有四组连板主体16,且四组连板主体16另一端均通过销钉铰接有锁扣主体17,四个锁扣主体17均可沿内支座2环面分布的四个孔运动;

[0035]外支座1内表壁水平穿设有锁扣按钮13,锁扣按钮13内表壁滑动连接有与外支座1内表壁固定连接的弹簧挡板15,且弹簧挡板15与外支座1内表壁之间弹性连接有按钮弹簧19。

[0036]按压锁扣按钮13,辊子5沿滑道滚动上升,辊子5通过拨轴14带动升降轴3上升,同时挤压拉杆弹簧11,升降轴3带动四个连板主体16运动,四个连板主体16分别拉动四个锁扣主体17,锁扣主体17在内支座2环面分布的四个孔内收紧,锁扣按钮13按压到位,接触弹簧挡板15,从而与对接底座22完全分离,当松开锁扣按钮13时,被挤压的按钮弹簧19弹性拉伸 / 恢复,使锁扣按钮13复位,拉杆弹簧11弹性拉伸 / 恢复挤压挡套4,带动通过拨轴14与其相连的升降轴3下降,依次带动四个连板主体16、四个锁扣主体17运动,使四锁扣主体17处于外凸状态,将末端接口插入对接底座22时,底座22上的锥形空腔21与末端接头锥形外缘便于装配,圆头锁扣可以无干涉地滑入底座22内的锥形空腔21,锥形空腔21挤压锁扣主体17,反向挤压拉杆弹簧11,直到抵达底座22对接沟槽相应孔后,拉杆弹簧11弹性拉伸 / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com