A high-speed train floor

A technology for high-speed trains and floors, which is applied to railway car bodies, railway car body components, instruments, etc., can solve problems such as the inability to meet the vibration and noise control requirements of high-speed trains, and achieve good vibration and noise reduction performance, long service life, and guaranteed The effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

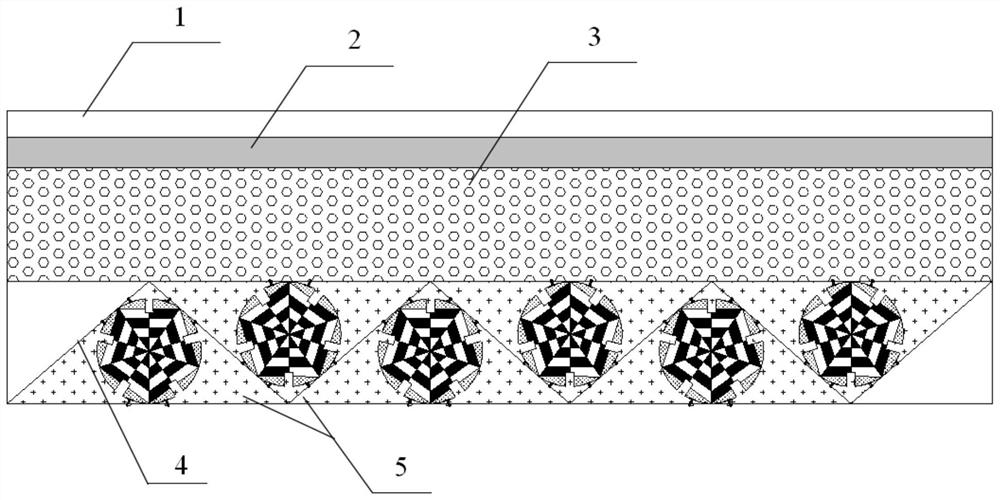

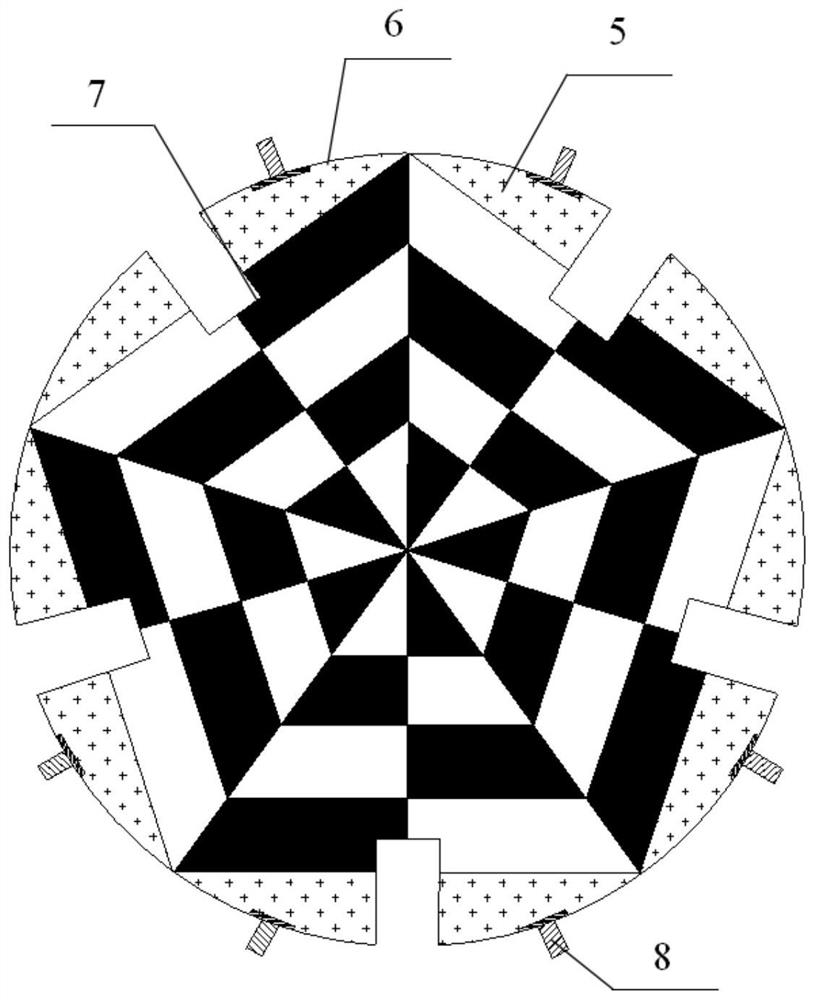

[0028] Such as figure 1 , 2 , shows the train floor of Embodiment 1 of the present invention, the train floor includes a car interior floor 1, thermal insulation material 2, porous sound-absorbing material 3, triangular aluminum frame layer, filling material 5, perforated metal cylinder 6 and three-dimensional standard Phononic crystal 7;

[0029] Among them, the interior floor 1, the thermal insulation material 2, the porous sound-absorbing material 3, and the triangular aluminum frame layer are arranged sequentially from top to bottom, wherein the triangular aluminum frame layer includes a plurality of triangular frames 4, and the cross section of each triangular aluminum frame 4 is In the shape of isosceles triangle, a phononic crystal structure composed of filling material 5, perforated metal cylinder 6 and three-dimensional quasi-phononic crystal 7 is placed in each of them, and arranged according to a certain period;

[0030] Preferably, the three-dimensional quasi-pho...

Embodiment 2

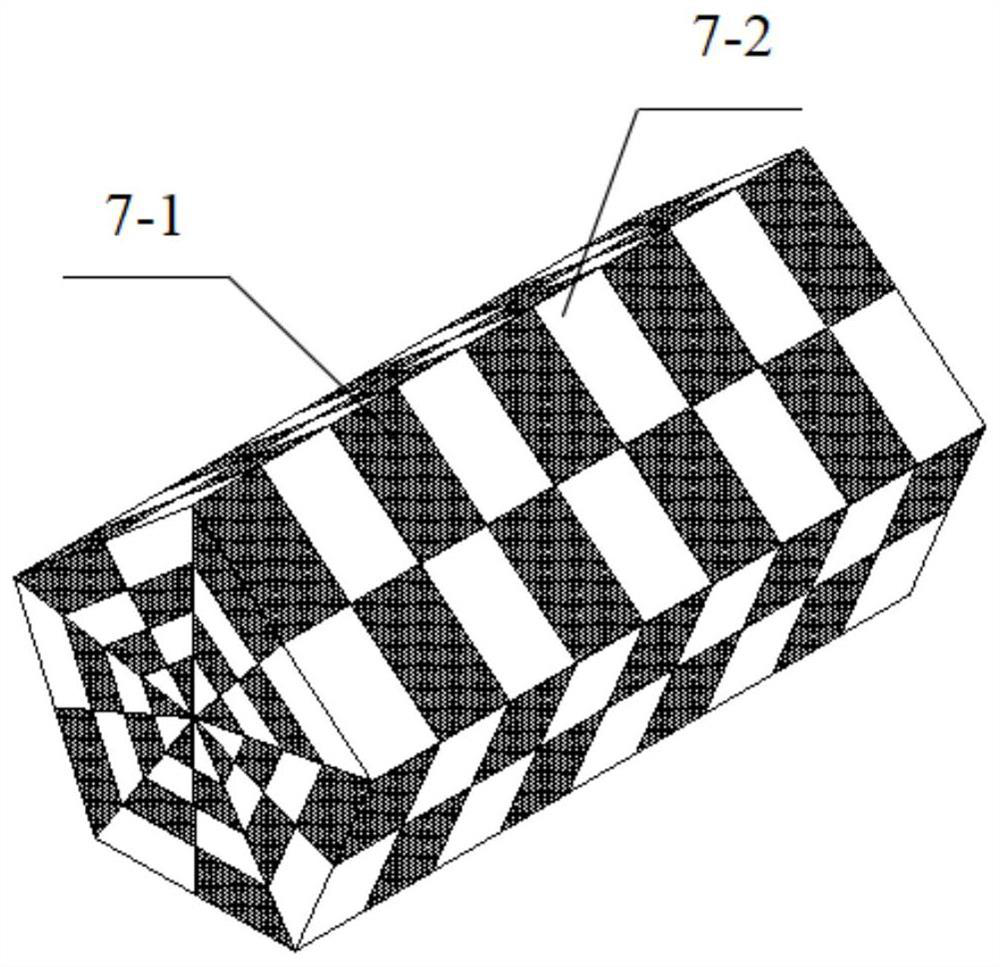

[0043] Embodiment 2: as Figures 1 to 3 As shown, in this embodiment, the arrangement of the first phononic crystal unit 7-1 and the second phononic crystal unit 7-2 is the same as in Embodiment 1; the difference between the two is that the first phononic crystal unit 7-1 and the structure of the second phononic crystal unit 7-2.

[0044] In this embodiment, the first phononic crystal unit 7-1 includes a piezoelectric ceramic core material and a pure copper metal film disposed on the surface of the piezoelectric ceramic core material; when the vibration wave propagates to the first phononic crystal unit 7-1 At this time, the piezoelectric ceramic core material will vibrate under the action of the vibration wave, and convert part of the vibration energy into electrical energy. The pure copper metal film can immediately convert the charge on the surface of the piezoelectric ceramic into heat energy through the resistance effect, thereby reducing Noise reduction effect. In orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com