Method for material warehousing verification, material picking and material packaging

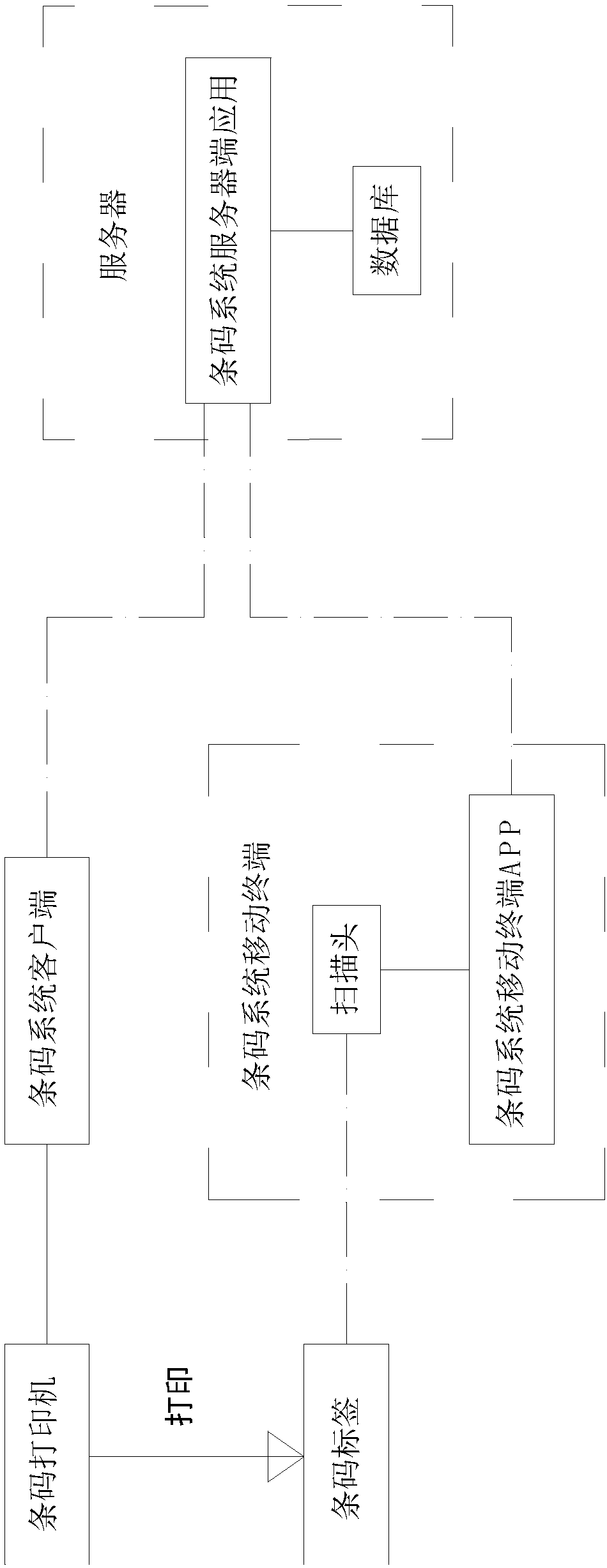

A calibration method and material technology, applied in logistics, instruments, data processing applications, etc., can solve the problems of modernization, intelligence, high labor costs, error-prone, etc., and achieve convenient and intelligent operation, convenient operation, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

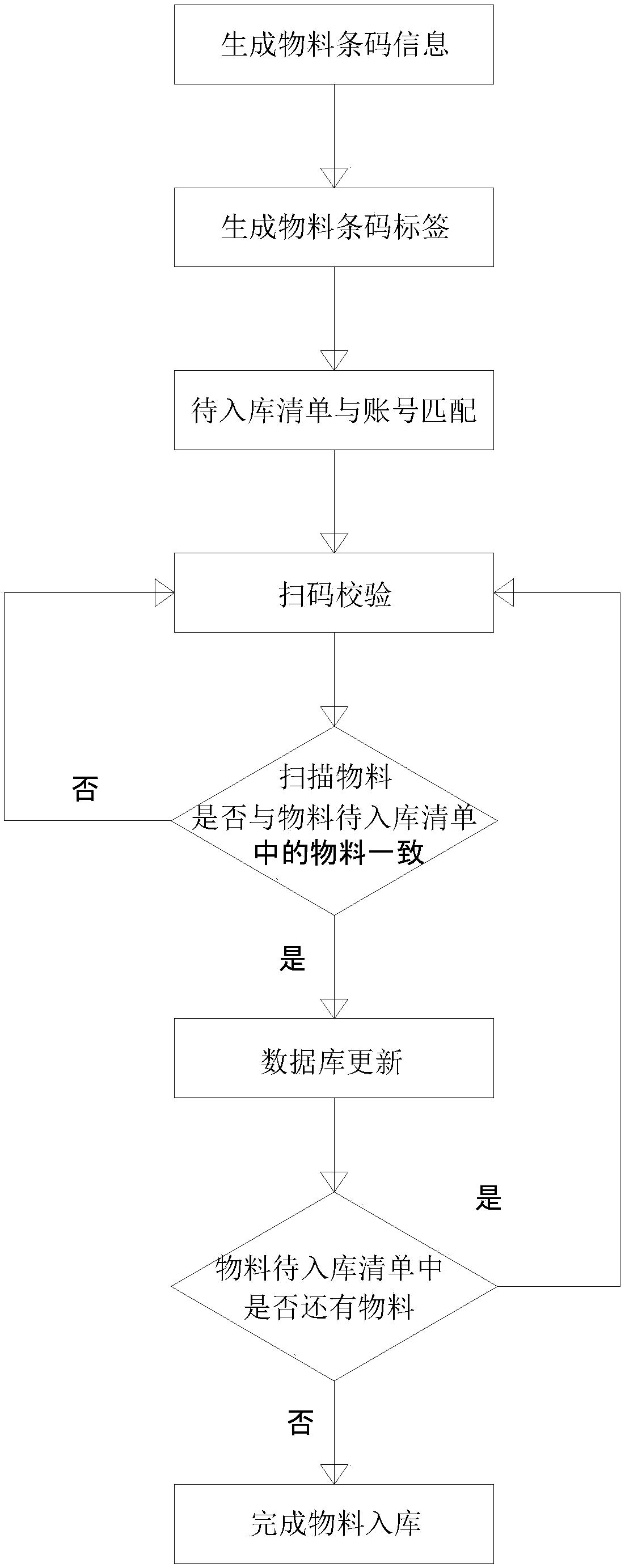

[0045] A method for verifying material storage, such as figure 2 As shown, the method includes the following steps:

[0046] S1: Generate material barcode information: when receiving goods, the barcode system client retrieves the corresponding goods receipt from the server, and the server generates material barcode information based on the material information on the retrieved goods receipt, and adds the material barcode information to The waiting list of the storage warehouse corresponding to the material is fed back to the barcode system client, and the barcode information of the material includes the storage information of the material;

[0047] S2: Generate material barcode labels: the barcode system client sends the material barcode information fed back by S1 to the connected barcode printer for printing, generates material barcode labels with material barcodes, and pastes the labels on the corresponding materials, and then passes The mobile terminal of the barcode syst...

Embodiment 2

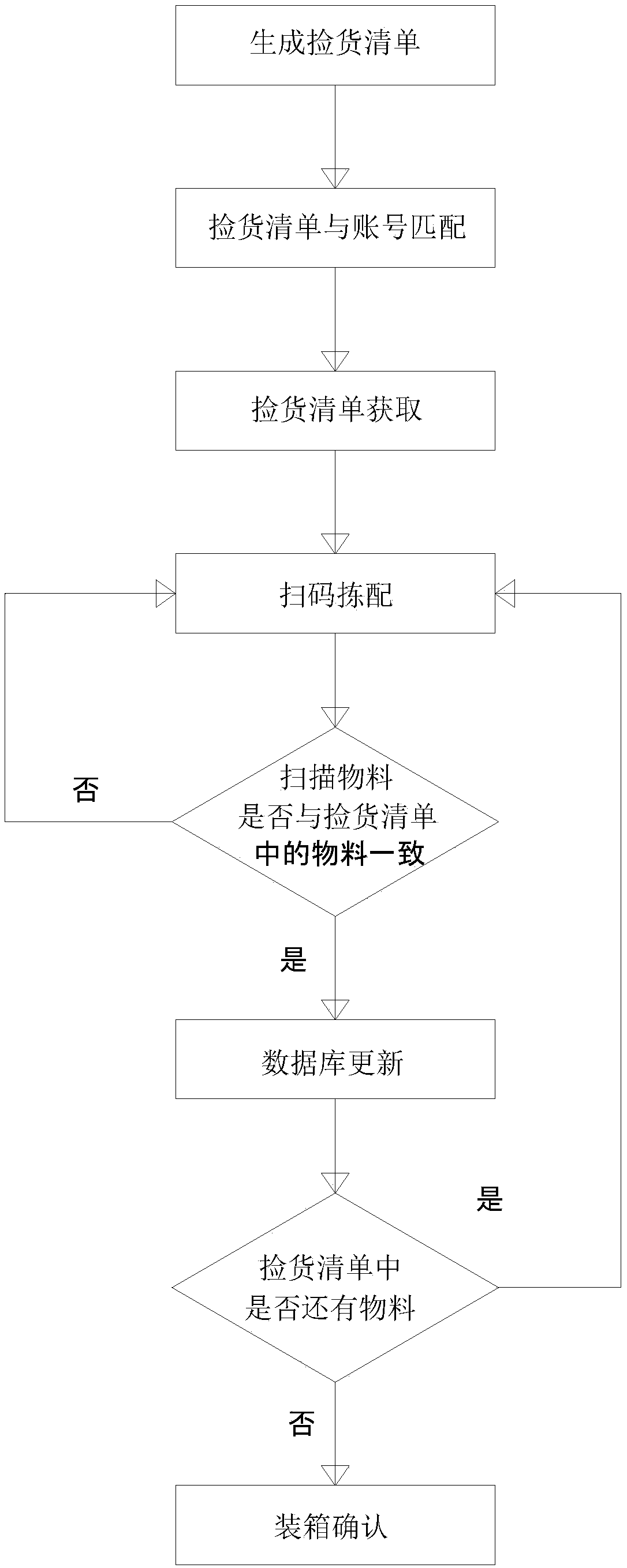

[0055] A material picking method based on the material warehousing verification method of Embodiment 1, such as image 3 As shown, the method includes the following steps:

[0056] S1: Generate a pick-up list: the sales merchandiser creates a sales order and sends it to the server. After the server receives the sales order information, it imports the sales order information into the built-in barcode system in the server. The bill is divided into different picking lists according to the different warehouses where the materials are stored. The picking list includes customer information, a list of materials to be picked and warehouse information, and the list of materials to be picked includes material barcode information of several materials to be picked;

[0057] S2: Match the picking list with the account: the server matches the generated picking list to the corresponding barcode system account;

[0058] S3: Obtaining the picking list: the mobile terminal of the barcode syste...

Embodiment 3

[0065] A material packing method according to the material picking method of Embodiment 2, such as Figure 4 As shown, the method includes the following steps:

[0066] S1: Generate packing code: Generate box information in the built-in database of the server, the box information includes the packing code set on the box; print the packing code label through the barcode printer connected to the barcode system client, and Set the packing code label on the box body;

[0067] S2: Generate a packing plan: the server retrieves the order information and generates a packing plan according to the order information. The packing plan is divided into different packing lists according to different warehouses where the materials are stored, and the packing list includes customer information , the list of materials to be loaded and warehouse information, the list of materials to be loaded includes the material barcode information of several materials to be loaded;

[0068] S3: Packing list...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com