Material demand scheme design method and system for equipment manufacturing industry

A technology of material requirements and scheme design, applied in manufacturing computing systems, logistics, computing, etc., can solve problems such as difficult to control the production cost of production resources and products, and difficult to solve coordination problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

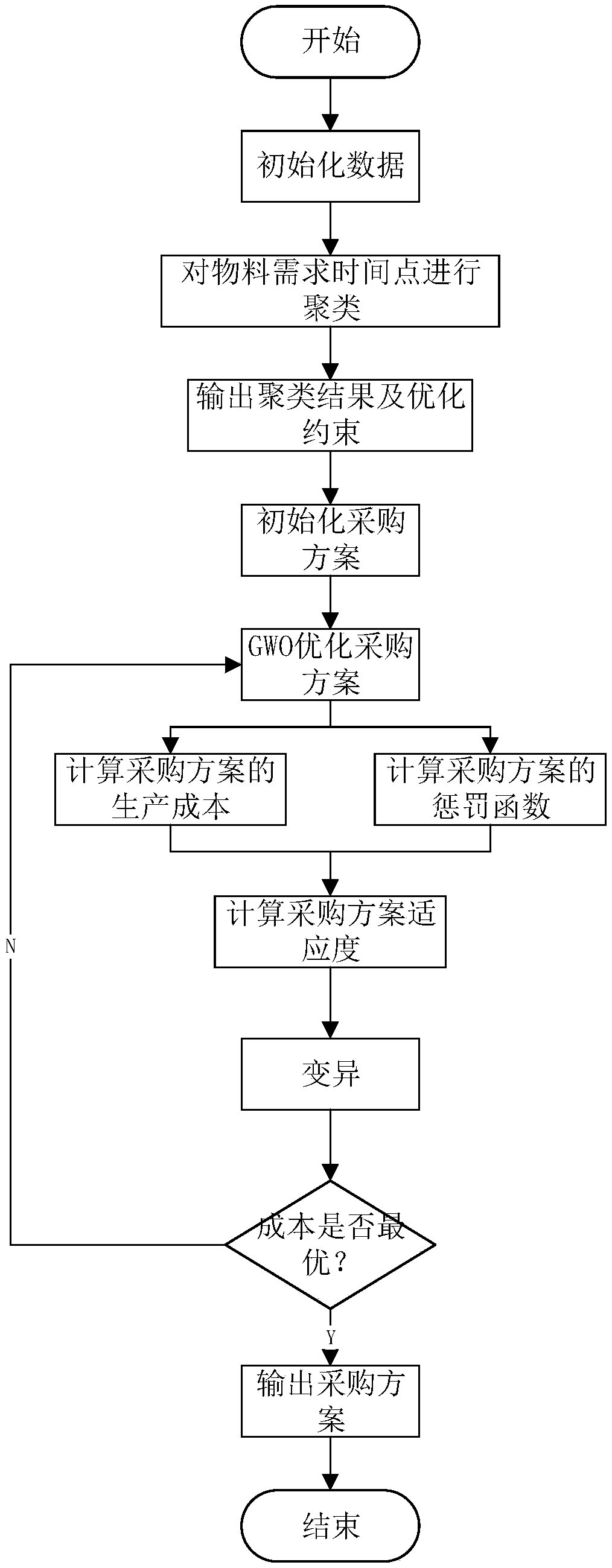

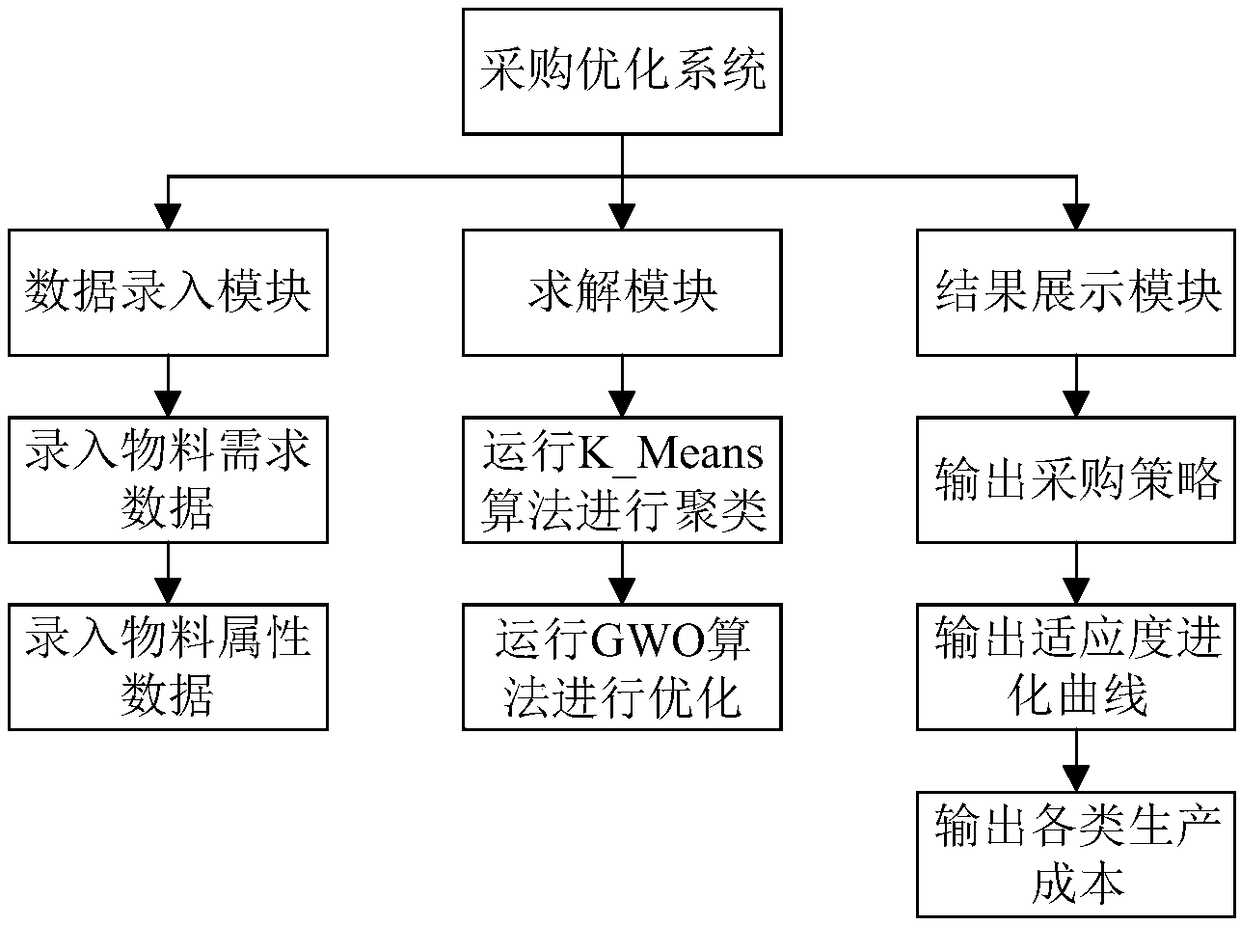

[0066] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

[0067] 1. Description of material procurement problems

[0068] Initialize the enterprise material demand data set Mn and the material property data set Mps. Obtain the demand time point set T={T from the material demand data set Mn i |i=1,2,...,n}, the demand quantity of each material at each demand time point Mq={Mq ij |i=1,2,···,n; j=1,2,···,h}; obtain the material set M from the material attribute set Mp={M i |i=1,2,···,h}, the purchase price of each material Mp={M Pi |i=1,2,···,h}, the inventory management cost of each material per unit time unit quantity Rm={Rm i |i=1,2,...,h}. In consideration of the production cost of the enterprise and the satisfaction of production, it is necessary to purchase all kinds of materials required within the time period of material demand. In order to achieve centralized procurement, it is necessary to combi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com