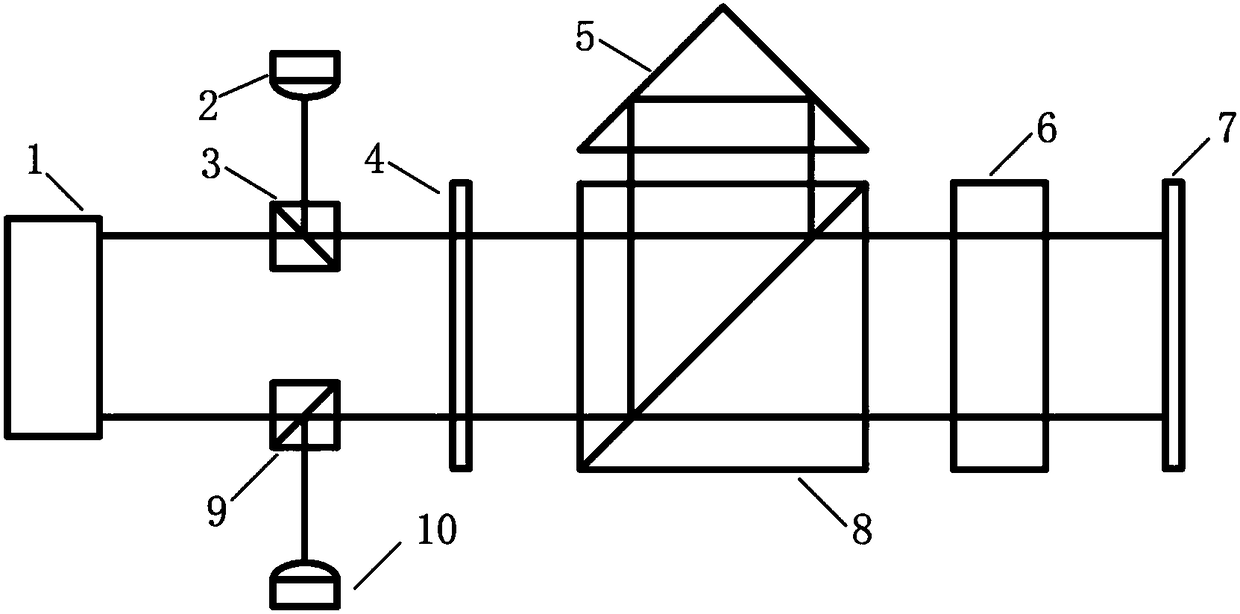

Laser-heterodyne-interference measuring device and method based on plane mirror reflection

A technology of laser heterodyne interference and measuring device, which is applied to measuring device, adopts optical device, interferometer, etc., can solve the problems of optical thermal drift and complicated optical path structure, and achieves the suppression of optical nonlinear error, simple optical path structure, and difficult optical path structure. Effects of Optical Thermal Drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1: Measuring the displacement of the linear guide stage

[0042] (1) Fix the plane mirror on the stage of the linear guide rail, and move with the linear guide rail;

[0043] (2) set up the interferometric optical path of the present invention, select the right-angle reflector and the optical compensation mirror with the same material and refractive index n, if the optical path of the reference beam in the right-angle reflector is L, then the optical compensation mirror along The thickness measured in the direction of the beam is

[0044] (3) Adjust the direction of the two outgoing lights of the laser so that the direction is parallel to the movement direction of the stage;

[0045] (4) Adjust the angle of the measured plane mirror so that the measuring beam is vertically incident on the measured plane mirror;

[0046] (5) adjust the angle of the third polarization beam splitter and the right-angle mirror, so that the reference beam incident on the photoele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com