Mobile filter cloth drying device

A kind of drying equipment and mobile technology, applied in the field of mobile filter cloth drying equipment, can solve the problems of environmental damage, affecting the working environment of workers, consuming a lot of time and energy, and achieving the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

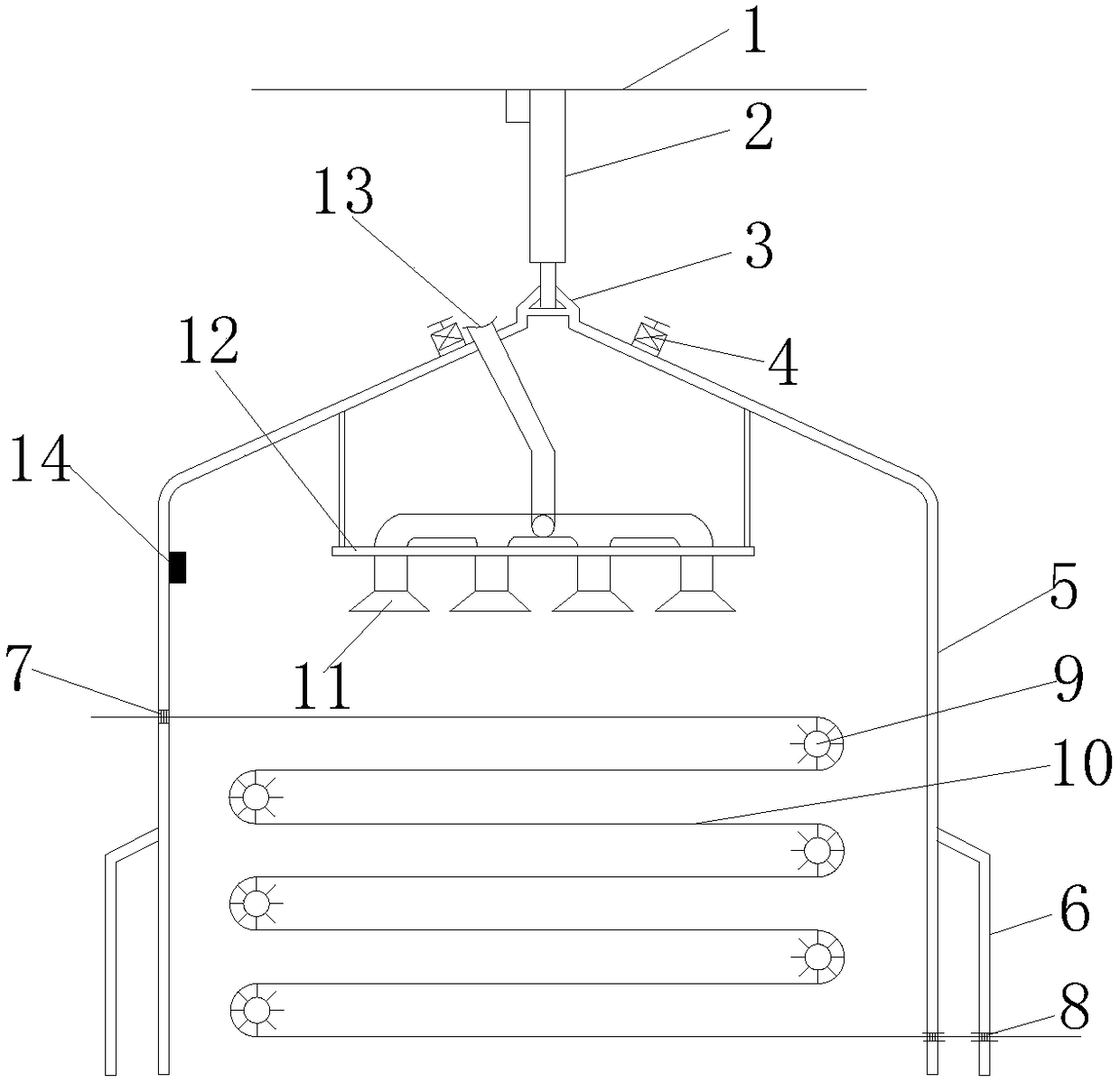

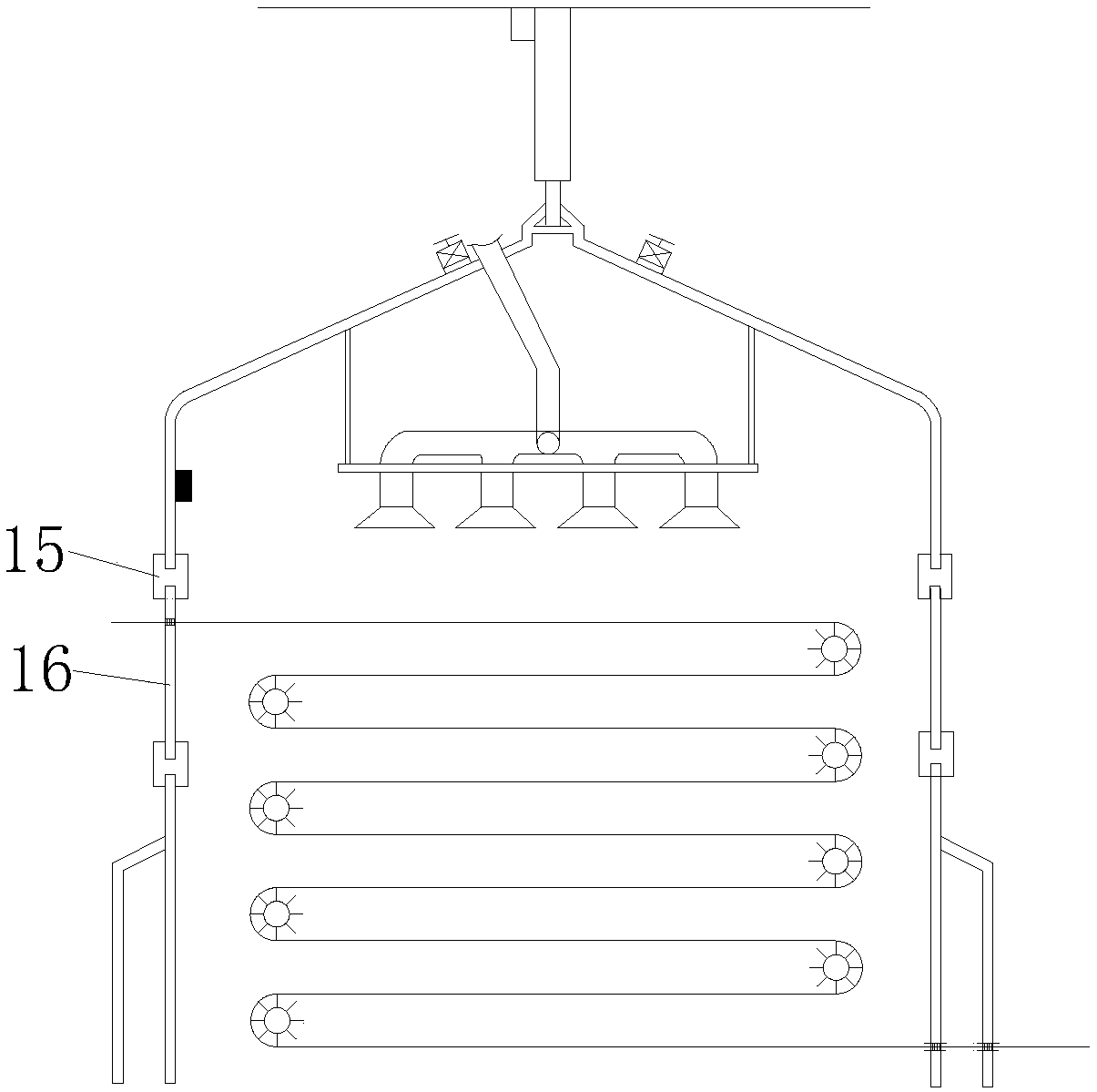

[0032] A mobile filter cloth drying device of the present invention comprises: a cover shell 5, the cover shell 5 is a semi-closed structure with a lower opening, and a heating device is arranged on the inner wall of the cover shell 5;

[0033] The electric carriage 1 is arranged on the top of the housing 5, the electric carriage 1 is connected to the top of the housing 5 through the first lifting unit 2, and the first lifting unit 2 is used to drive the entire housing 5 along the vertical direction. Move up and down in direction;

[0034] A filter cloth inlet 7 and a filter cloth outlet 8 are respectively arranged on the opposite ends of the cover shell 5, the filter cloth inlet 7 and the filter cloth outlet 8 are both arranged horizontally, and the width of the filter cloth inlet 7 is the same as the width of the filter cloth outlet 8 Both are adapted to the width of the filter cloth 10, the filter cloth 10 enters the inside of the cover shell 5 through the filter cloth inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com