A filter bag pinhole gluing device and gluing method thereof

A glue coating device and filter bag technology, which is applied to the surface coating liquid device, coating, pretreatment surface, etc., can solve the problems of uneven glue edge, unsightly appearance, and difficulty in accuracy, and achieve the glue edge Neat and beautiful, accurate gluing position, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

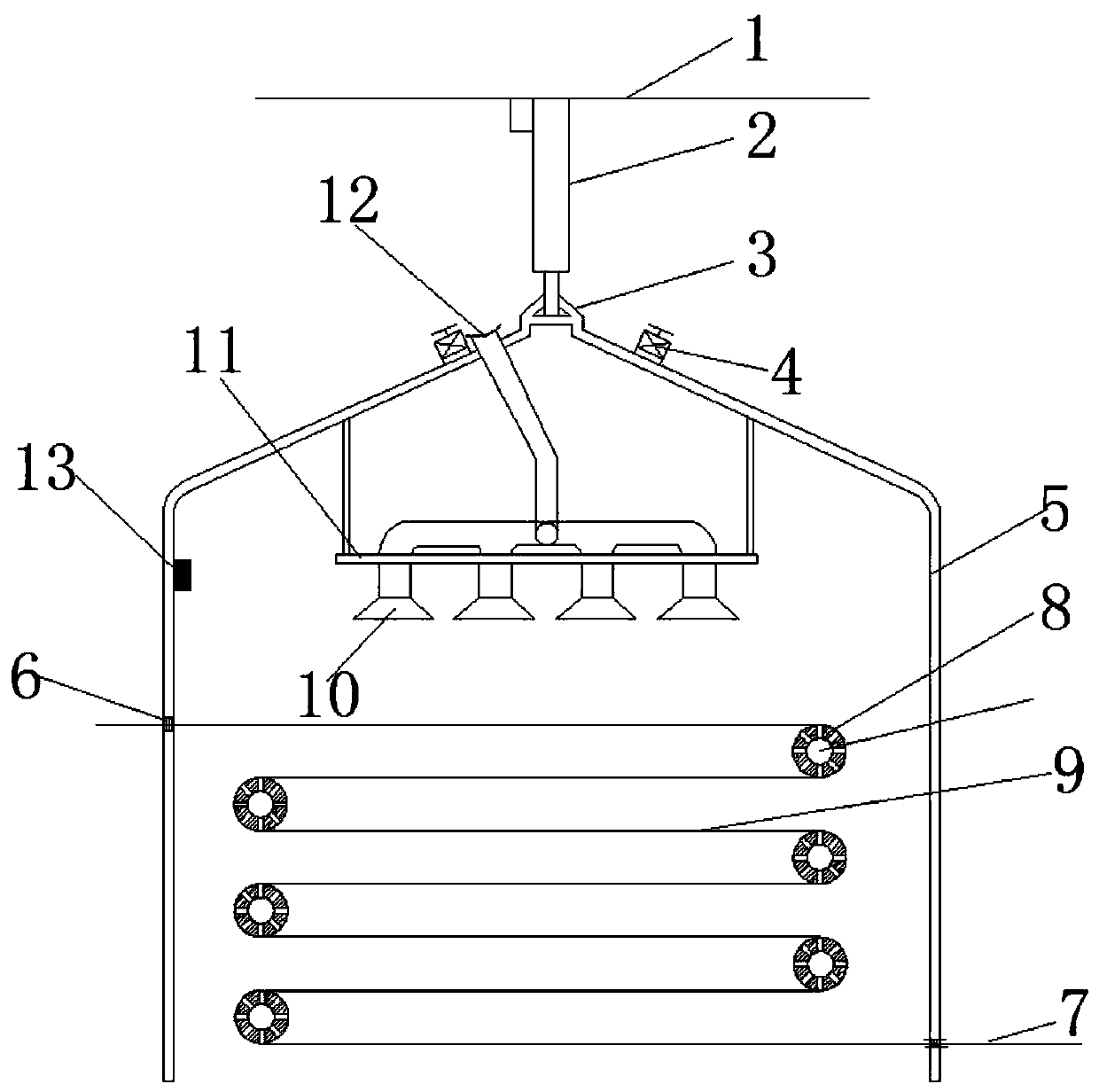

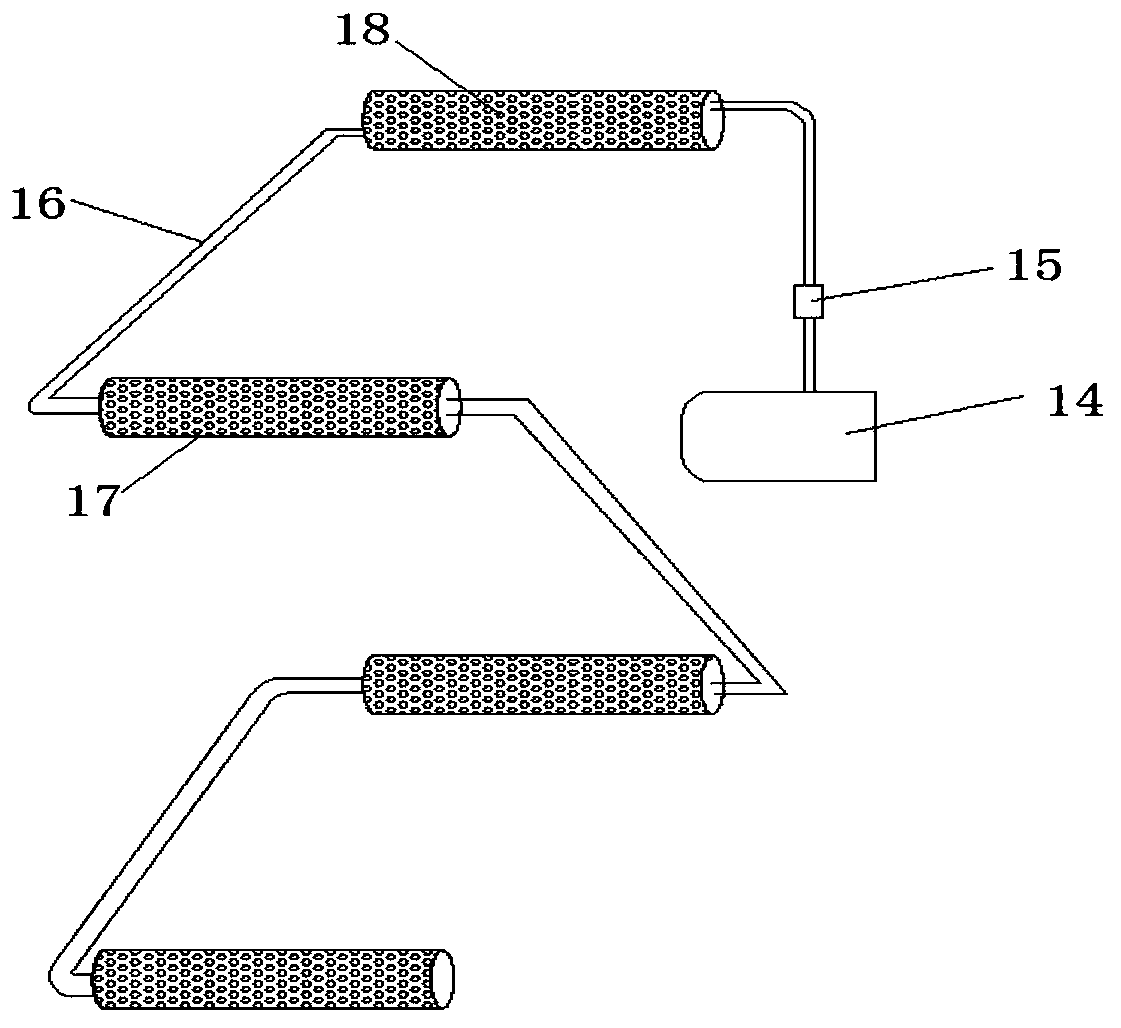

[0052] A filter bag pinhole gluing device of the present invention comprises: a cover shell 5, the cover shell 5 is a semi-closed structure with a lower opening, and a heating device is arranged on the inner wall of the cover shell 5; an electric carriage 1. Set above the cover body 5, the electric carriage 1 is connected to the top of the cover body 5 through the lifting unit 2, and the lifting unit 2 is used to drive the entire cover body 5 to move up and down in the vertical direction ; The filter bag inlet 6 and the filter bag outlet 7 are respectively arranged on the two opposite ends of the cover shell 5, the filter bag inlet 6 and the filter bag outlet 7 are all horizontally arranged, and the width of the filter bag inlet 6 is the same as that of the filter bag outlet 7 The width is adapted to the width of the filter bag 9; 6 electric control rollers are arranged in the cover body, and each electric control roller is arranged alternately in parallel with each other in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com