A kind of automatic filter cloth cleaning method

A filter cloth and cleaning tank technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of time-consuming and laborious, many manual operations, and low cleaning efficiency, so as to improve the working environment, avoid frontal contact, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

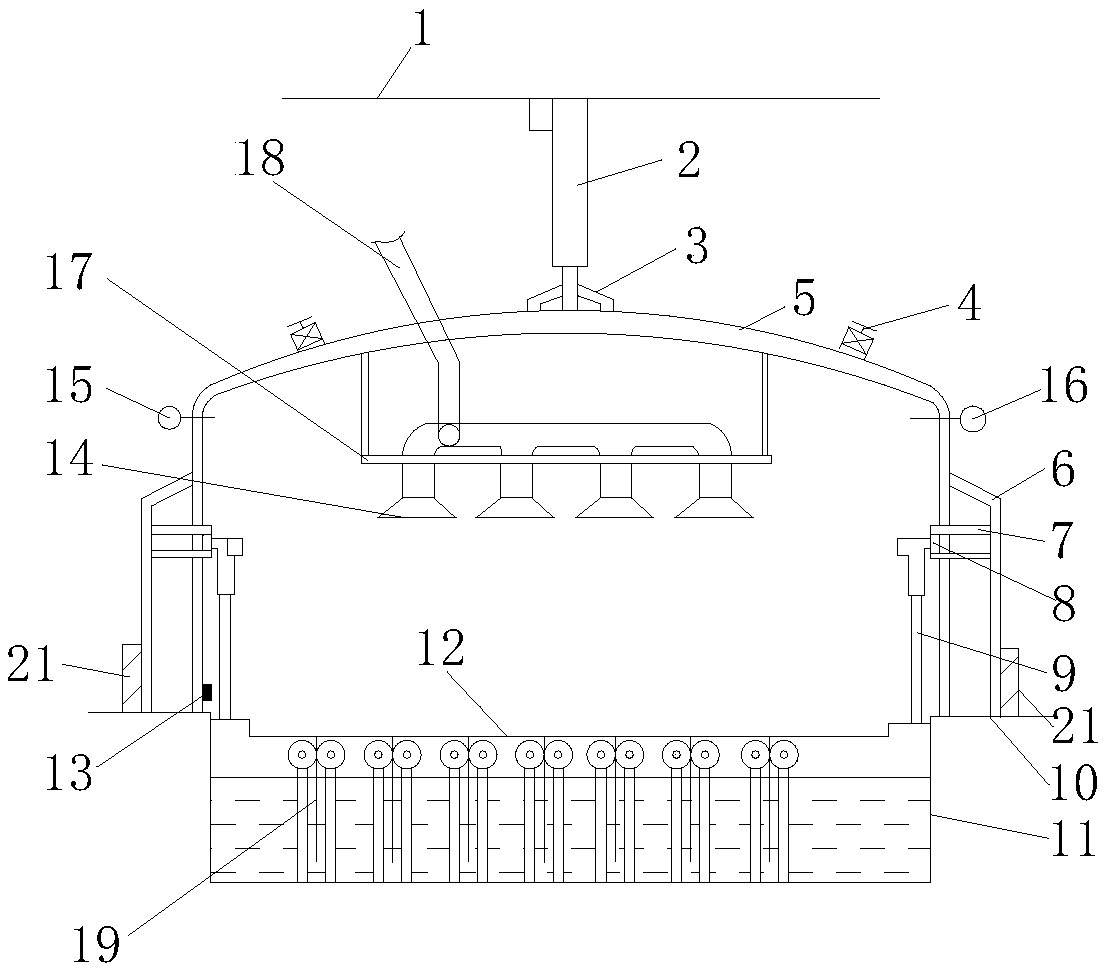

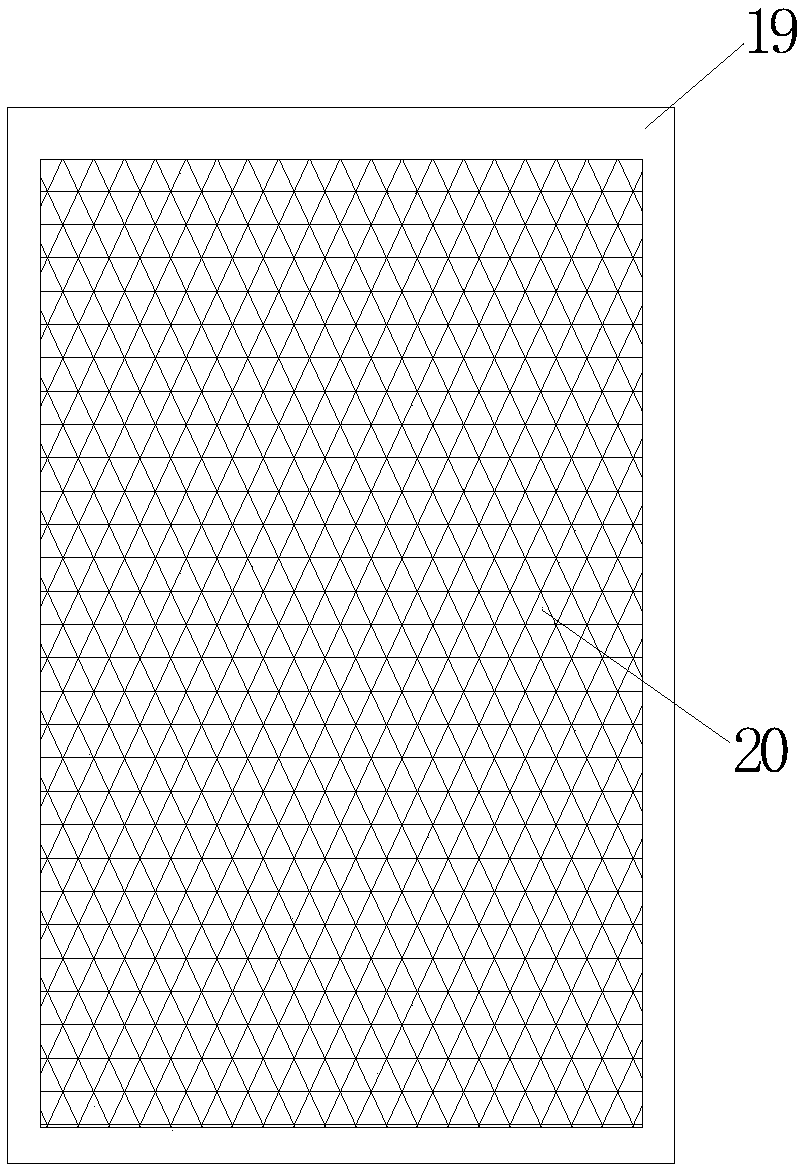

[0037] An automatic filter cloth cleaning method of the present invention is based on a set of cleaning device, and the device includes: a cleaning tank 11 for containing cleaning liquid, in the cleaning tank, a number of cleaning roller groups 21 are evenly spaced along the length direction of the cleaning tank; a cover shell 5. Set above the cleaning pool 11, used to cover and seal the cleaning pool 11, the electric carriage 1 is set above the cover body 5, and the electric carriage 1 is connected to the cover through the first lifting unit 2 On the top of the housing 5, the first lifting unit 2 is used to drive the entire cover housing 5 to move up and down in the vertical direction; the bottom of the cover housing 5 is connected with a filter cloth fixing frame 12 through the second lifting unit 9, the The filter cloth fixing frame 12 includes a connecting frame and several filter cloth fixing frames 19 arranged on the connecting frame along the length direction of the clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com