Centralized lubrication cooling and cleaning system and tractor

A centralized lubrication and cleaning technology, applied in gear lubrication/cooling, mechanical equipment, transmission parts, etc., to achieve the effect of prolonging the service life, reducing the cost of use, and convenient maintenance and inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

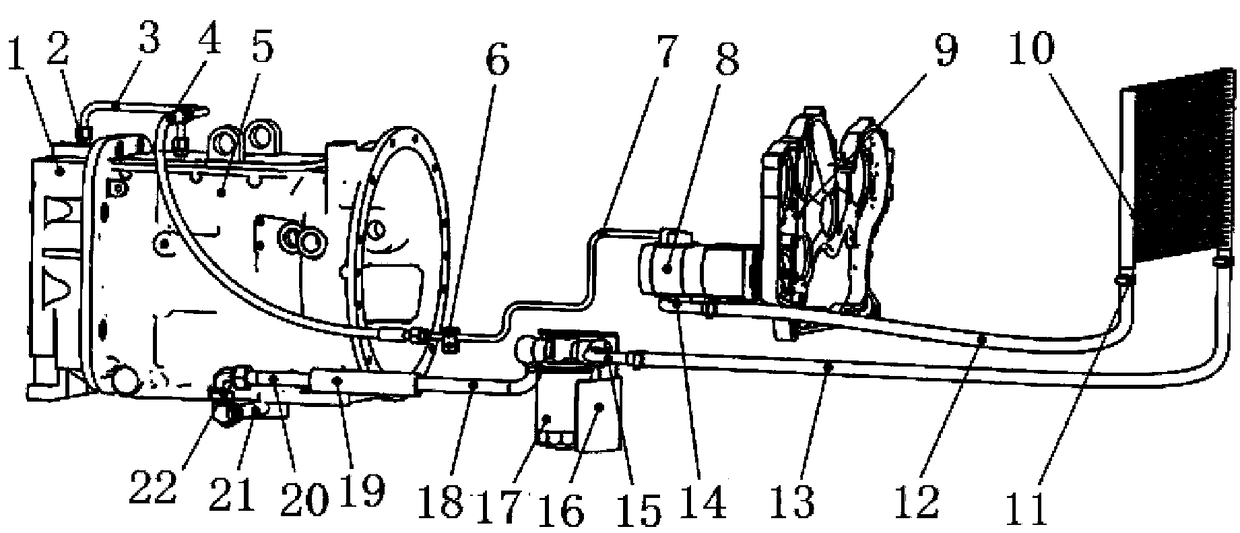

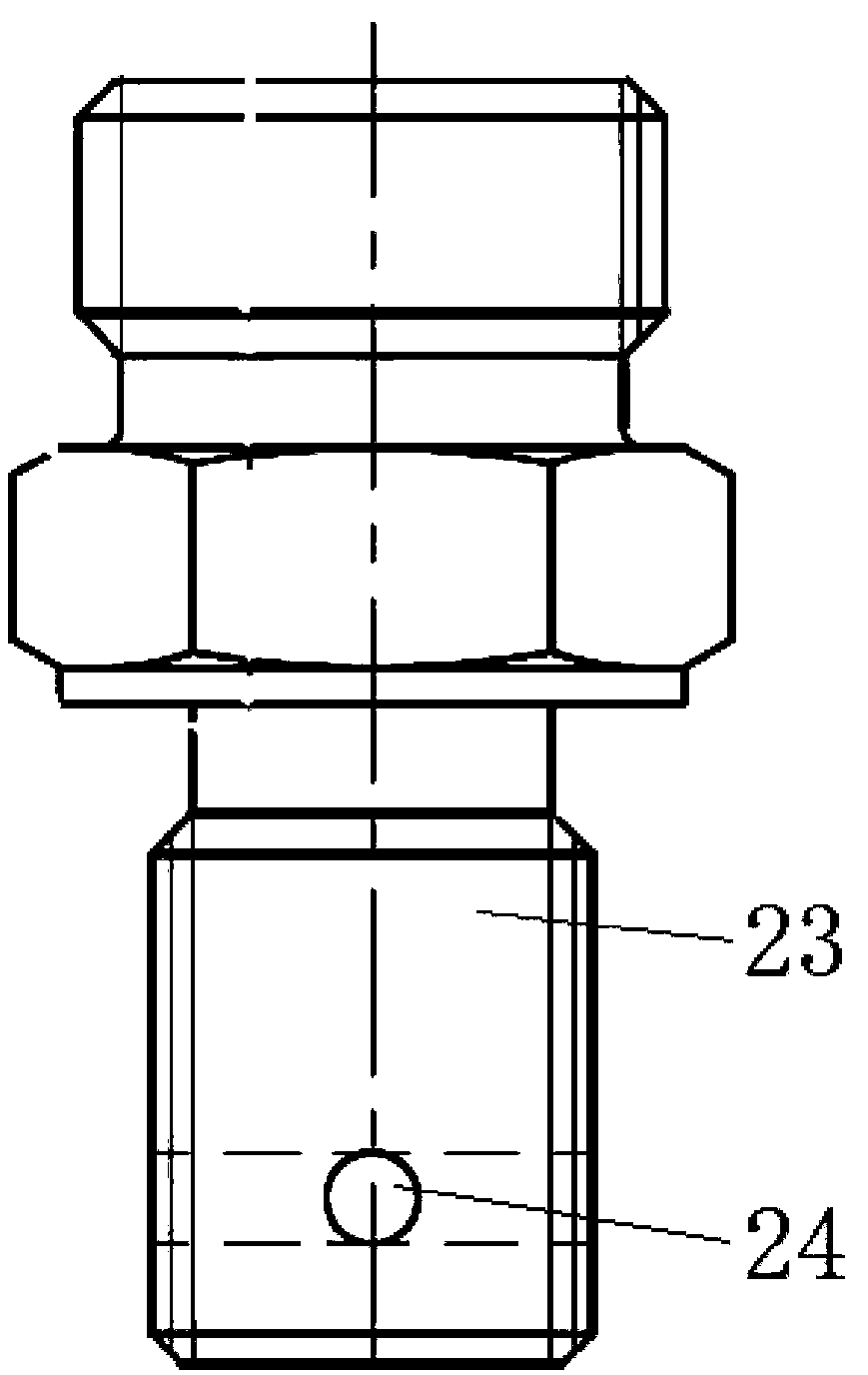

[0023] like figure 1 and figure 2 As shown, the present invention provides a centralized lubricating and cooling cleaning system, including a gearbox 5, an oil filter 17, an oil cooler 10 and a lubricating pump 8; the oil filter 17 is connected to the bottom of the gearbox 5 through an oil filter inlet pipe, so that The lubricating oil collected at the bottom of the gearbox 5 can be sent to the oil filter 17 through the oil filter inlet pipe; the oil filter 17 is connected to the oil cooler 10 through the oil cooler oil inlet pipe, so that the filtered lubricating oil can enter the oil cooler The oil cooler 10 is connected to the lubricating pump 8 through the oil outlet pipe of the oil cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com