Transmission system capable of achieving three variable transmission processes

A technology of transmission system and driven gear, applied in transmission device, fluid transmission device, belt/chain/gear, etc., can solve the problem of low transmission efficiency and achieve the effect of expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

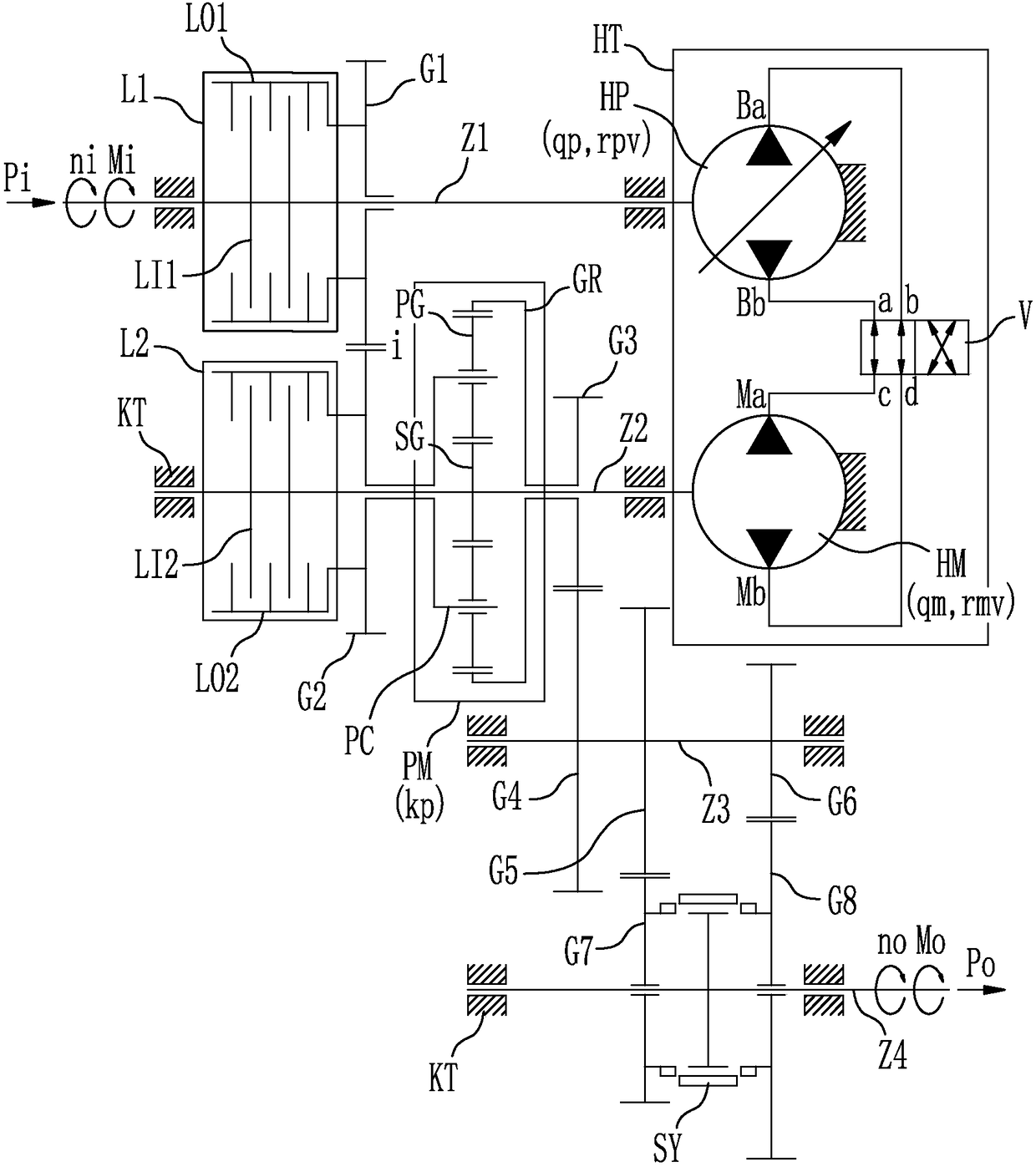

[0045] Embodiment: a kind of transmission system that can realize three kinds of variable speed transmission processes

[0046] see figure 1 As shown, the transmission system consists of gear shaft transmission components, a shift synchronizer SY, a first clutch L1, a second clutch L2, an NGW type planetary gear mechanism PM, a hydraulic transmission module HT and a transmission system housing KT constitute.

[0047] Gear shaft transmission parts include input shaft Z1, sun gear shaft Z2, intermediate shaft Z3, output shaft Z4, input gear G1, linkage gear G2, intermediate driving gear G3, intermediate driven gear G4, high gear driving gear G5, low gear The driving gear G6, the high gear driven gear G7 and the low gear driven gear G8, wherein: the input shaft Z1, the sun gear shaft Z2, the intermediate shaft Z3, and the output shaft Z4 are arranged in parallel and are rotatably supported relative to the system housing KT. The input gear G1 is in constant mesh with the linkage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com