A monitoring method of hydraulic system in fully mechanized mining face

A technology of fully mechanized mining face and hydraulic system, applied in the field of hydraulic system monitoring of fully mechanized mining face, can solve the problems of lack of hydraulic system monitoring of working face, etc., and achieve the effect of convenient control and wide monitoring range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0029] The method for monitoring the hydraulic system of the fully mechanized mining face of the present invention collects the liquid supply volume of the hydraulic support, and collects the outlet pressure of the pump station, the inlet and outlet pressure of the inlet and filter station, the pressure of the inlet pipeline, the pressure of the column, the pressure of the side protection, and the return pipeline Pressure and pressure at the inlet and outlet of the liquid return filter station; the above-mentioned collected information is transmitted to the monitoring host of the working face, and the monitoring host of the working face displays the received information, and the staff make corresponding adjustments and investigations according to the displayed information.

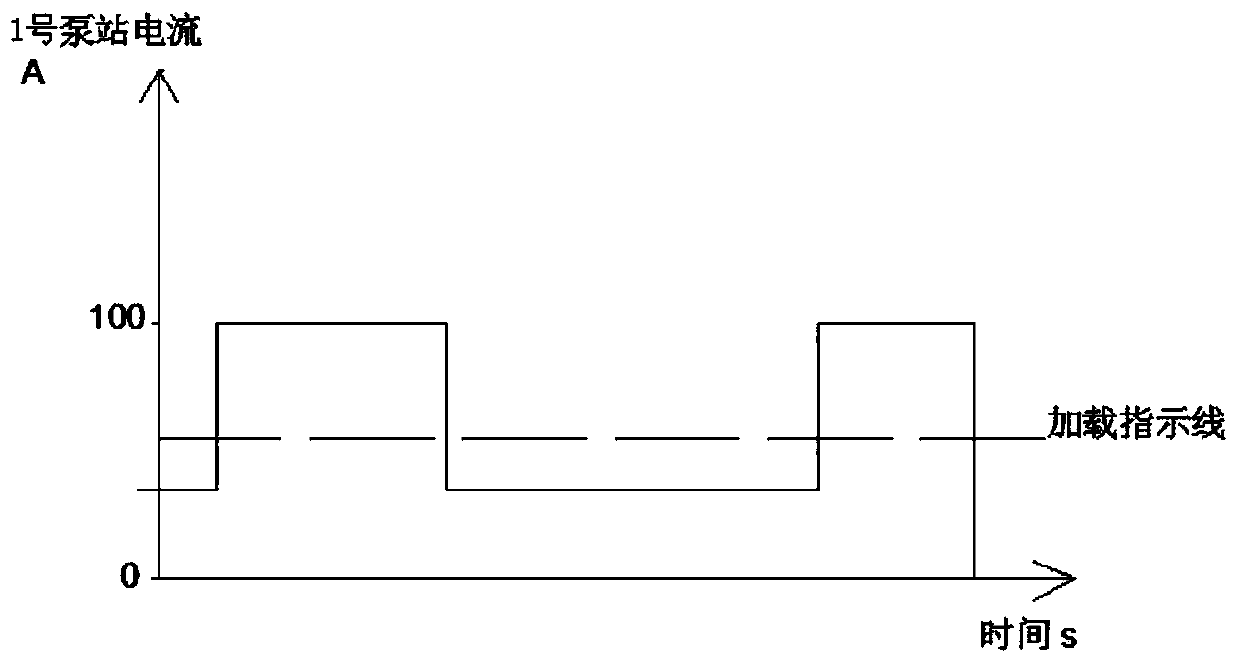

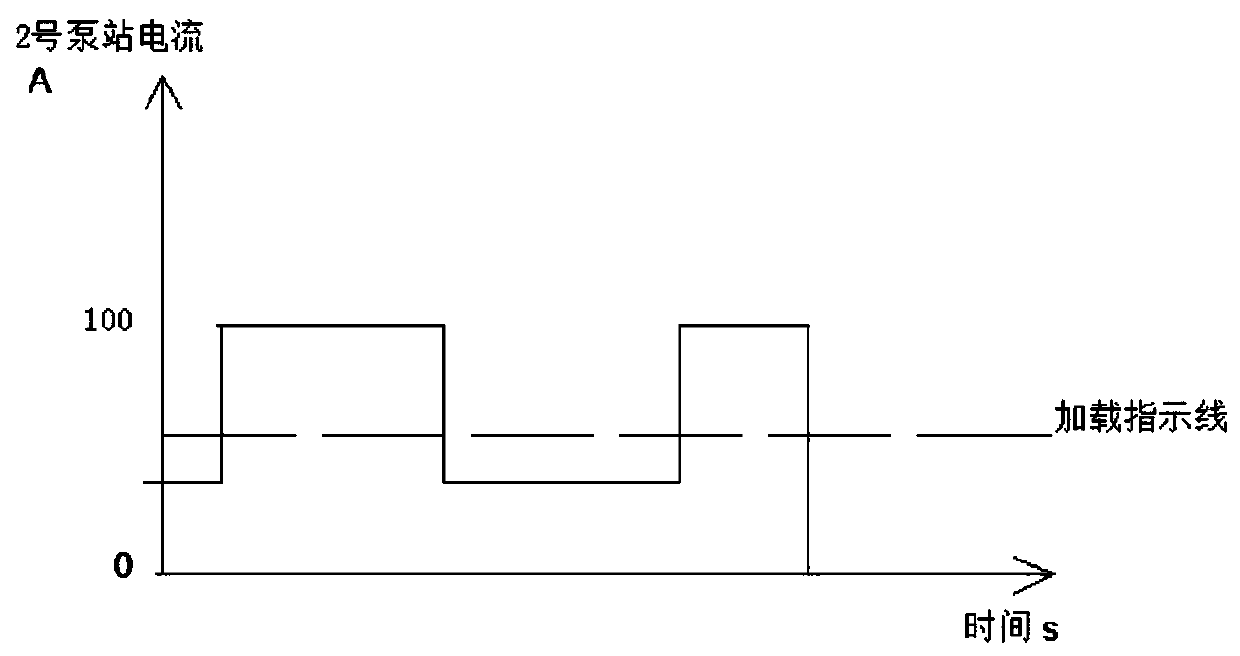

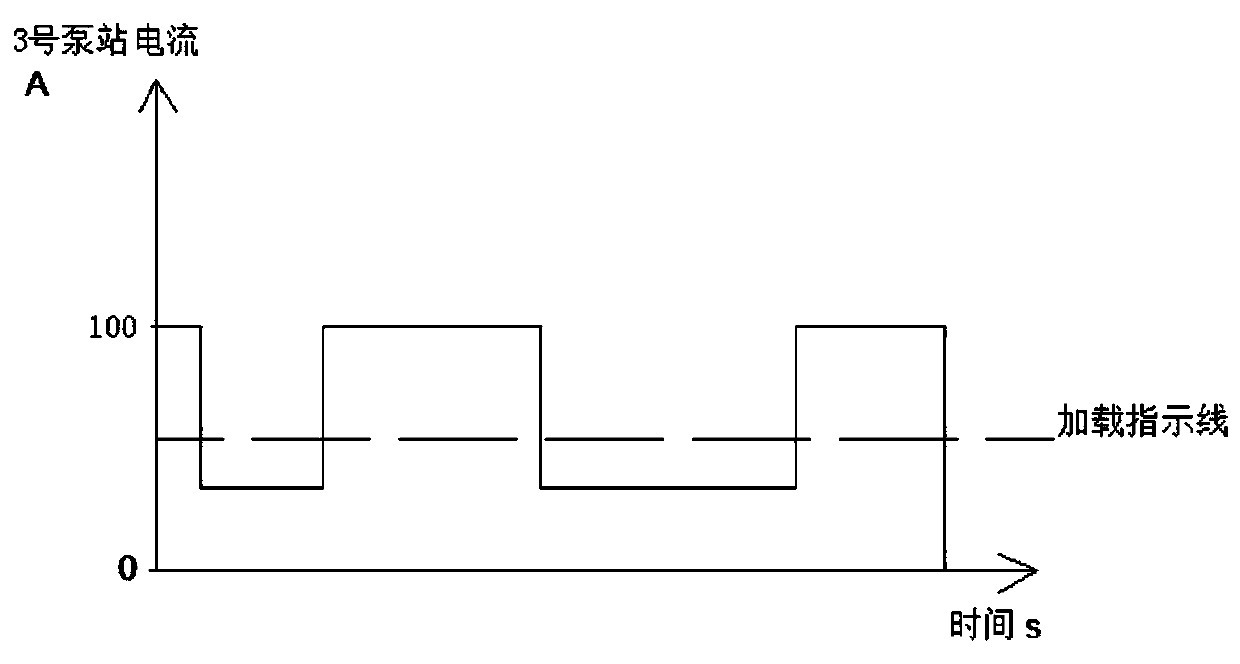

[0030] The first m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com