A four-angle steel fully assembled anti-buckling bracing that can directly replace the cross-shaped core

A buckling-resistant support, cross-shaped technology, applied in the direction of earthquake resistance, building types, protected buildings/shelters, etc., to achieve the effects of optimizing post-earthquake repair work, ingenious force bearing, and improving efficacy and timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

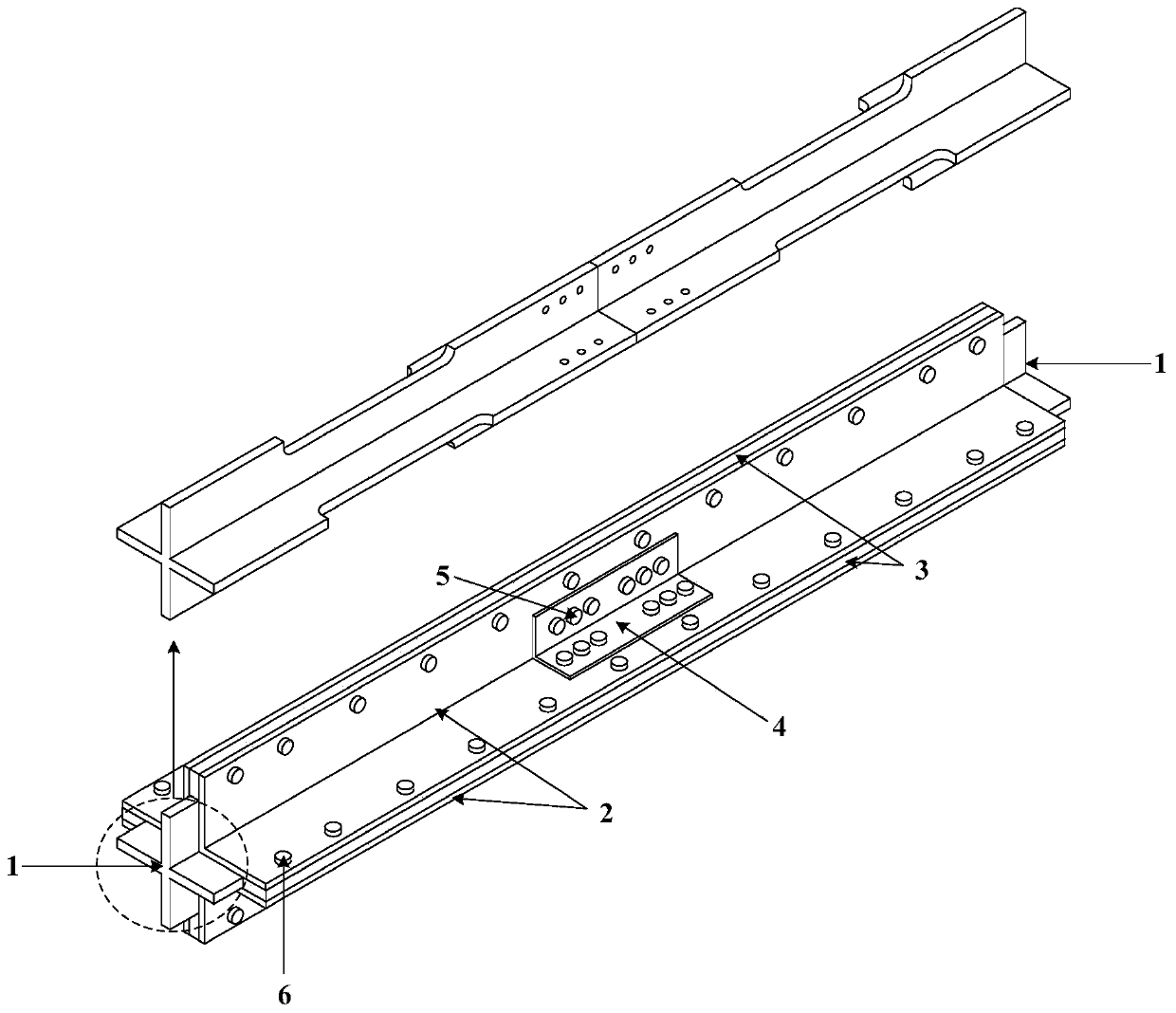

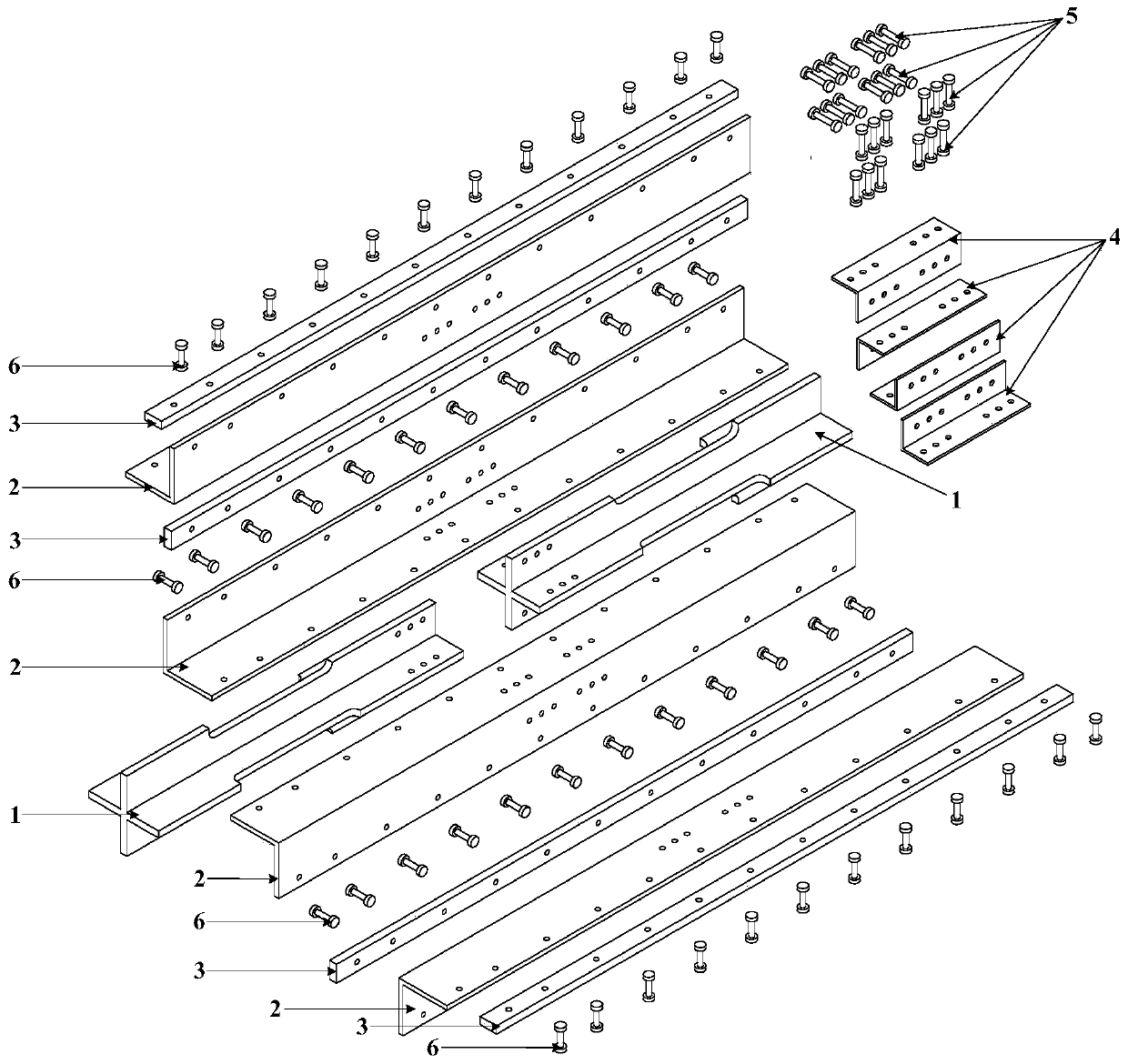

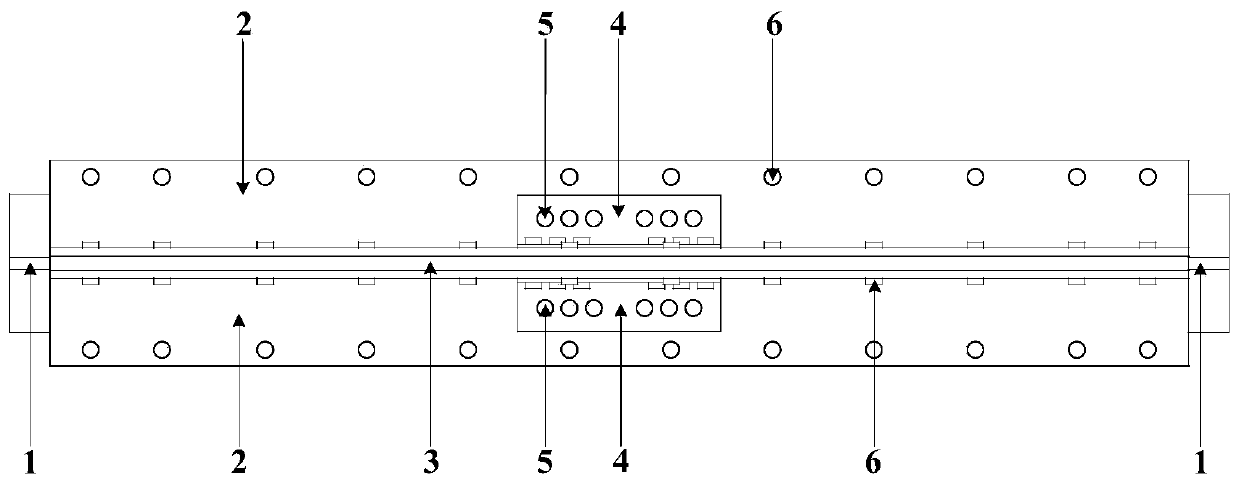

[0026] Attached below Figure 1-8 , detailing the implementation of this patent.

[0027] Such as Figure 1-8 As shown, a four-angle steel fully assembled anti-buckling support that can directly replace the cross-shaped core includes the following components:

[0028] 1——cruciform core component;

[0029] 2——four angle steel restraint members;

[0030] 3 - backing plate;

[0031] 4——L-shaped connector outside the inner core;

[0032] 5——The first high-strength bolt group;

[0033] 6——The second high-strength bolt group;

[0034] 7—End reinforcement area;

[0035] 8 - central weakened area;

[0036] 9——The opening connection area at the end;

[0037] 10 - weakened dog bone;

[0038] 11——Slot weakening;

[0039] 12——Rubber material filling.

[0040] Such as Figure 1-8 As shown, a fully assembled anti-buckling brace with four-angle steel that can directly replace the cross-shaped inner core, including two cross-shaped inner core members (1), four angle steel restraint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com