Energy-saving fireproof foam ceramic glazed exterior wall panels

A foamed ceramic and exterior wall panel technology, which is applied in ceramic products, other household appliances, household appliances, etc., to achieve the effect of good overall performance, good protection performance and small thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

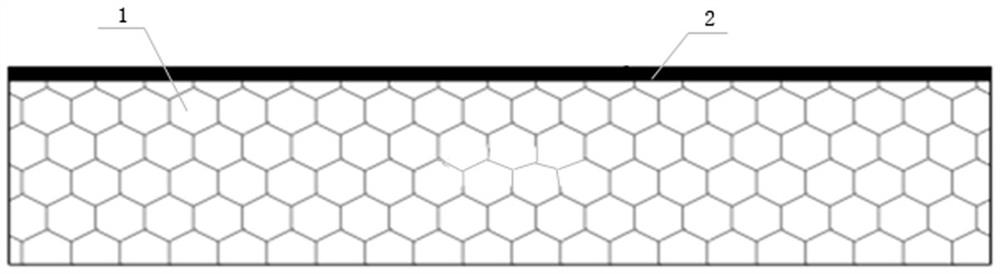

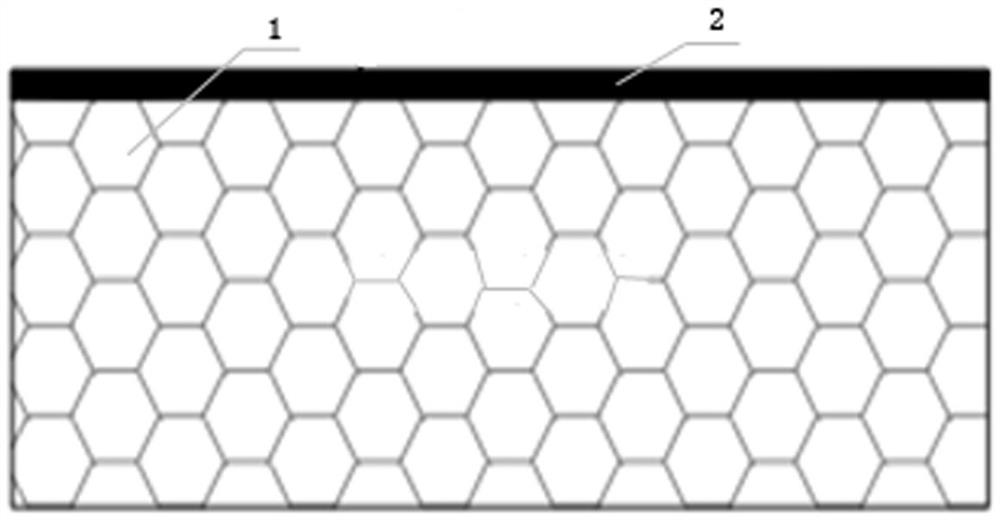

[0031] Energy-saving firefoam ceramic glaze outer wall plate, including the foam ceramic layer 1 is a glaze layer 2 on the foam ceramic layer 1, and the preparation method thereof includes the following steps:

[0032] (1) Foam ceramic raw powder and formulated nano-nano glaze containing nano-zinc oxide into the bunless material;

[0033] (2) Aluminum silicate isolation paper is paved at the bottom of the burning kiln;

[0034] (3) Nano-new glaze that is 1 cm in the first floor of the first floor of the baffled kiln.

[0035] (4) On this basis, add 1 cm excessive powder, excessive powder consisting of coal gangue, ceramic tailings, waste porcelain and tail tailings;

[0036] (5) Repatrign the foam ceramic powder powder, enter the kiln to firing;

[0037] (6) After 1,200 ° C, after cutting, after cleaning the glaze or polished, forming a foam ceramic glazed outer wall panel finished product, after inspection.

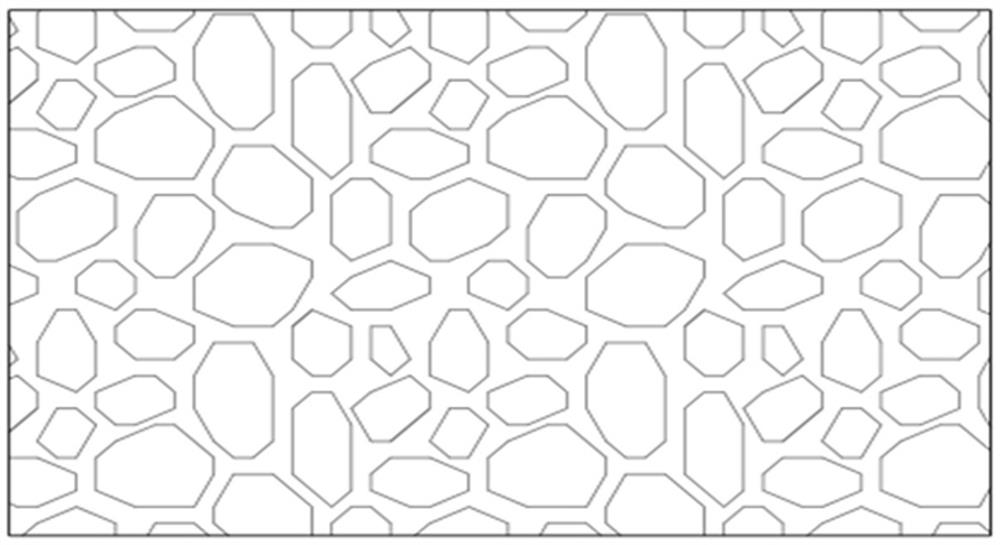

[0038] Foam ceramic original powder component and its chemical composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| barrier rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com