Cement retarder and its preparation method and application

A cement retarder and cement technology, which is applied in the field of building materials, can solve the problems of not being able to adjust the setting time and not being able to use cement retarders, and achieve the effects of low cost, increased strength, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

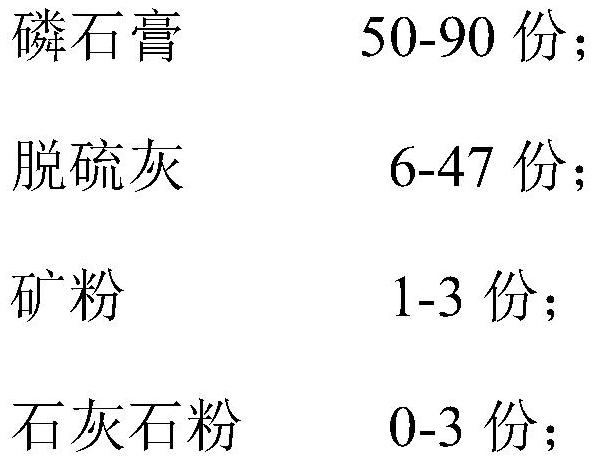

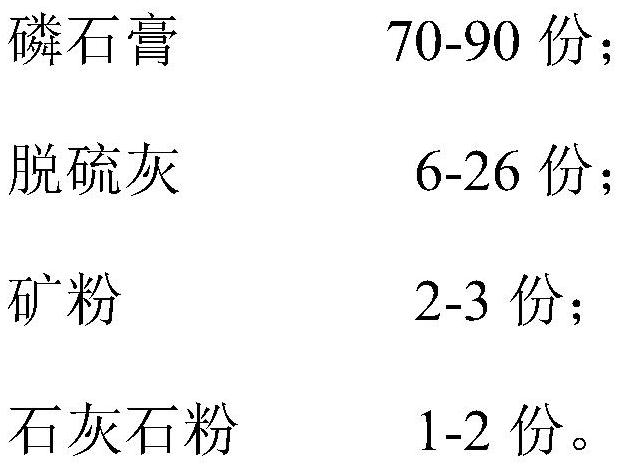

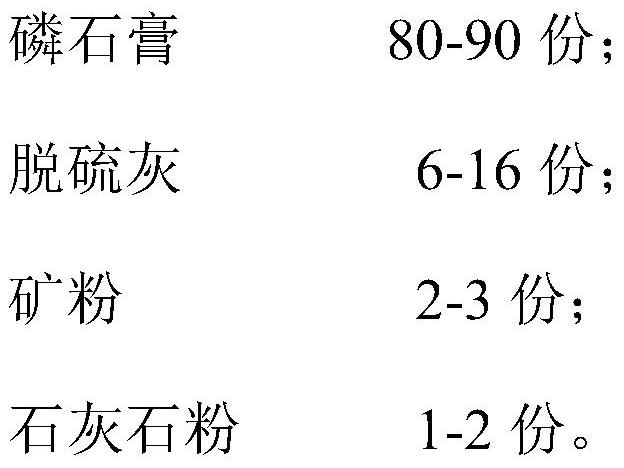

Method used

Image

Examples

Embodiment 1

[0044] The present embodiment provides a cement retarder and a preparation method thereof, comprising the following steps:

[0045] Step 1, weighing 50% of phosphogypsum, 49% of desulfurized ash, 1% of mineral powder and 0% of limestone powder. Among them, the specific surface area of mineral powder is 510m 2 / Kg.

[0046] Step 2, mixing the above raw materials, atomizing and spraying water, so that the water content of the mixture is 5%.

[0047] Step 3. Put the above mixture in an aging tank and age it in a closed environment for 24 hours. The temperature range during the aging process is 50-80° C. to obtain a cement retarder.

Embodiment 2-6

[0049] With reference to the preparation method of the cement retarder in Example 1, according to the mass percentage of each raw material in Table 1, the cement retarders of Examples 2-6 and Comparative Examples 1-3 were prepared.

[0050] Table 1

[0051]

[0052] In Table 1, slag is blast furnace slag that has not been ground. The specific surface area is 100m 2 / Kg.

[0053] In limestone powder, the content of calcium carbonate is 85%, and the specific surface area is 600m 2 / Kg.

[0054] The specific surface area of fly ash is 800m 2 / Kg.

Embodiment 7

[0056]Get the cement retarder of embodiment 1-6 and comparative example 1-4, above cement retarder and cement clinker, limestone and high silicon are mixed and ground respectively, and the percentage composition of each raw material is as shown in table 2, Cement corresponding to the cement retarders of Examples 1-6 and Comparative Examples 1-4 were prepared.

[0057] Table 2

[0058]

[0059]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com