A real-time self-adaptive adjustment system and adjustment method for laser-arc hybrid welding

A technology of self-adaptive adjustment and light wire spacing, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of poor discharge stability, low energy density of arc heat source, welding efficiency and application convenience, etc., to achieve Precisely adjust and eliminate the effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

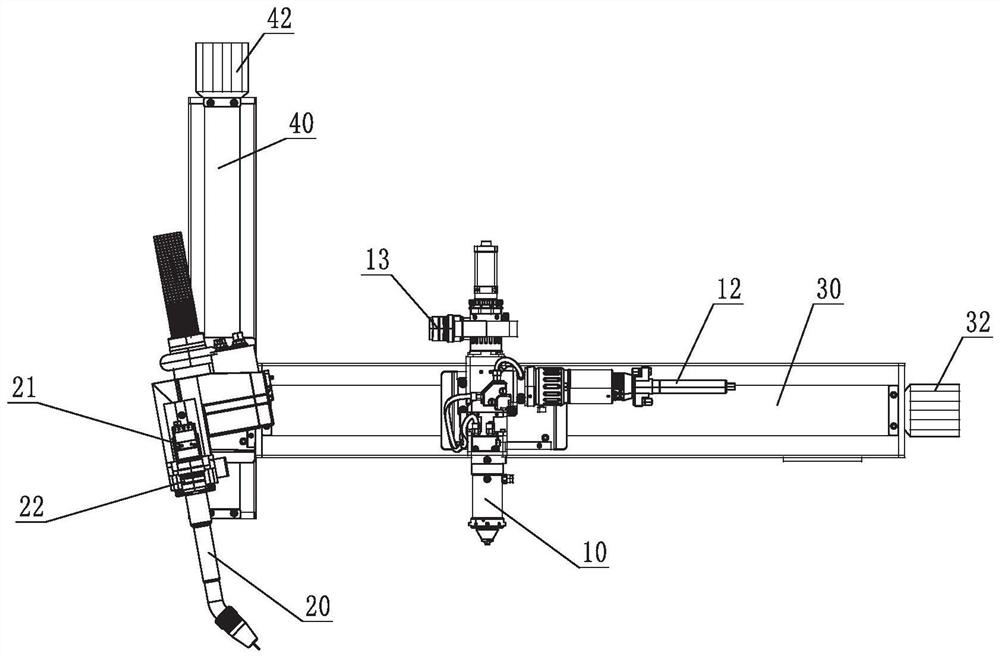

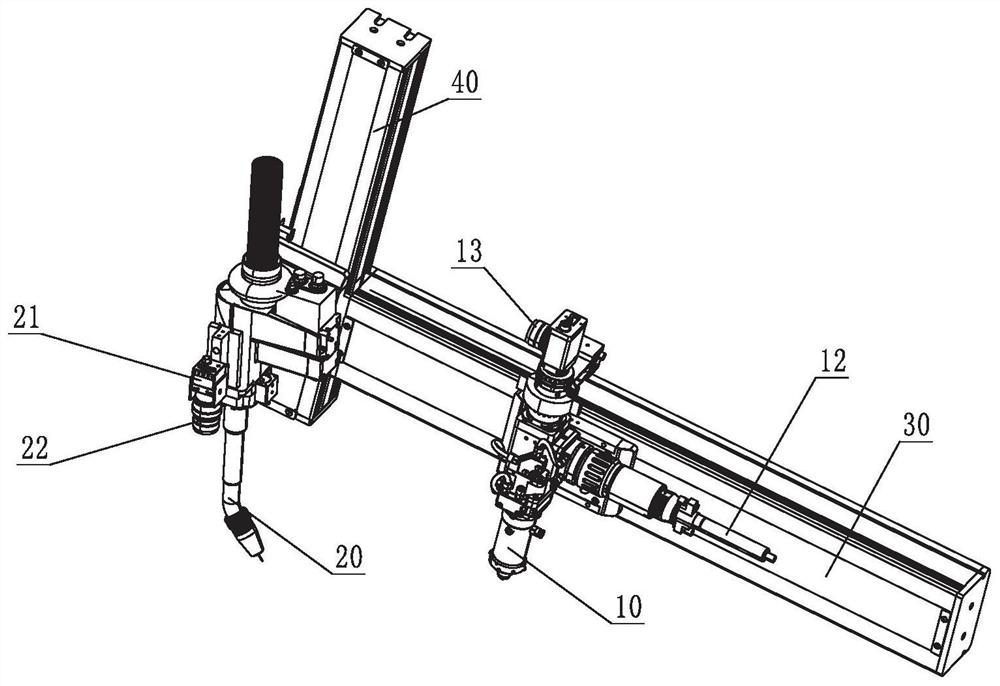

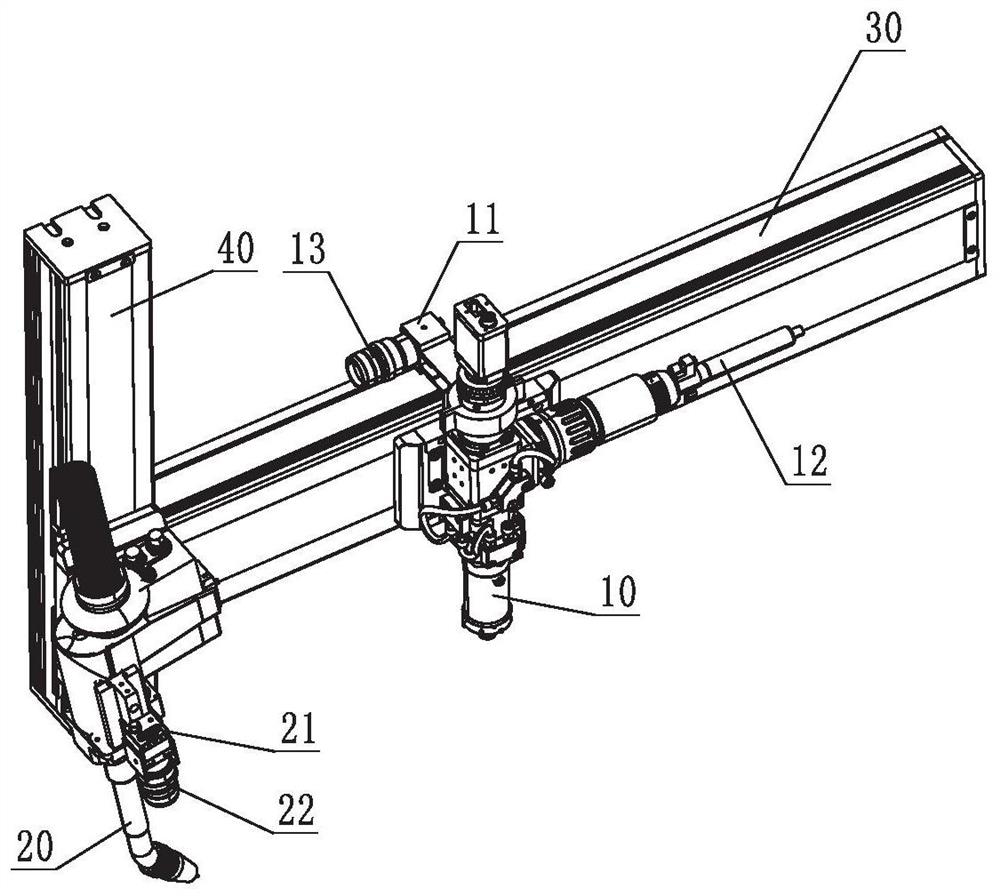

[0035] Embodiment 1: as Figure 1-Figure 3 As shown, a real-time adaptive adjustment system for laser-arc hybrid welding of the laser-arc hybrid welding in this embodiment includes a transverse guide rail movement mechanism 30 and a vertical guide rail movement mechanism 40, wherein the transverse guide rail movement mechanism 30 includes a transverse movement The slider 31 is used to fix the laser welding output head 10; it also includes a first drive motor 32 installed on the right end of the mechanism, which is used to control the forward and reverse movement of the lateral movement slider, and then the left and right movement of the laser welding output head 10 . On described vertical guide rail movement mechanism 40, comprise vertical movement slide block 41, be fixed with arc welding torch 20 on vertical movement slide block 41, vertical guide rail movement mechanism 40 controls arc welding welding torch 20 to move up and down, to adapt to The vertical position of the a...

Embodiment 2

[0037] Embodiment 2: A real-time self-adaptive adjustment method for laser-arc hybrid welding of light wire spacing in this embodiment,

[0038] refer to Figure 4-Figure 6 , before welding, the computer control system inputs the appropriate light wire spacing value, and the computer control system will control the horizontal guide rail movement mechanism 30 and the vertical guide rail movement mechanism 40 to adjust the horizontal position of the laser beam and the vertical position of the welding torch to a suitable light wire distance. at the spacing value;

[0039] During the welding process, when the distance between the light wires changes suddenly, the laser beam capture detection system and the welding wire capture detection system operate, and the infrared integrated receiving head transmits the detected position changes to the computer control system in real time, and the computer control system controls the guide rail movement mechanism Adjust the distance between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com