Special machine tool for inner hole boring of ultralong large-diameter cylinders

A special machine tool and large-diameter technology, which is applied in the direction of boring/drilling, parts of boring machine/drilling machine, large fixed members, etc., can solve the problems of incompetent diameter, long length, heavy weight, etc., and achieve shortening of clamping and adjustment The effect of flat time, improving work efficiency and eliminating vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

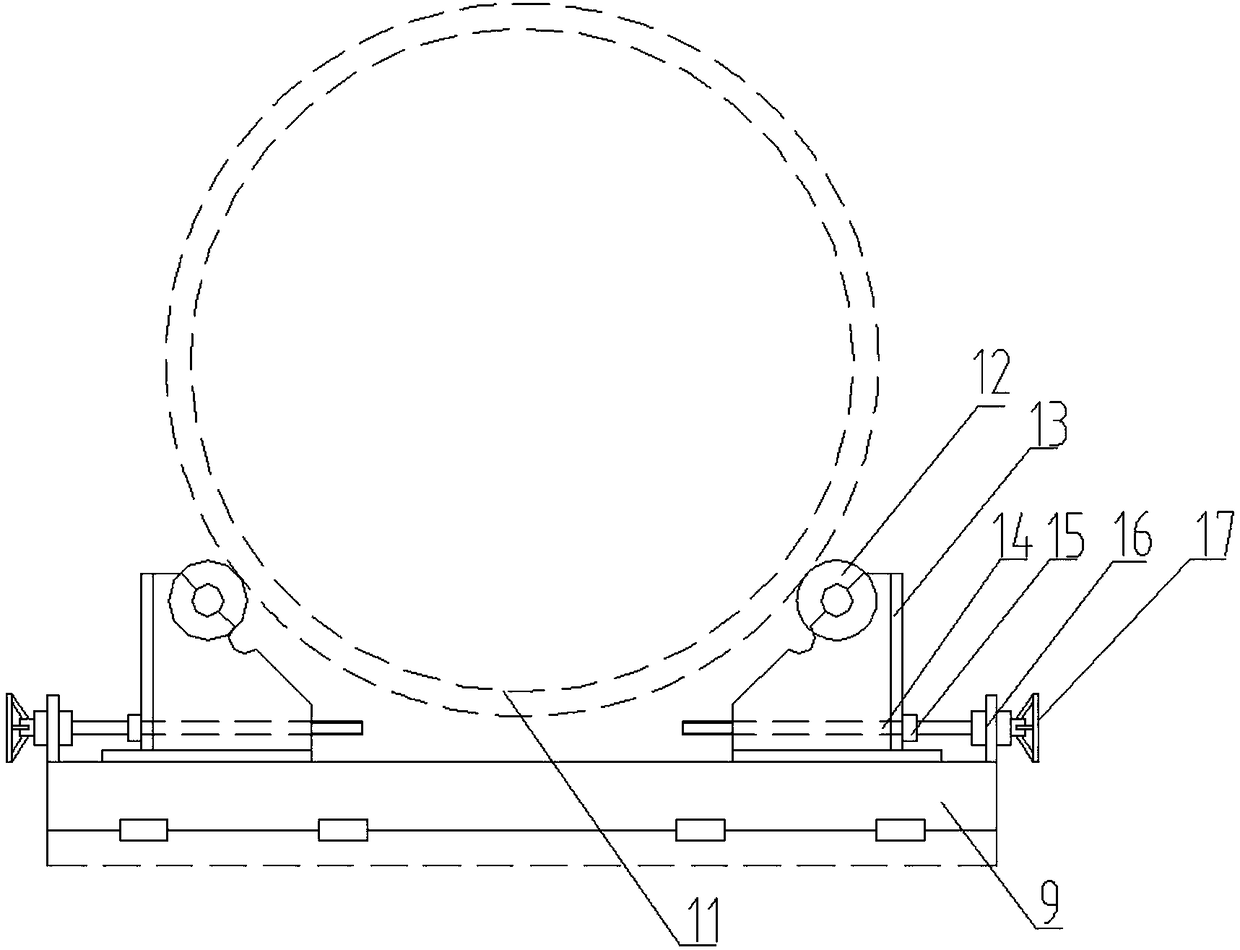

[0030] Such as Figure 1 to Figure 7 As shown, a special machine tool for boring the inner hole of a super long-diameter cylinder, including a fixed platform 9, a machine base 8, a boring bar 3, a boring bar cantilever fixing device 6, a fixing frame pull rod 7, a cutter head assembly 4, and a fast and slow knife Feed system 5, cylinder body 11, positioning support wheel group and transmission device 2; wherein, the left and right sides of the fixed platform 9 are respectively provided with machine bases 8, and the top of the machine base 8 on the left side is connected with the boring bar 3 by fastening bolts One end of the boring bar 3 is fixedly connected, and the top of the end of the boring bar 3 is fixedly connected with a boring bar cantilever fixing device 6, and the boring bar cantilever fixing device 6 is threadedly connected with the fixing frame pull rod 7 on the left side of the machine base 8 through a lever nut. The boring bar 3 is provided with guide rails alon...

Embodiment 2

[0039] Such as Figure 8 As shown, the special machine tool for boring the inner hole of a super long-diameter cylinder described in Embodiment 2 has the same structure as Embodiment 1. In addition, the positioning support roller set also includes several sets of auxiliary pressure roller assemblies, The auxiliary pressure roller assembly has several groups, and the auxiliary pressure roller assembly includes a top auxiliary pressure roller 41, an upper beam 42, and a gantry frame 43. The gantry frame 43 is located at the top of the fixed platform 9, and the top of the gantry frame 43 spans An upper crossbeam 42 is provided, and the bottom of the upper crossbeam 42 is provided with a top auxiliary pressure roller 41 , and the top auxiliary pressure roller 41 is in conflict with the highest point of the top of the cylinder body 11 . The cylinder 11 will vibrate up and down due to the cutting force during processing, causing the tool to "shock". The vibration of the cylinder 11 ...

Embodiment 3

[0041] Such as Figure 9 As shown, the guide rail on the boring bar 3 in embodiment 1 considers the accuracy requirements of processing and installation, and the finished linear guide rail assembly can be used, including the linear guide rail 44 installed on the boring bar 3 and the matched tool holder 37 The guide rail slide block 45 of inner side.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com