Automatic hydraulic support advancing method for breaking bottom plate

A technology of hydraulic support and moving frame, which is applied in the direction of mine roof support, earth square drilling, mining equipment, etc., which can solve the problem of coal stacking in front of the frame, and achieve the effect of reducing coal stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

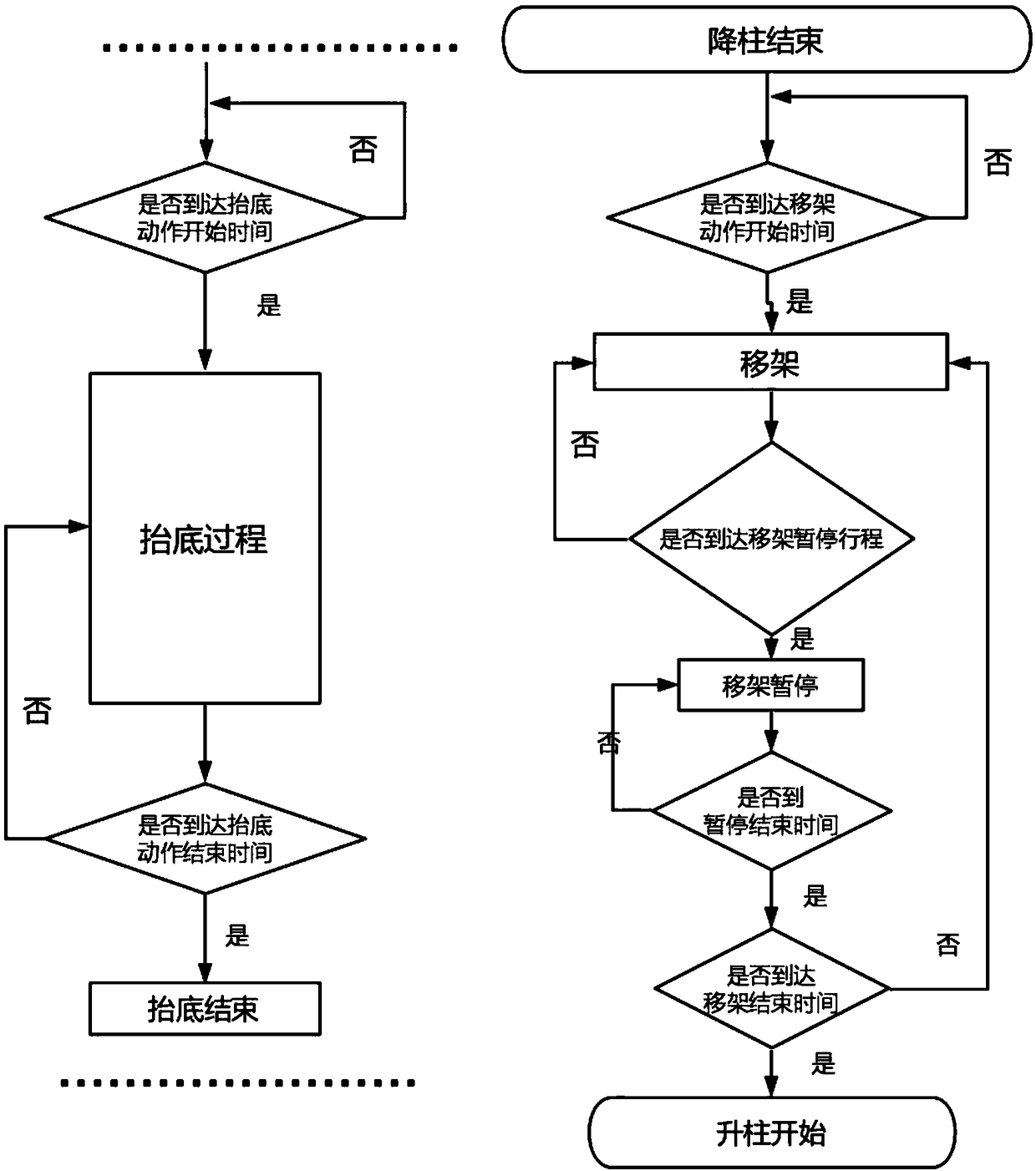

[0025] An automatic frame-moving method for hydraulic supports aimed at broken bottom plates. By adding the function of "pause frame-moving, hold bottom up" during the frame-moving process, the frame-moving action is suspended multiple times during the frame-moving process, and the lifting motion is suspended during the frame-moving action. Bottom holding, so that the moving of the hydraulic support forms a step-up process, reducing the phenomenon of coal piles during the moving process.

[0026] See attached figure 1 , the present invention adopts the support controller to execute the automatic rack moving control operation program, and the specific steps are as follows:

[0027] The first step is the column lowering step: the support controller executes the column lowering step in the auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com