Washing machine

A technology for washing machines and washing tubs, applied in the field of washing machines, can solve the problems of limited location, increasing the rotating tub, limiting the volume of the rotating tub, etc., and achieves the effect of reducing the occupied space and reducing the inclination angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

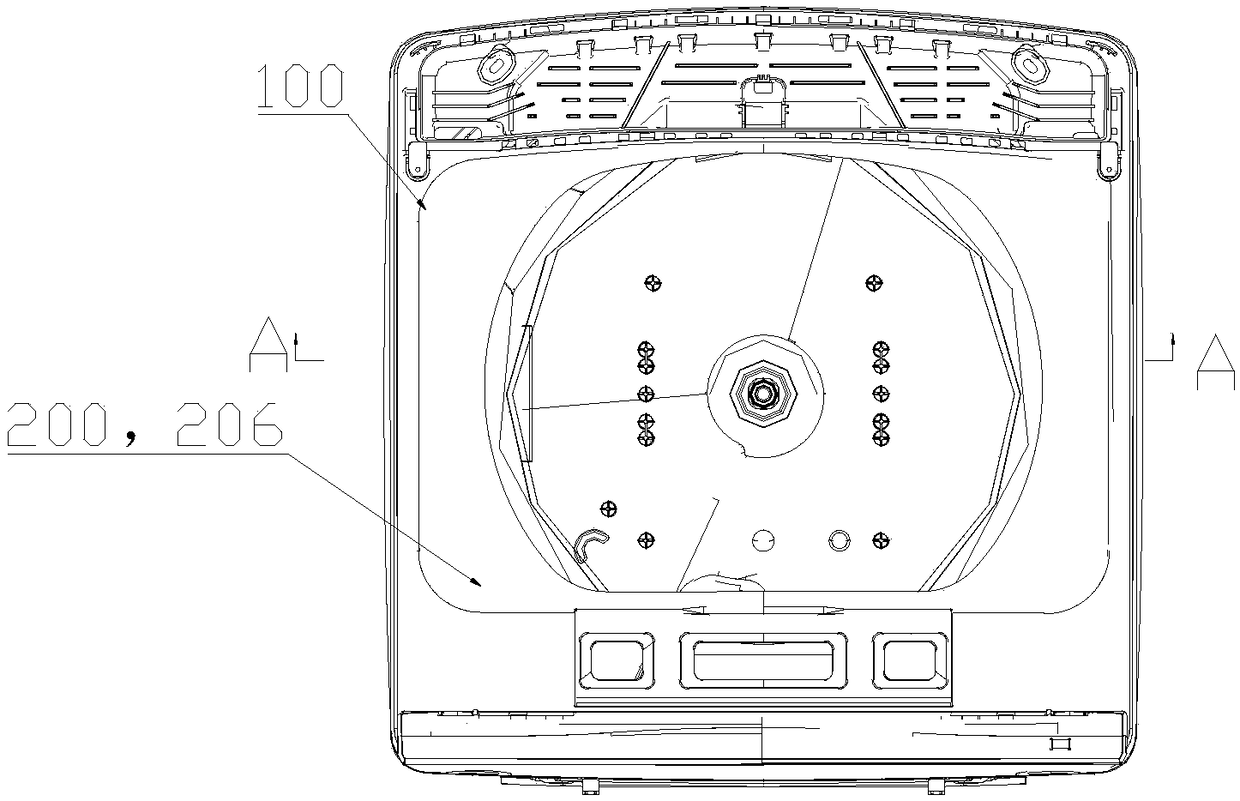

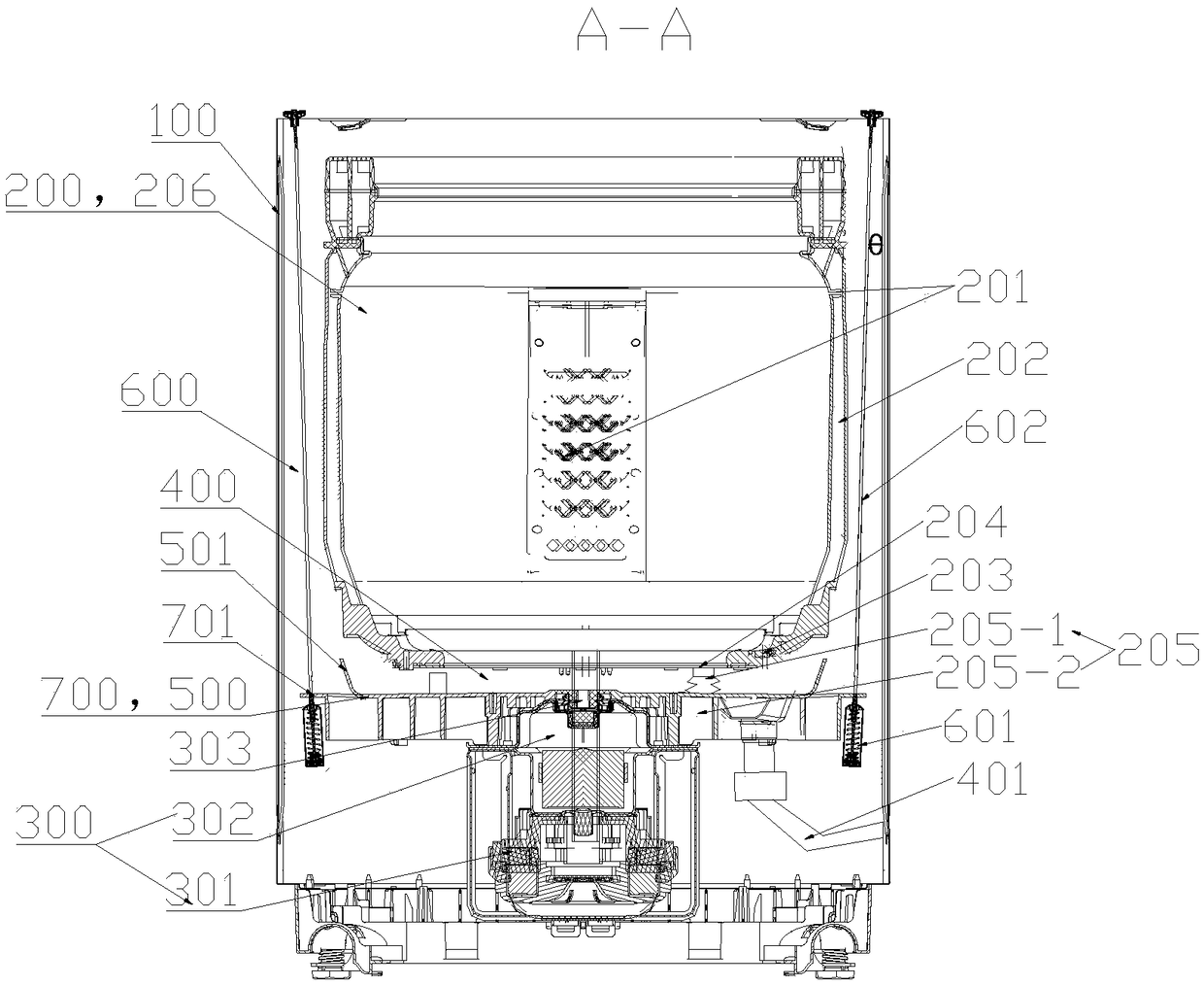

[0046] Such as Figure 1-3 As shown, a capacity-expanding washing machine with a water-retaining structure includes a box body 100, an inner tub 200 disposed in the box body 100, and a drive device 300 for driving the inner tub 200 to rotate, and also includes a drive device 300 for blocking water from the inner tub 200. A water-retaining structure for the overflow of discharged water. The water-retaining structure is located at the lower part of the bottom of the inner bucket 200 as a whole, and the inner bucket 200 has the function of holding water.

[0047]By setting the water retaining structure, on the one hand, when the water is discharged from the inner bucket 200, the water is blocked by the water retaining structure to prevent the water from overflowing; The partial structure between the side wall of the inner tub 200 and the box body 100 does not restrict the expansion of the inner tub 200 , and provides sufficient space for the expansion of the inner tub 200 .

[0...

Embodiment 2

[0055] Such as Figure 1-3 As shown, this embodiment is a further limitation of Embodiment 1. In this embodiment, the water retaining structure includes a mounting plate 500 and a water retaining rib 501 arranged on the mounting plate 500, and the mounting plate 500 and the water retaining The ribs 501 enclose the water collection cavity 400 . By arranging the installation plate 500 and the water retaining rib 501, and enclosing them to form the water collection cavity 400, the structure is simple and easy to process and shape.

[0056] The water collecting chamber 400 is located in the middle of the mounting plate 500, so that the center of gravity of the water retaining device can be more easily coincided with the center, and the offset can be reduced.

[0057] The water retaining rib 501 is ring-shaped, and the water retaining rib 501 and the installation plate 500 enclose to form a ring-shaped water collecting cavity 400 .

[0058] Further, the water retaining rib 501 is...

Embodiment 3

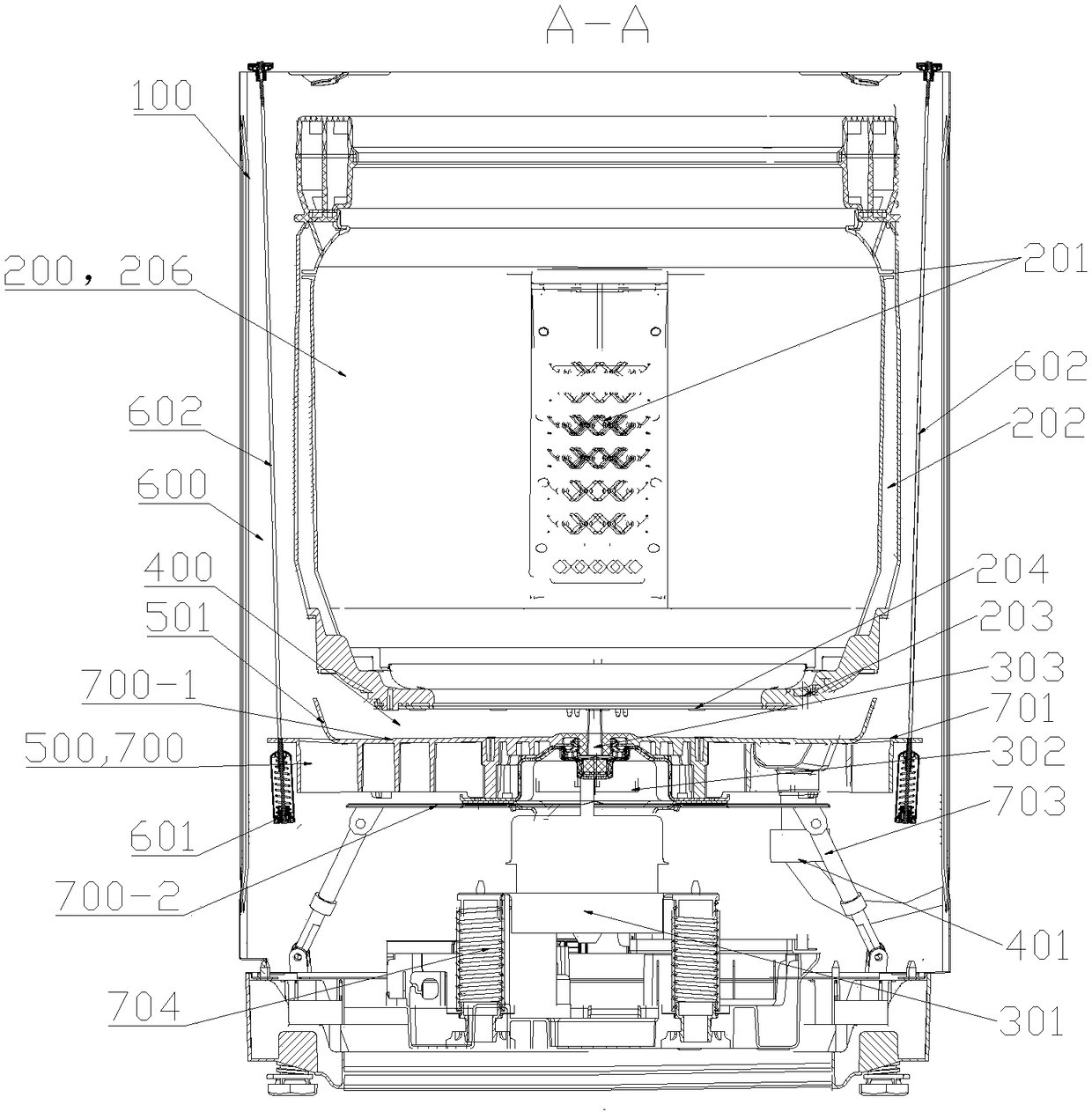

[0077] Such as Figure 1-2 As shown, a washing machine includes a box body 100, a washing bucket 206 disposed in the box body 100, and a driving device 300. The output shaft 303 of the driving device 300 is connected to the washing bucket 206 for driving the washing bucket 206 to rotate. It includes a suspension shock absorber 600 and a mounting part 700 arranged at the lower part of the washing tub 206, the driving device 300 is installed on the mounting part 700, one end of the suspension shock absorber 600 is connected with the box body 100, and the other One end is connected with the mounting part 700 .

[0078] By setting the mounting part 700 under the washing tub 206, the suspension shock absorber 600 is installed on the mounting part 700. Since the mounting part 700 is lower than the washing tub 206, the longitudinal height of the mounting part 701 is reduced, making the installation The inclination angle θ between the rear suspension shock absorber 600 and the box si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com