Tensioning and fixing method and device for mining endless rope winch tail wheel system

A technology of infinite rope winch and tail wheel, which is applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of waste, the slippage of the winch drum, and the inability to adjust the tension, and achieve the effect of simplifying the structure, eliminating the slippage and saving manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

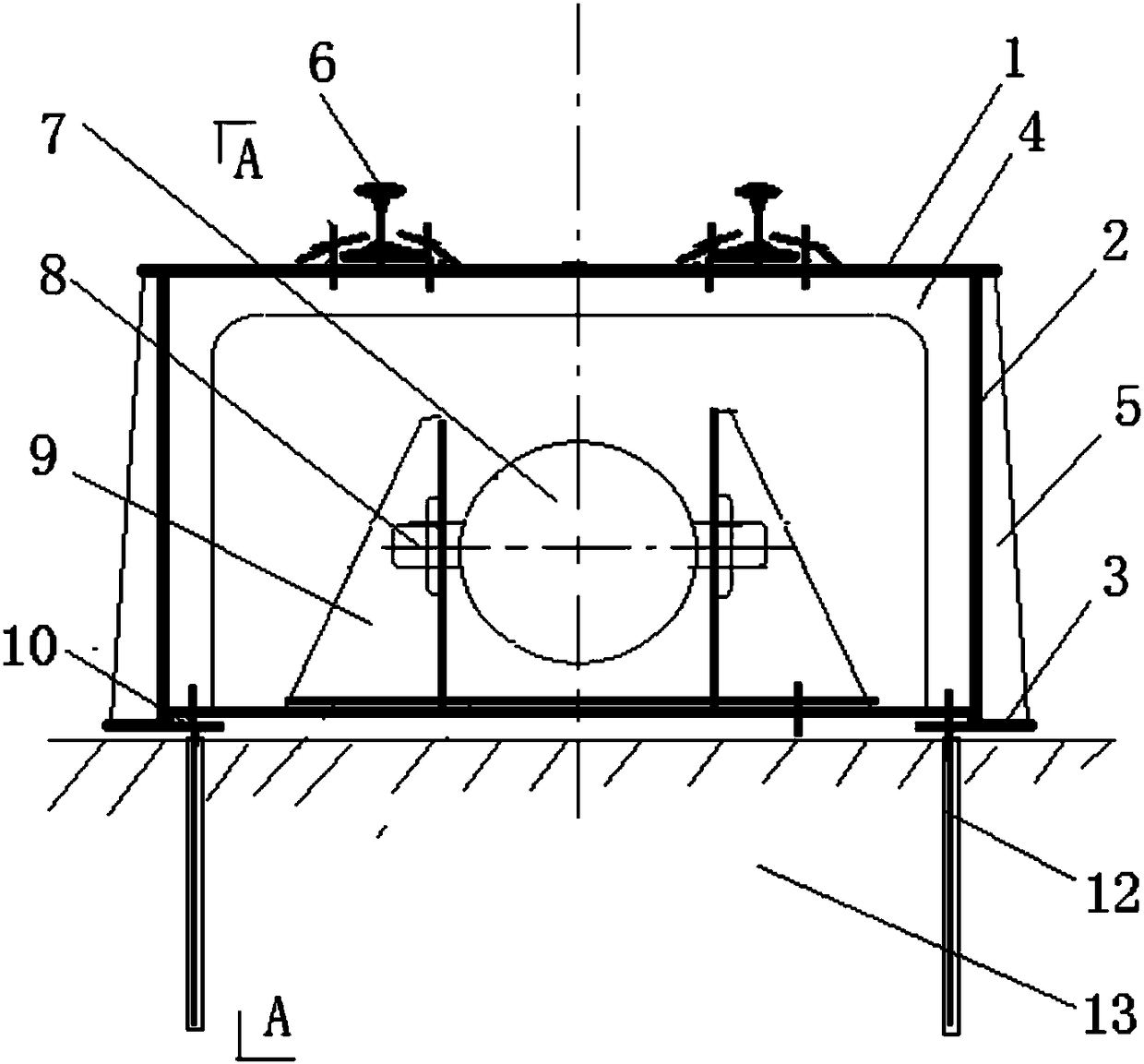

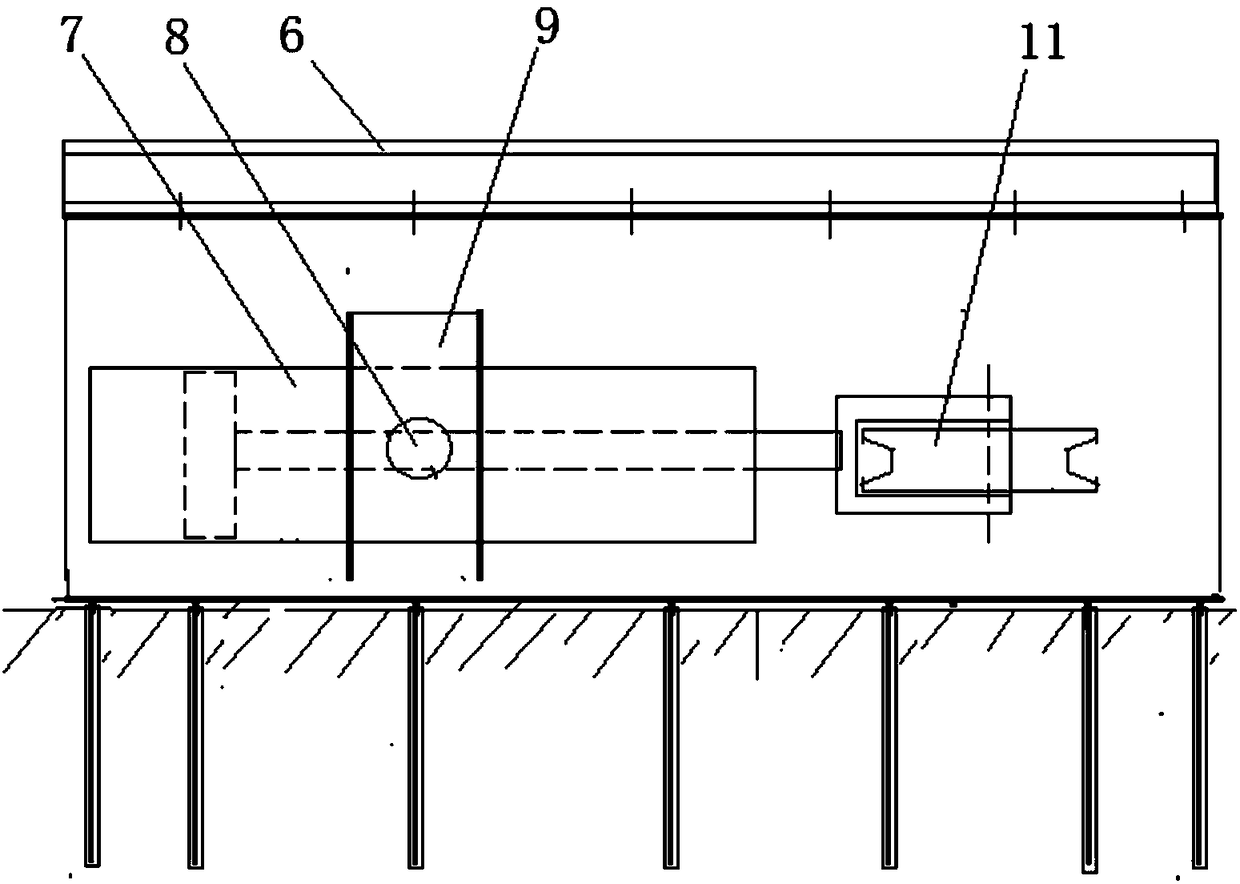

[0028] like figure 1 , figure 2 and Figure 5 As shown, a method for fixing and tensioning the tail wheel system of a single-rope mine endless rope winch, the steps are as follows:

[0029] Step 1. Before the tail wheel system of the underground endless rope winch is arranged, a load-bearing device is first made in the Inoue factory. The load-bearing device is a steel structure frame with an "n" section, and the top cover plate 1 and the vertical plate are supported. 2 and the pressure foot plate 3 are welded; the inner section of the steel structure frame is uniformly welded with n-type ribs 4, and the outer side is welded with vertical ribs 5, and anchor holes 10 are provided on the protruding parts of both sides of the pressure foot plate 3, through which anchor holes 10. The anchor rod 12 can be used to anchor the bottom plate of the roadway; the upper rail 6 is fixed on the top surface of the steel structure frame by a pressure plate and bolts; The ground is transpor...

Embodiment 2

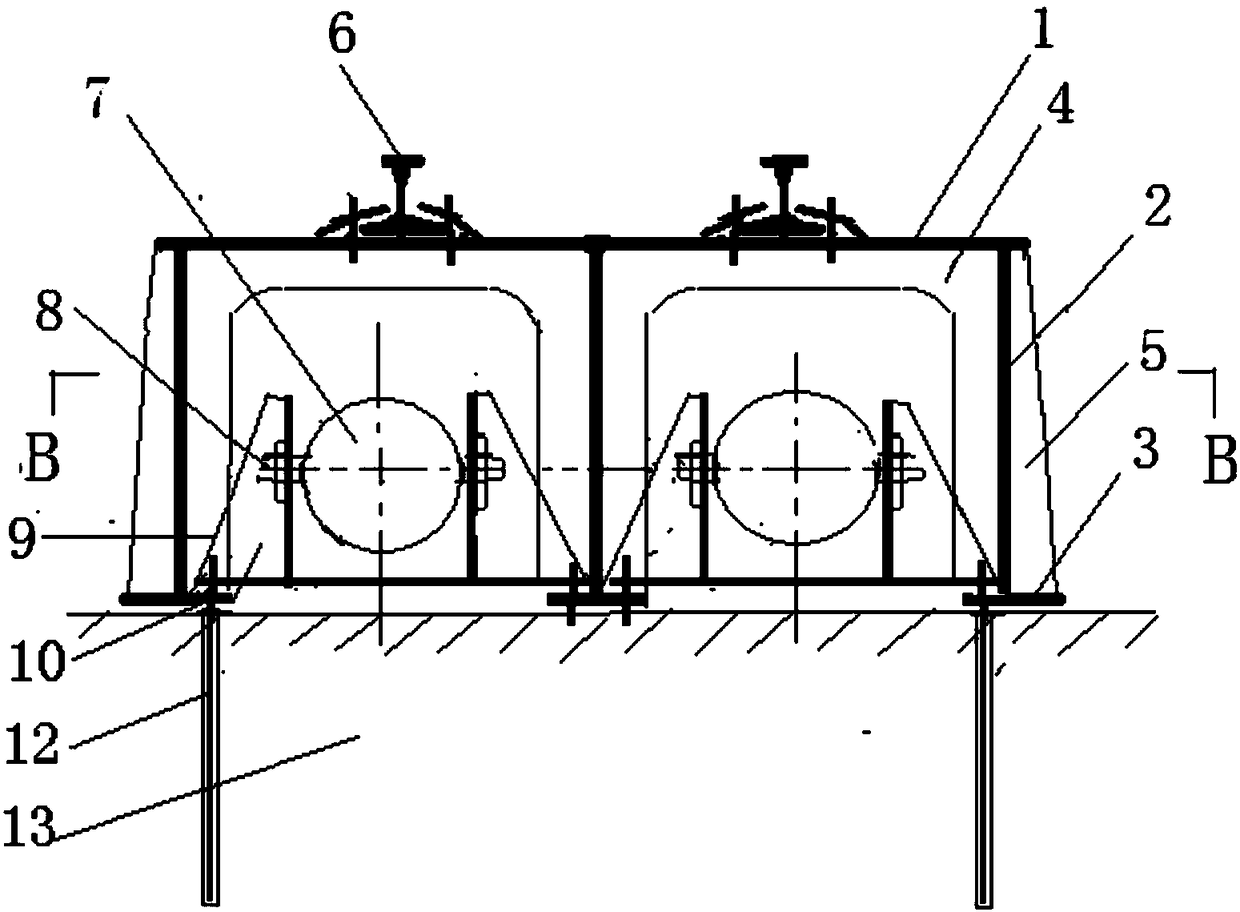

[0038] like image 3 , Figure 4 and Image 6As shown, a method for fixing and tensioning the tail wheel system of a double-rope endless rope winch for mining, the steps are as follows:

[0039] Step 1. Before the tail wheel system of the underground endless rope winch is arranged, a load-bearing device is first made in the Inoue factory. The load-bearing device is a steel structure frame with an "m" cross-section, which consists of a top cover plate 1 and a supporting vertical plate 2 and the pressure foot plate 3 are welded; the inner section of the steel structure frame is evenly welded with "n" type ribs 4, and the outer side is welded with vertical ribs 5, and anchor holes 10 are provided on the protruding parts of both sides of the pressure foot plate 3, through which Anchor hole 10 can be anchored on the bottom plate of roadway with anchor rod 12; On the top surface of steel structure frame, fix upper track 6 by pressing plate and bolt; Require the width of bearing de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com