Material tracking system for continuous rolling production line and tracking method

A tracking system and production line technology, applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of program reading, searching, modification difficulties, lack of versatility, unclear structure, etc., to achieve rich content and universal Strong performance and easy programming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the continuous rolling production line, material tracking is an important function of the main rolling line program. It does not directly control specific equipment, but the rolling piece head and tail tracking signals generated by it are necessary for all other automatic control functions. one of the conditions. The automatic control functions involved include: speed cascade adjustment, impact compensation, micro tension control, looper control, looper lifting and lowering control, water cooling control, waste detection control, stand jumping control, simulated rolling, etc.

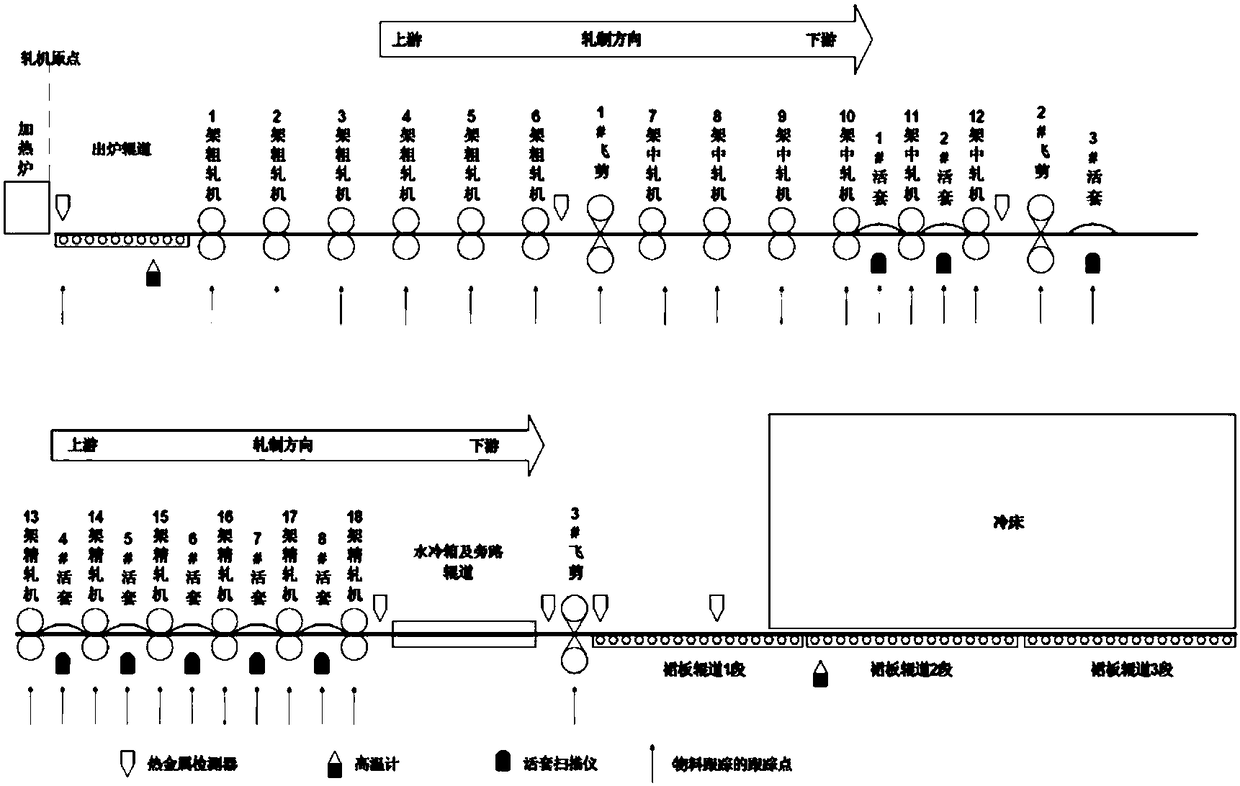

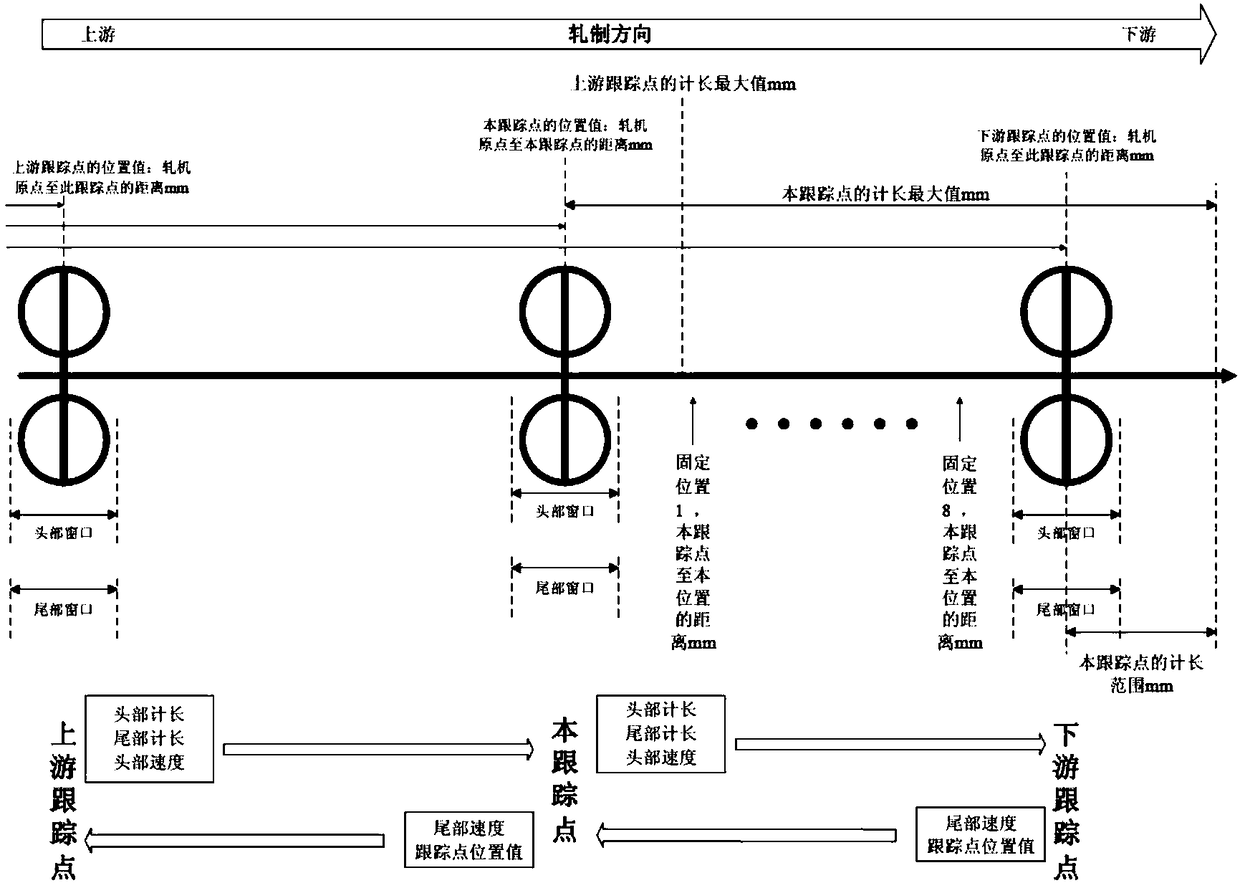

[0027] The continuous rolling production line is composed of a series of racks, flying shears, hot metal detectors (HMD), loopers and their scanners. We define each important equipment (customized pre-tracking equipment) as a tracking point (see process layout diagram), and each tracking point has its own tracking area (the tracking area starts from this tracking point and ends after the downs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com