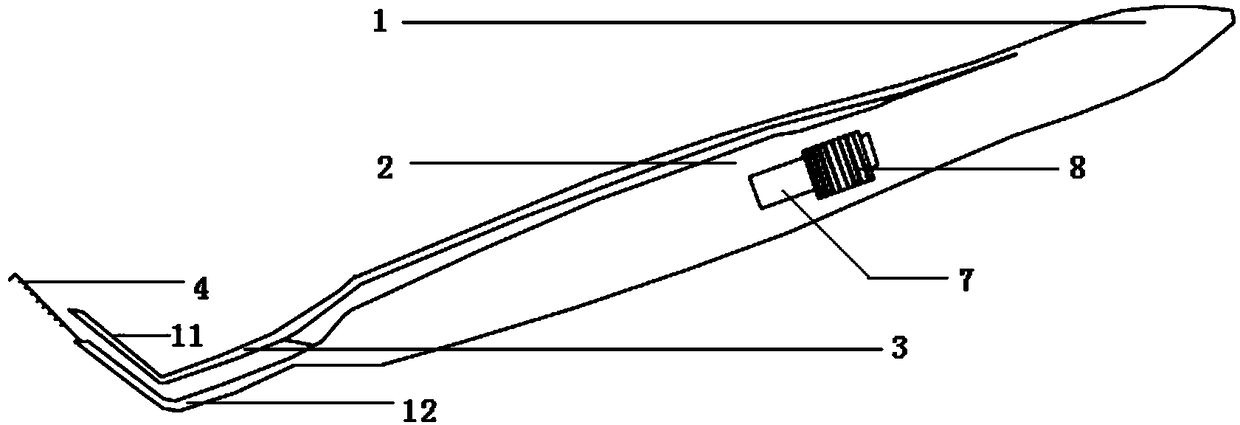

Capsulorhexis forceps

A technique of capsulorhexis forceps and a forceps handle, applied in the field of capsulorhexis forceps, can solve the problems of surgical failure, decreased surgical quality, long growth curve, etc., so as to improve surgical quality and safety, reduce surgical difficulty and risk, and improve success rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

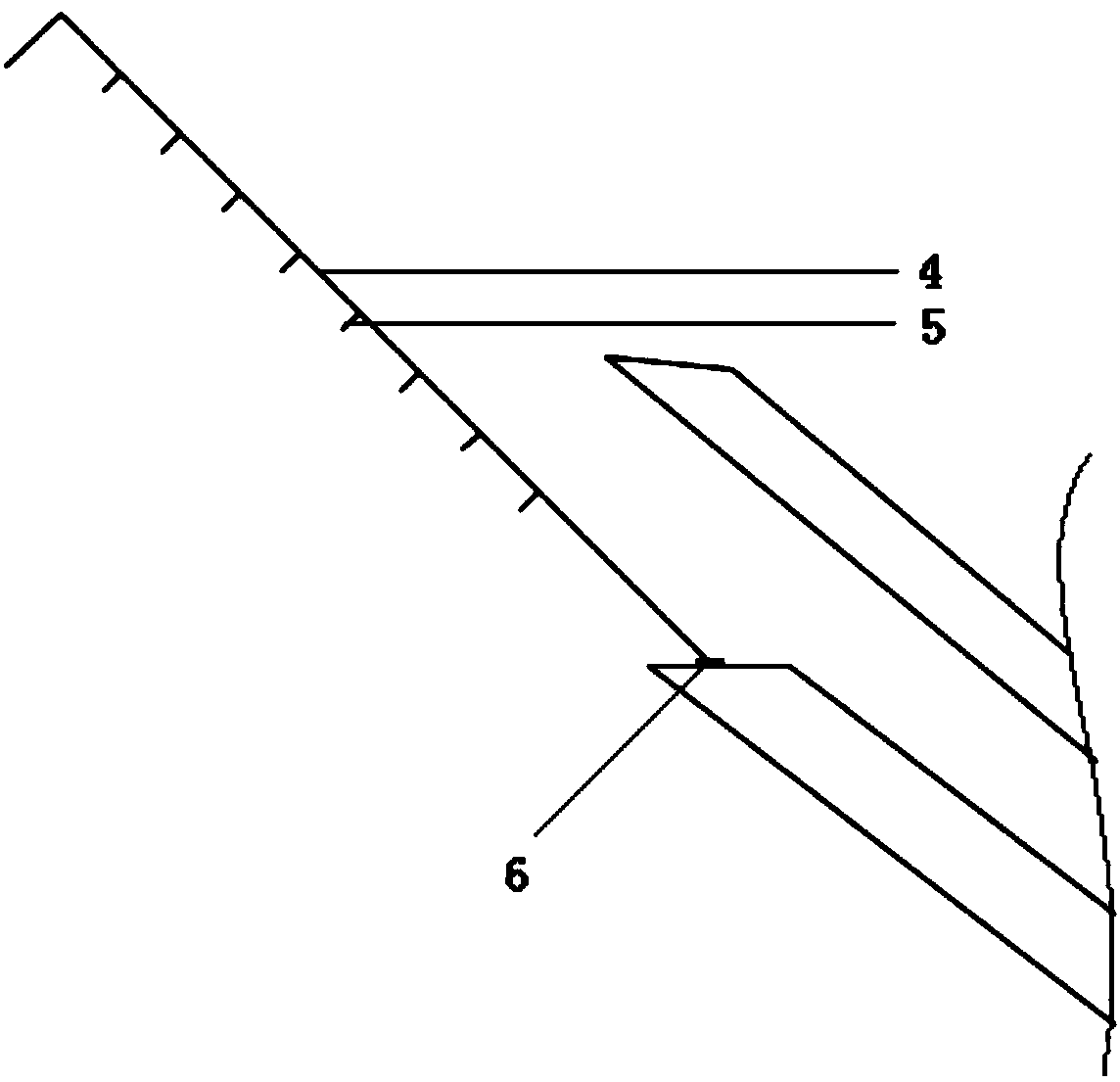

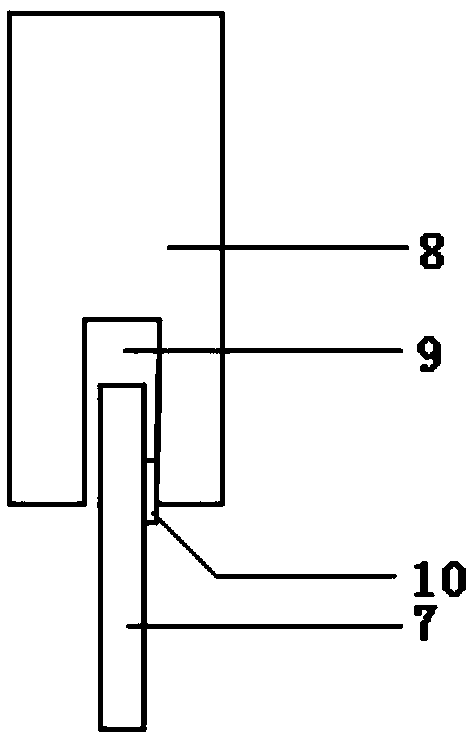

[0057] On the basis of Embodiment 1, in this embodiment, we explain the pushing structure of the second auxiliary rod. combine Figure 5 and Figure 6 , the tail of the auxiliary rod 4 is connected with a push linkage rod 13, the tip of the clamping section has a through hole that can accommodate the extension of the auxiliary rod, the tail of the push linkage rod is provided with several racks 14, and the The rack 14 is cooperatingly provided with a gear 15, and also includes a rotating wheel 16. The rotating wheel 16 and the gear 15 are linked by a fixing piece. The said hand section has a through hole 17, and the fixing piece 18 passes through the through hole 17. , the rotating wheel 16 and the gear 15 are located on the outside and inside of the tweezers handle wall respectively.

[0058] By turning the rotating wheel, the gear can be driven to rotate, and then the gear rack matched with it can be driven to move, so that the auxiliary rod connected with the linkage rod ...

Embodiment 3

[0064] In this embodiment, further preferred reference Figure 7 , the front end of the auxiliary rod is provided with a plurality of pointed protrusions along the direction of the auxiliary rod, and these pointed protrusions are located on an arc rod.

[0065] At the same time, preferably, as Figure 7 The spikes shown in are equally spaced.

[0066] Applying this structure to Embodiment 1 or Embodiment 2, the dot-like gaps forming the capsular flap are evenly distributed, making it easier to tear off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com