Feed for improving growth performance of mutton sheep and preparation method thereof

A growth performance and feed technology is applied in the field of feed and its preparation for improving the growth performance of mutton sheep, which can solve the problems of slow weight gain and high feed-to-weight ratio of mutton sheep, and achieve the effects of promoting rumen development, increasing the number of ruminations, and improving nutrient digestibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention also provides a preparation method of the feed, which comprises pulverizing the raw materials, mixing them, and pressing them into granular feeds by means of a granulation method.

[0027] In the present invention, the raw materials are pulverized; the pulverization in the present invention can be done using a conventional pulverizer in the field, and the mesh number of the raw materials after the pulverization is preferably 15-20 mesh; in the present invention, after the pulverization of the raw materials, , mix the pulverized raw materials evenly. In the present invention, the mixing is realized by stirring. The present invention does not limit the rotation speed of the stirring, as long as the mixing can be realized.

[0028] In the present invention, the granulation method and equipment can be conventional granulation methods and equipment in the field; the granulation temperature is preferably 68-75°C, more preferably 70°C. The diameter of the pellet ...

Embodiment 1

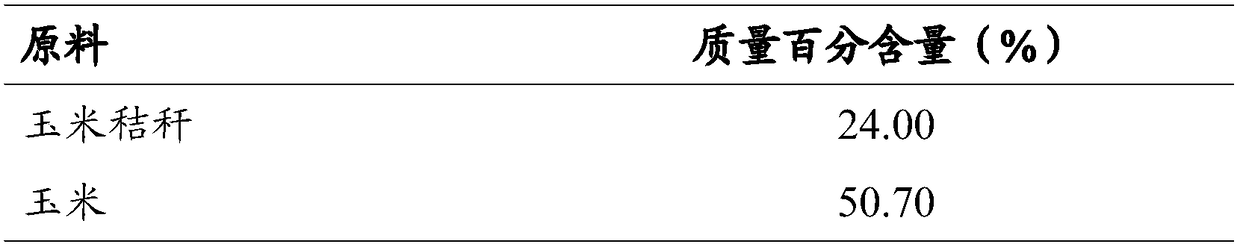

[0038] The feed composition and nutrient levels are shown in Table 2.

[0039] Component and nutritional level (air-dried basis) of feed in table 2 embodiment 1

[0040]

[0041]

[0042]Note: *The concentrated material is composed of cottonseed meal, baking soda, malt root, corn gluten powder, secondary powder, salt, stone powder, premix, etc. Minerals (mg / kg): Fe, 70; Zn, 41; Cu , 8; I, 0.7; Mn, 24; Se, 0.3; Co, 0.3; Vitamins (IU / kg): VA, 2500; VE, 23.

[0043] Preparation method: crush the above raw materials, mix them, and granulate them at 70°C. The diameter of the pellet feed is 6 mm; the length of the pellet feed is 13 mm.

Embodiment 2

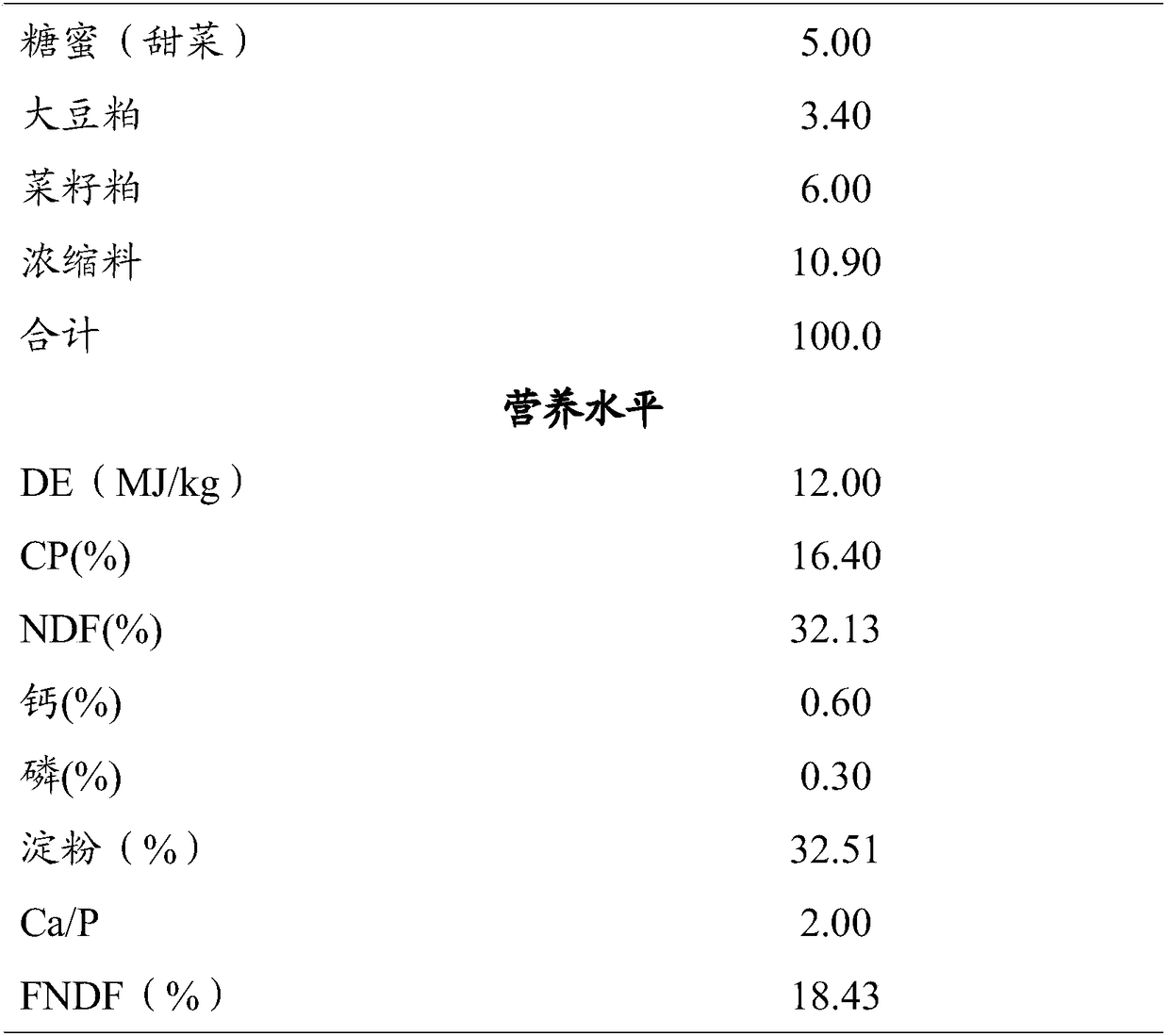

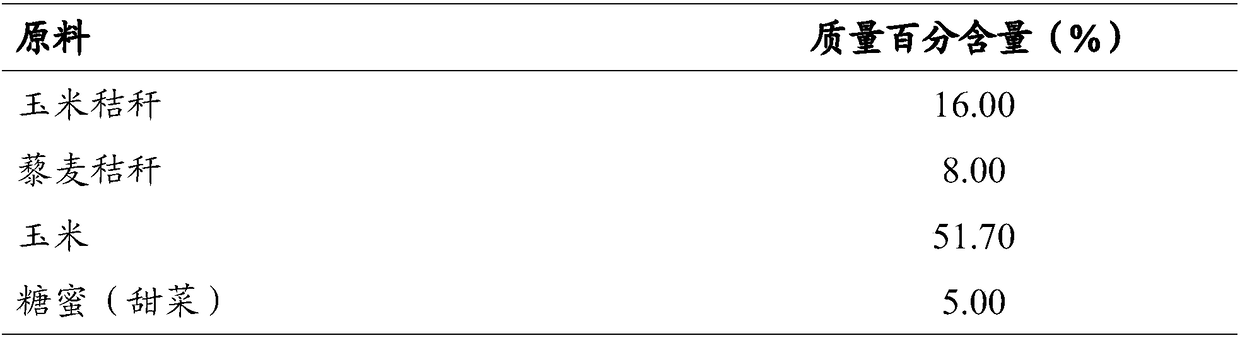

[0045] The feed components and nutrient levels are shown in Table 3.

[0046] Component and nutritional level (air-dried basis) of feed in table 3 embodiment 2

[0047]

[0048]

[0049] Note: *The concentrated material is composed of cottonseed meal, baking soda, malt root, corn gluten powder, secondary powder, salt, stone powder, premix, etc. Minerals (mg / kg): Fe, 70; Zn, 41; Cu , 8; I, 0.7; Mn, 24; Se, 0.3; Co, 0.3; Vitamins (IU / kg): VA, 2500; VE, 23.

[0050] Preparation method: crush the above raw materials, mix them, and granulate them at 70°C. The diameter of the pellet feed is 6 mm; the length of the pellet feed is 13 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com