A cable load measurement device and measurement method based on finite element simulation

A technology for measuring device and cable load, applied in the direction of design optimization/simulation, special data processing application, etc., can solve the problem of not considering the influence of air and cable convection heat dissipation and contact thermal resistance, etc., to achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

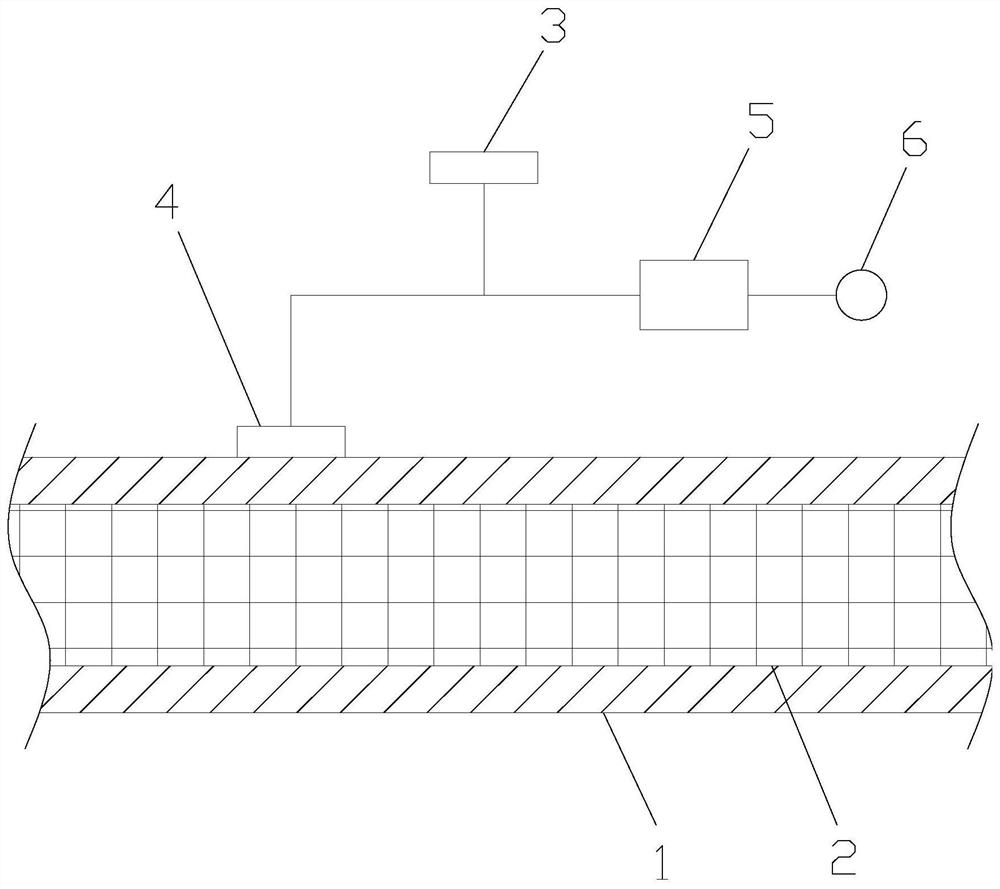

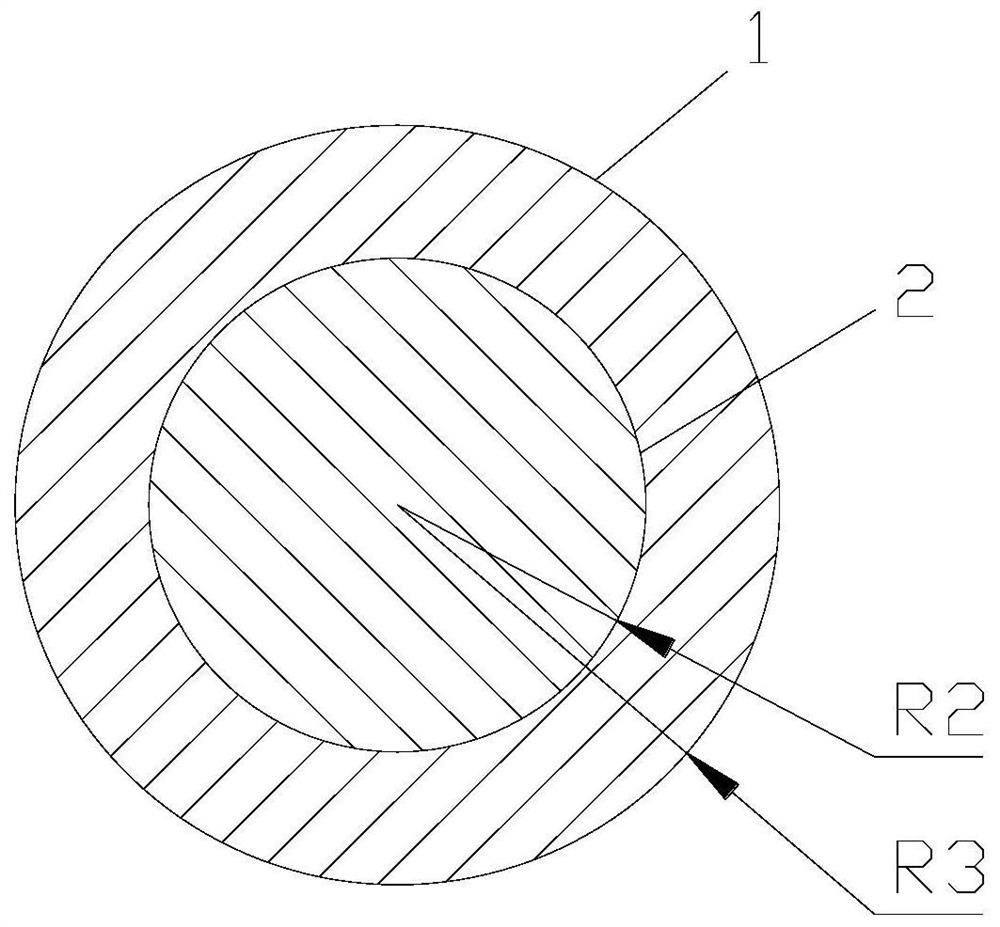

[0063] Model size figure 2 Image: Ambient temperature T c Set to 22 ° C, the conductor 2 of the cable takes Cu, the radius of 2 mm, the insulating layer 1 takes PA66, the maximum radius of 3 mm, the air convection heat dissipation coefficient α is 25w / m 2 · K, conductor 2 and insulation 1 material properties are as follows:

[0064] density Thermal Conductivity Compare Kg / M 3

W / m · k J / KG · K Cu 8900 377 390 PA66 1350 0.3 1100

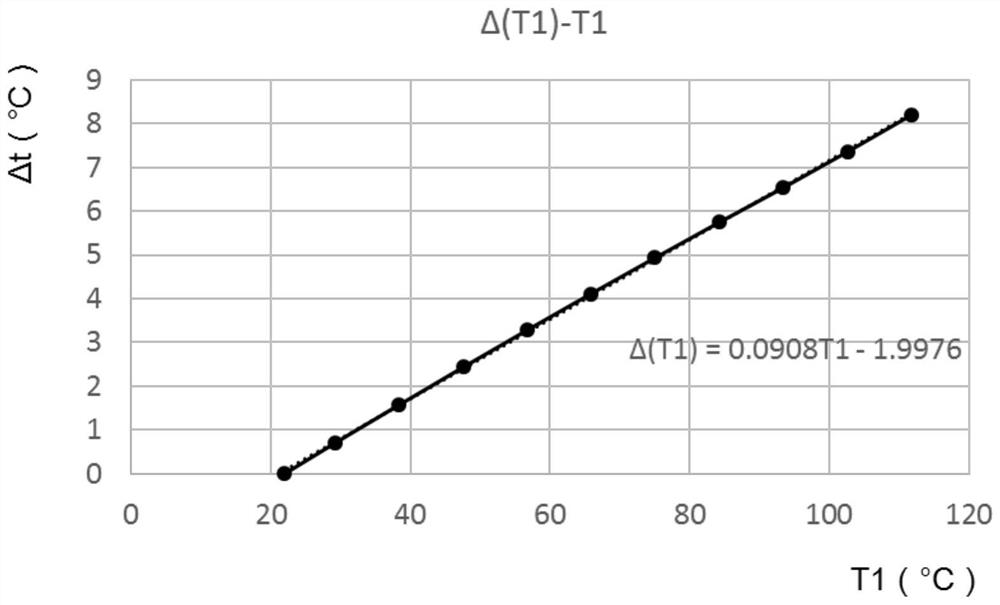

[0065] Established a mathematical model of cable in ANSYS, simulating δ t -T 1 Curve image 3 As shown, it can be obtained by simulation results. t = 0.0908t 1 -1.9976, gumped (3)

[0066]

[0067] Reated R t = 5500W / m · k, λ t = 0.3W / m · k, r 1 = 0.003m, r 2 = 0.002m, r = 0.00137Ω, α = 25w / m 2 · K, T c = 22 ° C into the above formula

[0068]

[0069] The external surface temperature T measured by the temperature probe one 4 measured by the temperature probe 1 The controller 5 calculates the condu...

Embodiment 2

[0071] It is basically the same as the embodiment, just ambient temperature T c Set to 32 ° C, build a mathematical model of cable in ANSYS, simulation get δ t -T 1 Curve Figure 4 As shown, it can be obtained by simulation results. t = 0.0906T 1 -2.8992, substitute (3)

[0072]

[0073] Reated R t = 5500W / m · k, λ t = 0.3W / m · k, r 1 = 0.003m, r 2 = 0.002m, r = 0.00137Ω, α = 25w / m 2 · K, T c = 32 ° C into the above formula

[0074]

[0075] The external surface temperature T measured by the temperature probe one 4 measured by the temperature probe 1 The controller 5 calculates the conductive 2 current I according to the formula (7), and the rated current I with the conductor 2 0 Comparison, if i> i 0 Then explain the flow of the flow exceeds the allowable value, the controller 5 controls the buzzer, issues an alarm, prompting the staff to pay attention.

Embodiment 3

[0077] Model size figure 2 Image: Ambient temperature T c Set to 22 ° C, the cable conductor 2 takes Al, the radius is 2 mm, the insulating layer 1 takes PA66, the maximum radius is 3 mm, the air convection heat dissipation coefficient α is 25w / m 2 · K, conductor 2 and insulating layer 1 The size and material properties are as follows:

[0078] density Thermal Conductivity Compare Kg / M 3

W / m · k J / KG · K Al 2700 237.5 880 PA66 1350 0.3 1100

[0079] Established a mathematical model of cable in ANSYS, simulating δ t -T 1 Curve Figure 5 , By simulation results can be δ t = 0.0923T1-2.0306, giving in the formula (3)

[0080]

[0081] Reated R t = 4500W / m · k, λ t = 0.3W / m · k, r 1 = 0.003m, r 2 = 0.002m, r = 0.00222Ω, α = 25w / m 2 · K, T c = 22 ° C into the above formula

[0082]

[0083] The external surface temperature T measured by the temperature probe one 4 measured by the temperature probe 1 The controller 5 calculates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com