A Combined Split Sliding Bearing Supporting a Rod Rotor

A sliding bearing and tie-rod rotor technology, applied in the direction of shafts and bearings, bearing components, rigid brackets of bearing parts, etc., can solve the problems of surface heating, slow return of hot oil, wear and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is further described:

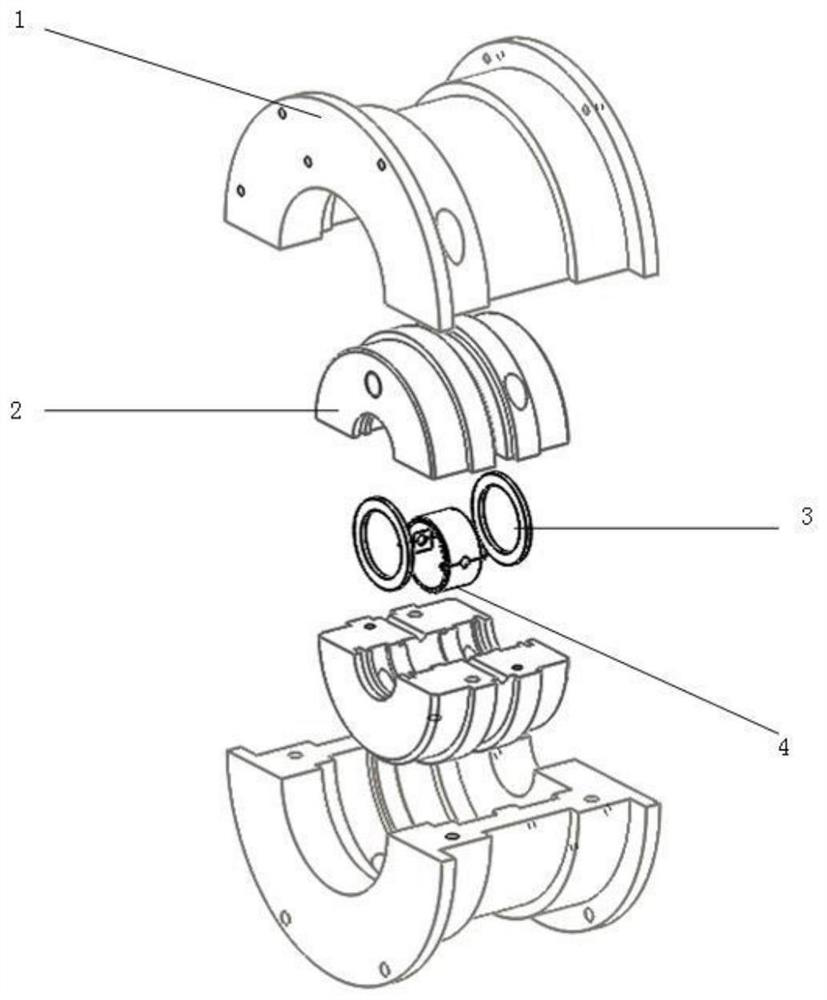

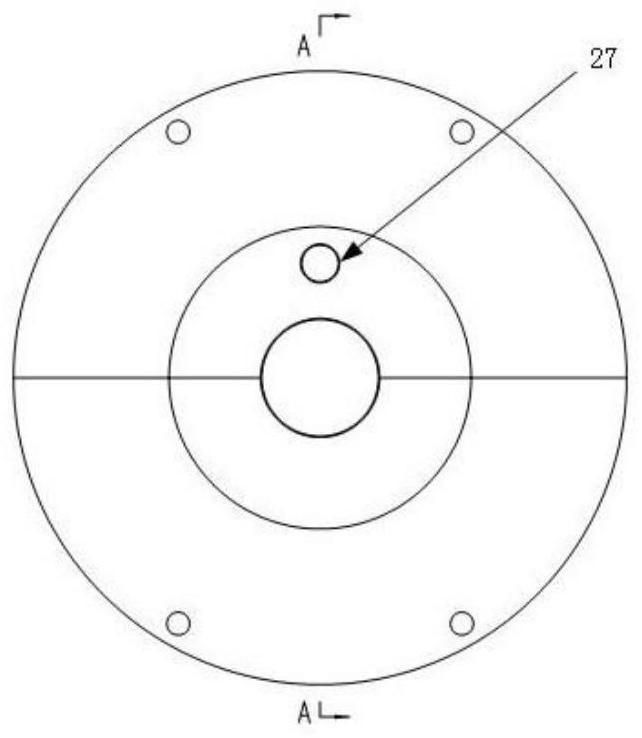

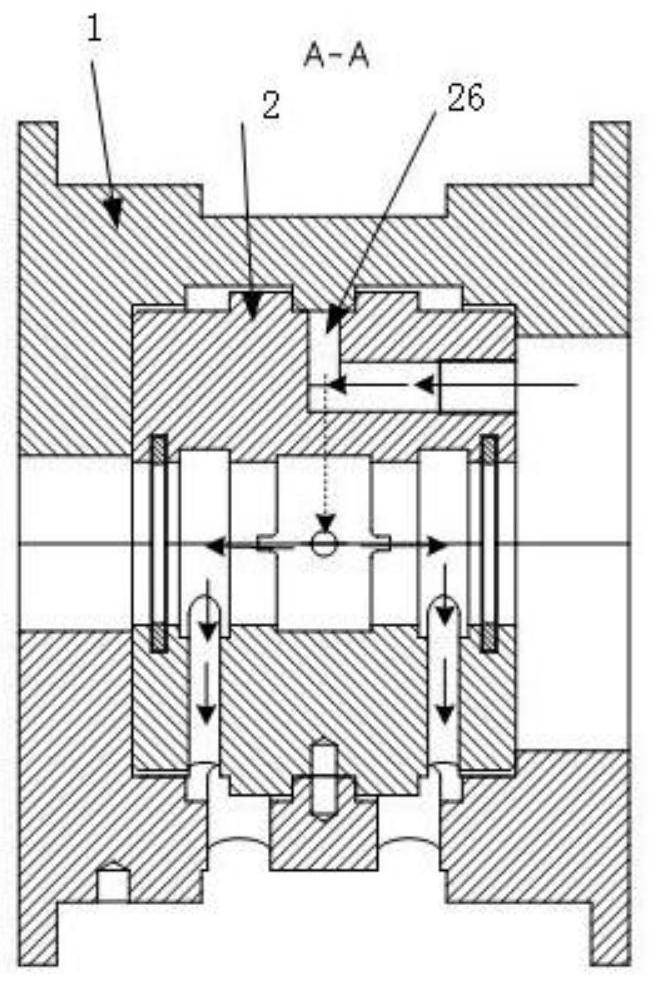

[0022] see Figure 1-Figure 4 , a combined split sliding bearing supporting a tie rod rotor, comprising a bearing housing assembly, a bearing pad 4 and a floating seal ring 3; the bearing pad 4 is arranged in the bearing housing assembly, and floating sealing rings are provided at both ends of the bearing pad 4 in the bearing housing assembly 3. The bearing seat assembly includes the outer body 1 of the bearing seat and the inner body 2 of the bearing seat. The outer body 1 of the bearing seat and the inner body 2 of the bearing seat are both semi-circular. The openings of the inner bodies 2 of the two bearing seats are arranged symmetrically to form the inner bearing seat. The opening of the outer body 1 of the first bearing seat is arranged symmetrically to form the outer bearing seat; the outer bearing seat is sleeved on the outside of the inner bearing seat; the bearing bus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com