UHPC and NC laminated plate of which reinforcement form is triangular space truss

A technology of laminated panels and reinforced grids, which is applied in the direction of erecting/assembling bridges, bridge parts, bridges, etc., can solve the problems of inconvenient hoisting and poor bonding performance of the superimposed interface, and achieve convenient hoisting, enhanced bonding performance, The effect of high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

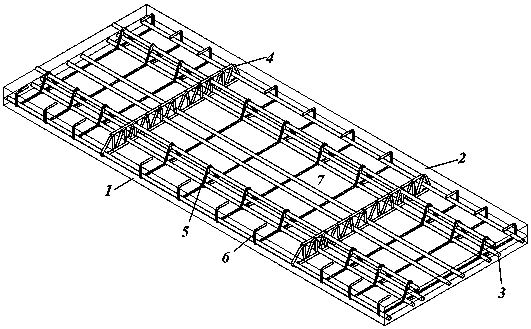

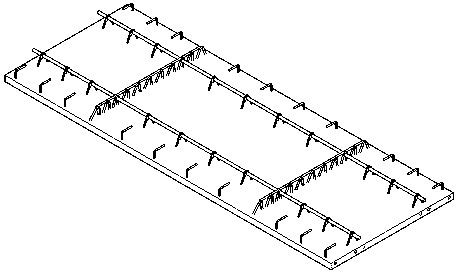

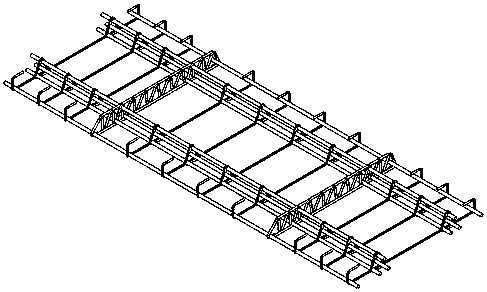

[0026] The invention discloses a UHPC and NC laminated panel structure and a construction method thereof in the form of a triangular space grid frame with reinforcement. The laminated panel component of the invention includes a prefabricated UHPC layer 1, a cast-in-place NC layer 2, and a triangular space steel mesh frame 7, the triangular space steel grid frame is arranged in the laminated slab, the thickness of the UHPC prefabricated layer is 1 / 3~1 / 4 of the total thickness of the laminated slab; the strength of the NC cast-in-place layer is C40~C60, The thickness is 2 / 3~3 / 4 of the total thickness of the laminated board. The bonding between the two superimposed layers is good, and the surfaces fit together perfectly to form a whole that works together.

[0027] Before pouring the NC layer, the triangular space steel grid frame 7 exposes the surface of the UHPC bottom layer 1, which is used to strengthen the rigidity of the prefabricated UHPC bottom layer 1 during hoisting. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com