Sludge treatment method

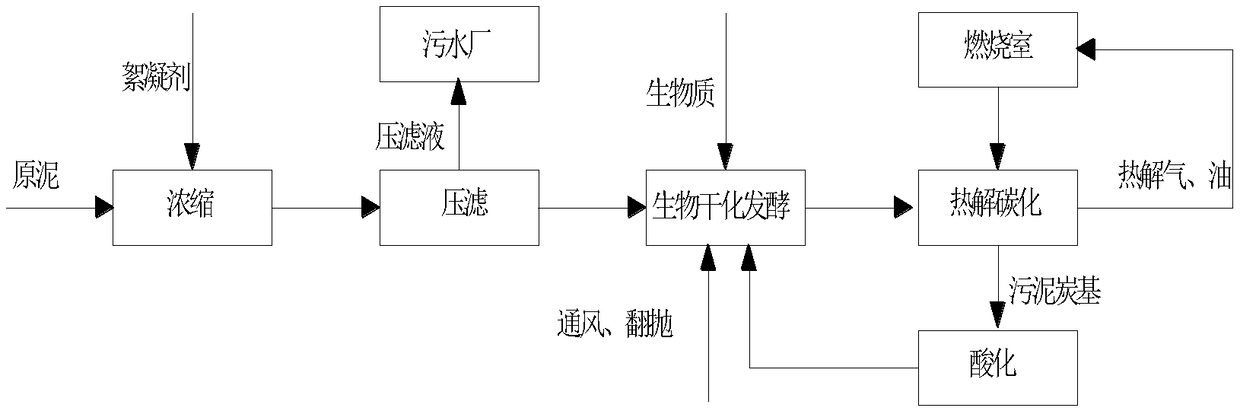

A technology for sludge and sewage plants, which is applied in biological sludge treatment, sludge treatment through temperature control, and pyrolysis treatment of sludge, etc. It can solve problems such as high energy consumption, high cost of sludge treatment and disposal, and complicated process routes. , to achieve the effects of reducing energy consumption, shortening the fermentation cycle, and maintaining a good living environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] S1: Add 1‰-3‰ PAM of the absolute dry weight of the sludge to the raw sludge with a water content of 99% from the sewage plant, and then concentrate it through a drum thickener. The water content of the concentrated sludge is 94.5%. Press filter with a filter press to obtain a filter cake and filtrate with a water content of 80%;

[0026] S2: Add biomass such as straw, peanut shells, rice husks and the like with a moisture content of 10% to the filter cake sludge with a moisture content of 80% obtained in step S1, and fully mix, and the mixing ratio of sludge and biomass is 3: 1. After mixing, the moisture content of the mixture is 62.5%, and the obtained filtrate is discharged to the sewage plant;

[0027] S3: Inoculate the composite microbial inoculum into the mixed material with a moisture content of 62.5% obtained in step S2, the microbial inoculum with a dry weight ratio of 5‰ of the microbial inoculum mixture, and the main bacterial species of the composite inocul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com