Multi-compartment box nailing machine and nailing method

A nailing machine and box technology, applied in the field of machinery, can solve the problems of time-consuming, labor-intensive, low efficiency, etc., and achieve the effect of easy operation of the equipment, fast nailing, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

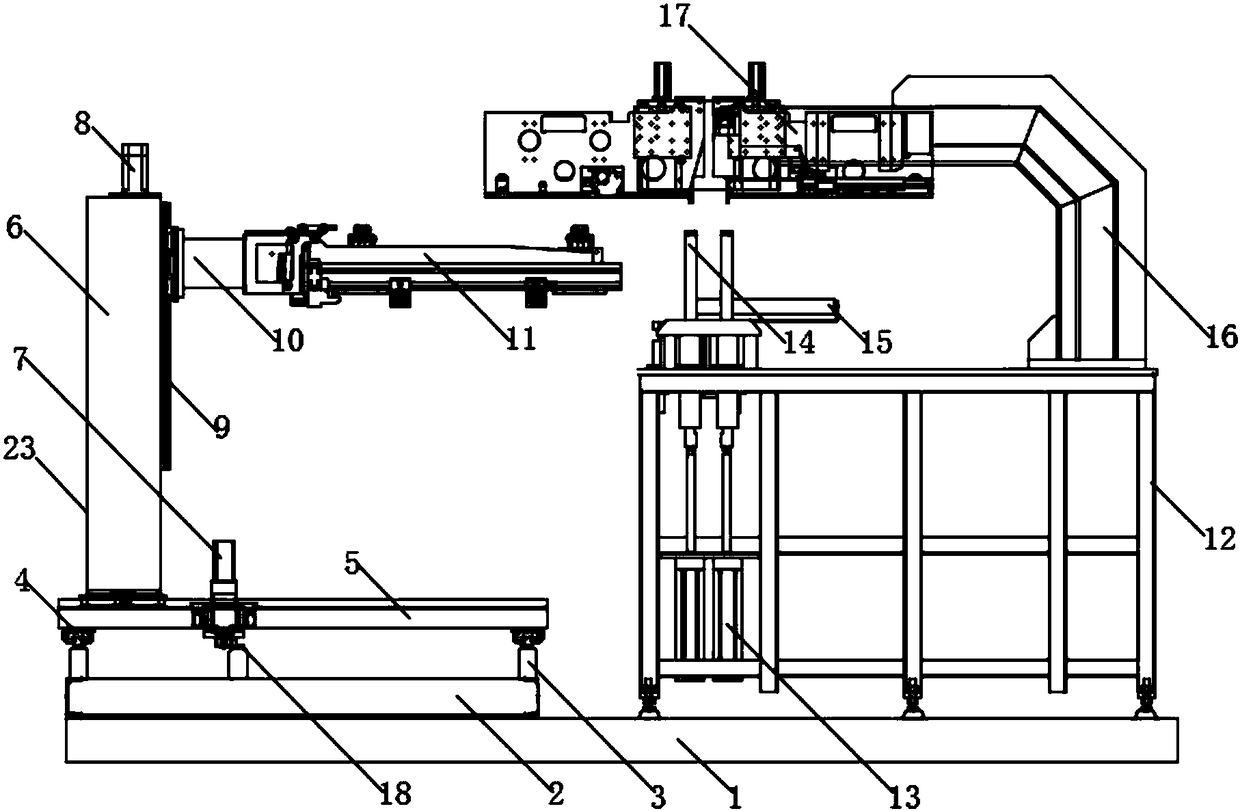

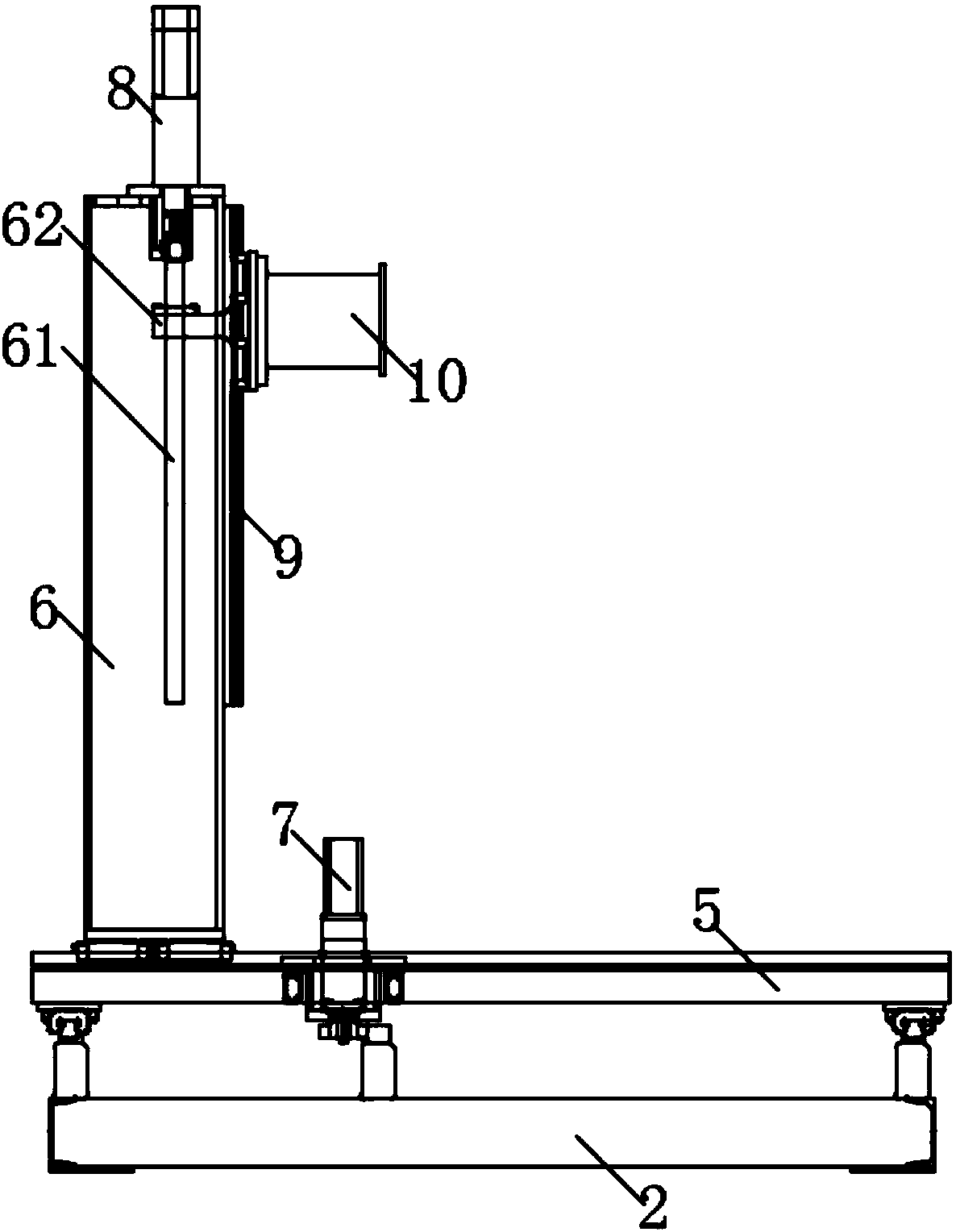

[0027] see Figure 1-4 , the present invention provides a technical solution: a multi-compartment box nailing machine, including a bottom plate 1, a first support plate 2 is provided on the left side of the upper end of the bottom plate 1, and the first support plate 2 is used to support the second support Plate 5, the upper end of the first support plate 2 is provided with a conveying unit 23, the upper end of the first support plate 2 is fixed on the left and right sides of the first sliding guide rail 3, and the upper end of the first sliding guide rail 3 is provided with a second A guide rail slider 4, the upper end of the first guide rail slider 4 is fixedly connected to the left and right sides of the lower end of the second support plate 5, a rack 18 is provided in the middle of the upper end of the first support plate 2, and the first The rack 18 is in mesh with the first gear, and the first gear is sleeved on the lower end shaft of the first motor 7, and the first mot...

Embodiment 2

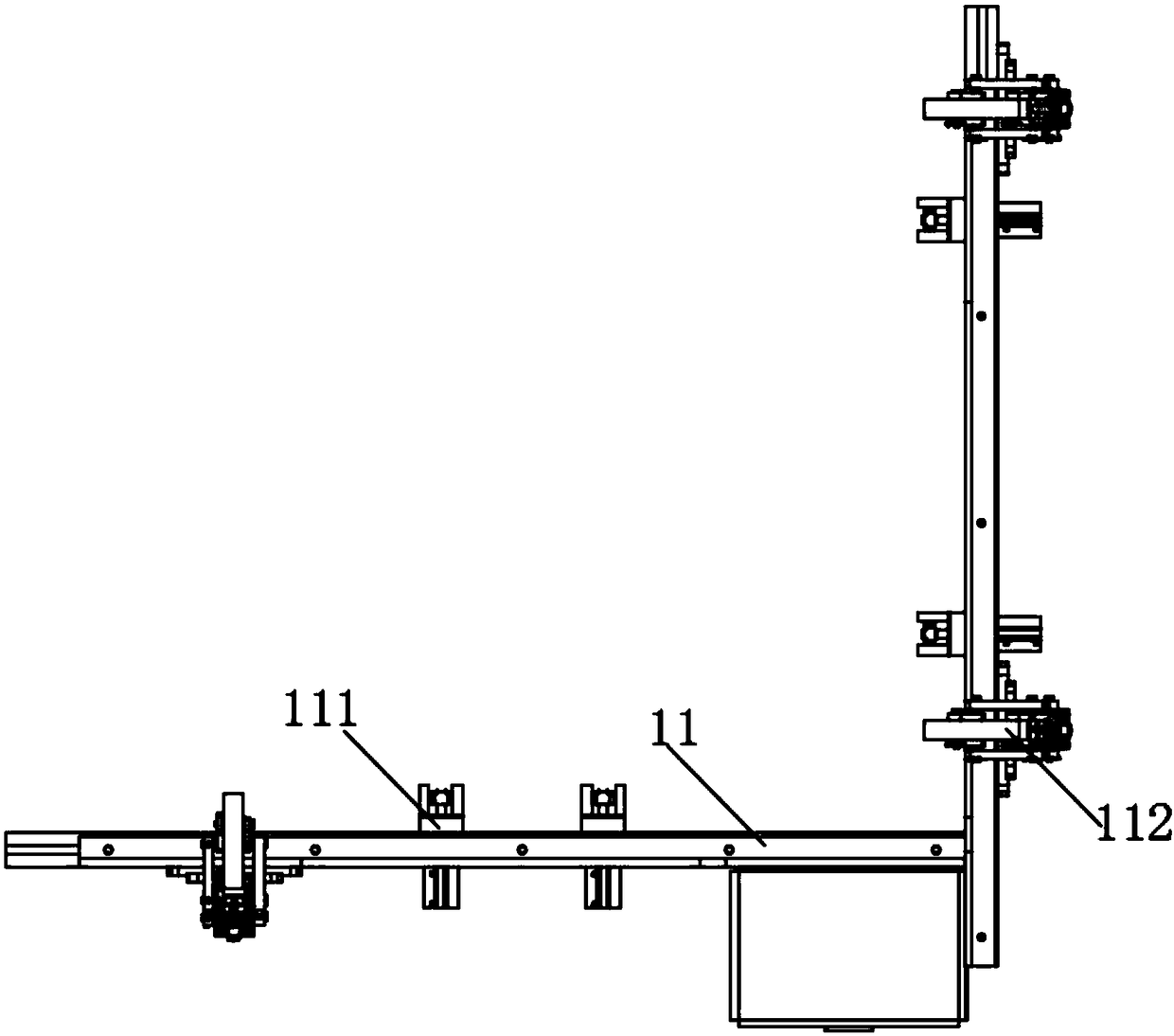

[0033] see image 3 and 5 The present invention provides a technical solution: the conveying unit 23 includes a third sliding track 19, a support plate 20, a fourth motor 21 and a manipulator 22, and the four corners of the upper end of the first supporting plate 2 are fixedly connected with the third sliding track 19, The upper end of the third sliding track 19 is connected with a support plate 20 through a pulley, the right end of the support plate 20 is fixedly connected with a fourth motor 21, and the lower end of the fourth motor 21 is connected to the third sliding track 19 through a transmission wheel. The upper end of the support plate 20 is fixedly connected with the manipulator 22 , and the right end of the manipulator 22 is fixedly connected with the clamping arm 11 .

[0034] A nailing method for a multi-compartment box nailing machine is characterized in that it comprises the following steps:

[0035] 1), place the material that needs to be nailed on the clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com