A test method for wall turbulence resistance of surface groove structure

A technology of turbulence resistance and testing method, which is applied in the detection field, can solve problems such as complex system, difficult clamping, and poor applicability, and achieve the effects of high energy consumption calculation accuracy, simple and reliable system, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

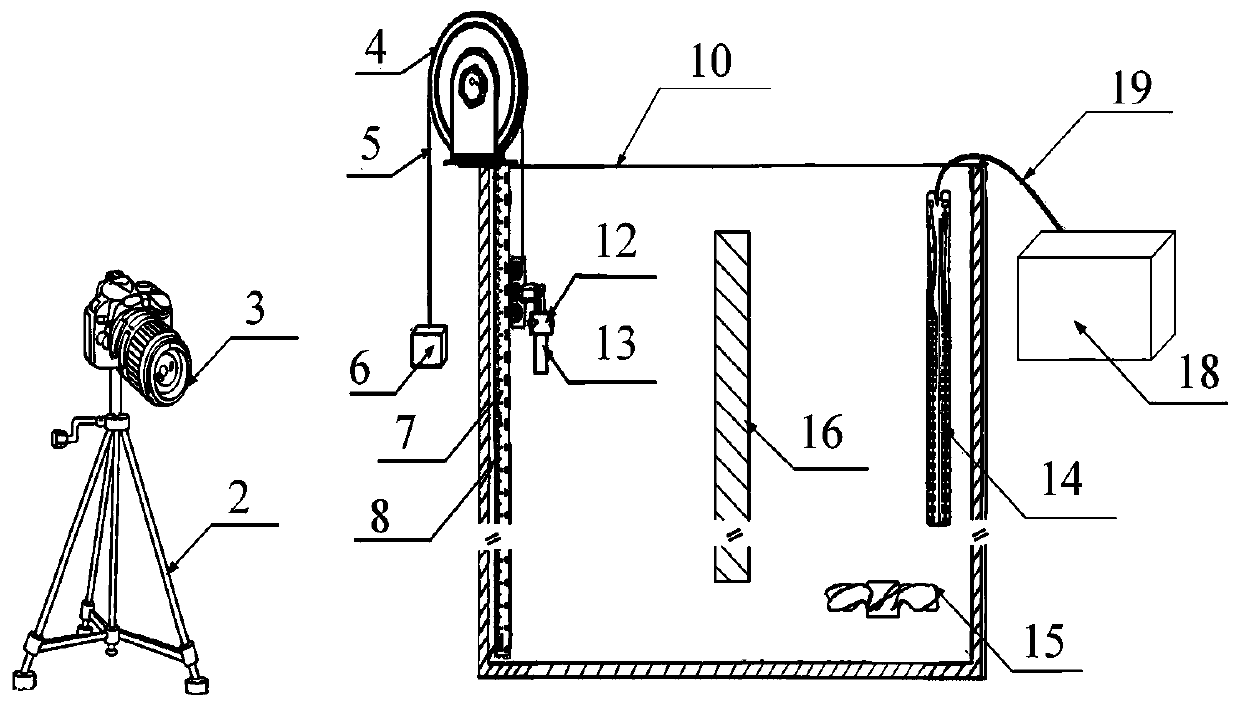

Method used

Image

Examples

Embodiment 1

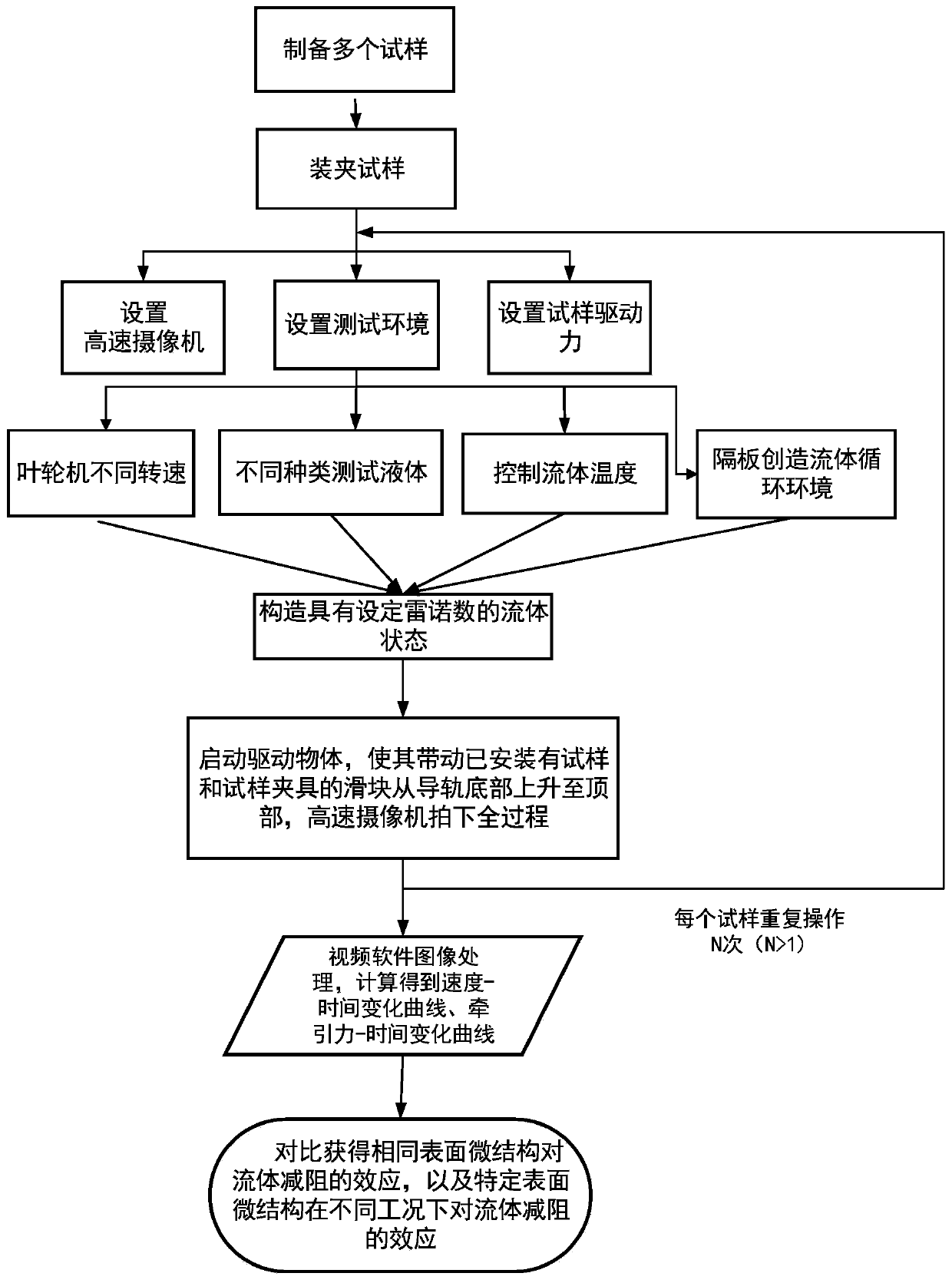

[0087] A method for testing wall turbulence resistance of a surface groove structure, specifically comprising the following steps:

[0088] (1) preparing a plurality of samples 13;

[0089] (1.1) The experimental equipment and processing parameters used are: ultraviolet laser with a wavelength of 355nm, a frequency of 55khz, a power of 1.6W, a scanning speed of 100mm / s, and scanning 10 times;

[0090] (1.2) Material and treatment process: 8 pieces of 304 stainless steel sheets with surface polishing were used in the experiment, with a specification of 4cm*4cm*1mm; one of them was a sample with no microstructure on the surface, which was used as the original control sample , and the remaining 7 single-sided laser etching prepared parallel groove patterns, and the scanning line spacing was 50, 80, 110, 140, 170, 200, 230 microns, and then the processed stainless steel surface was processed with a low surface energy reagent. Modification to obtain a micro-grooved surface with su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com