Manipulator for drill floor

A technology for manipulators and drill floors, which is applied to drill pipes, drill pipes, and drilling equipment. It can solve the problems of low efficiency of drill pipes entering rat holes, high personnel safety risks, and high labor intensity, so as to reduce operating personnel and control safety. Risk, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

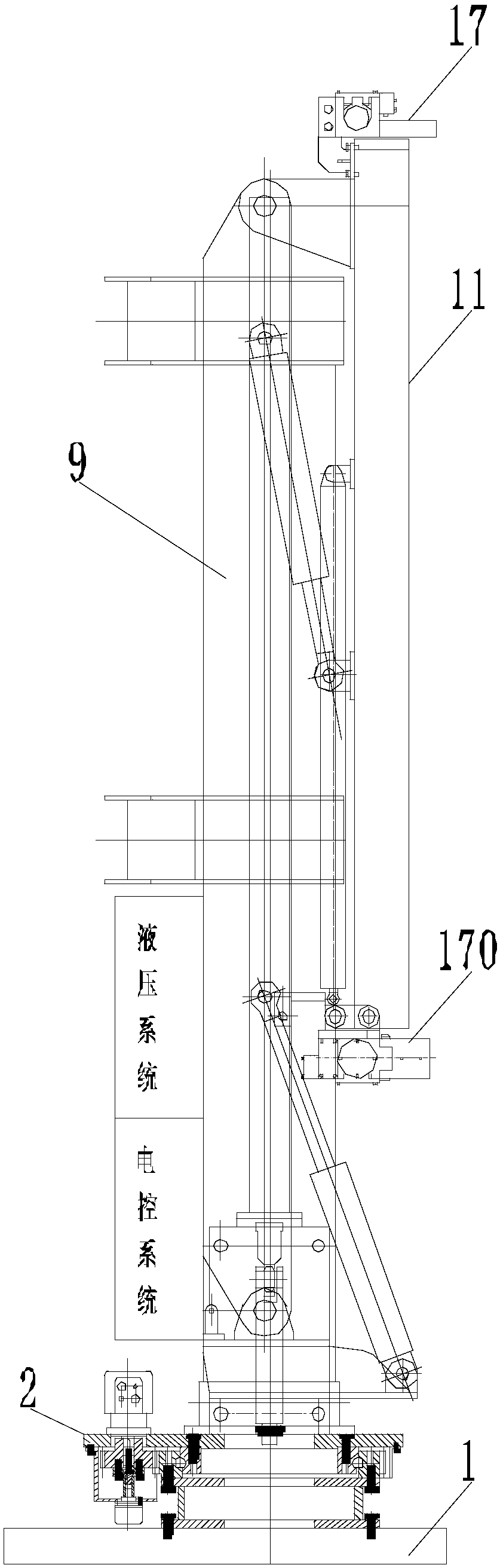

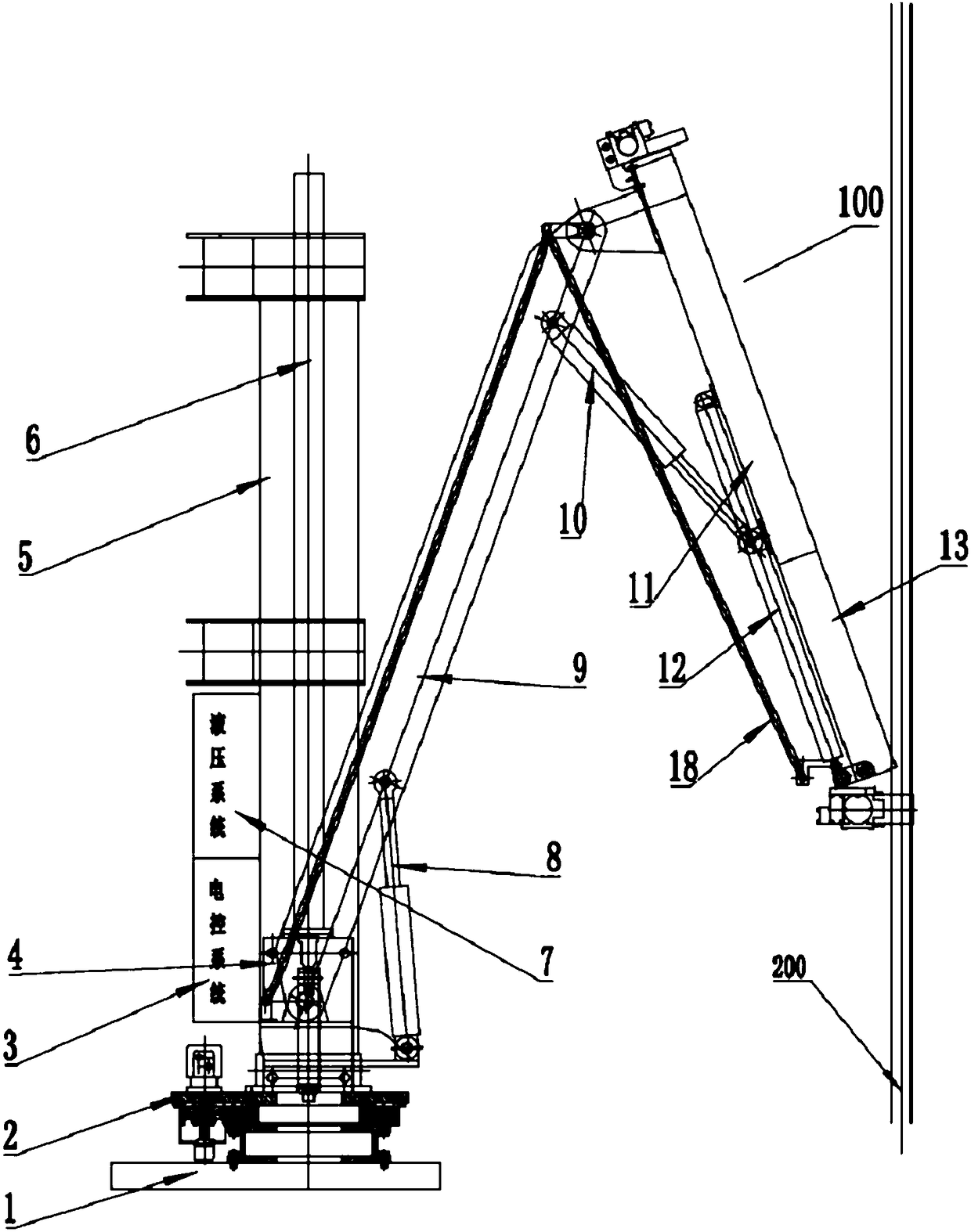

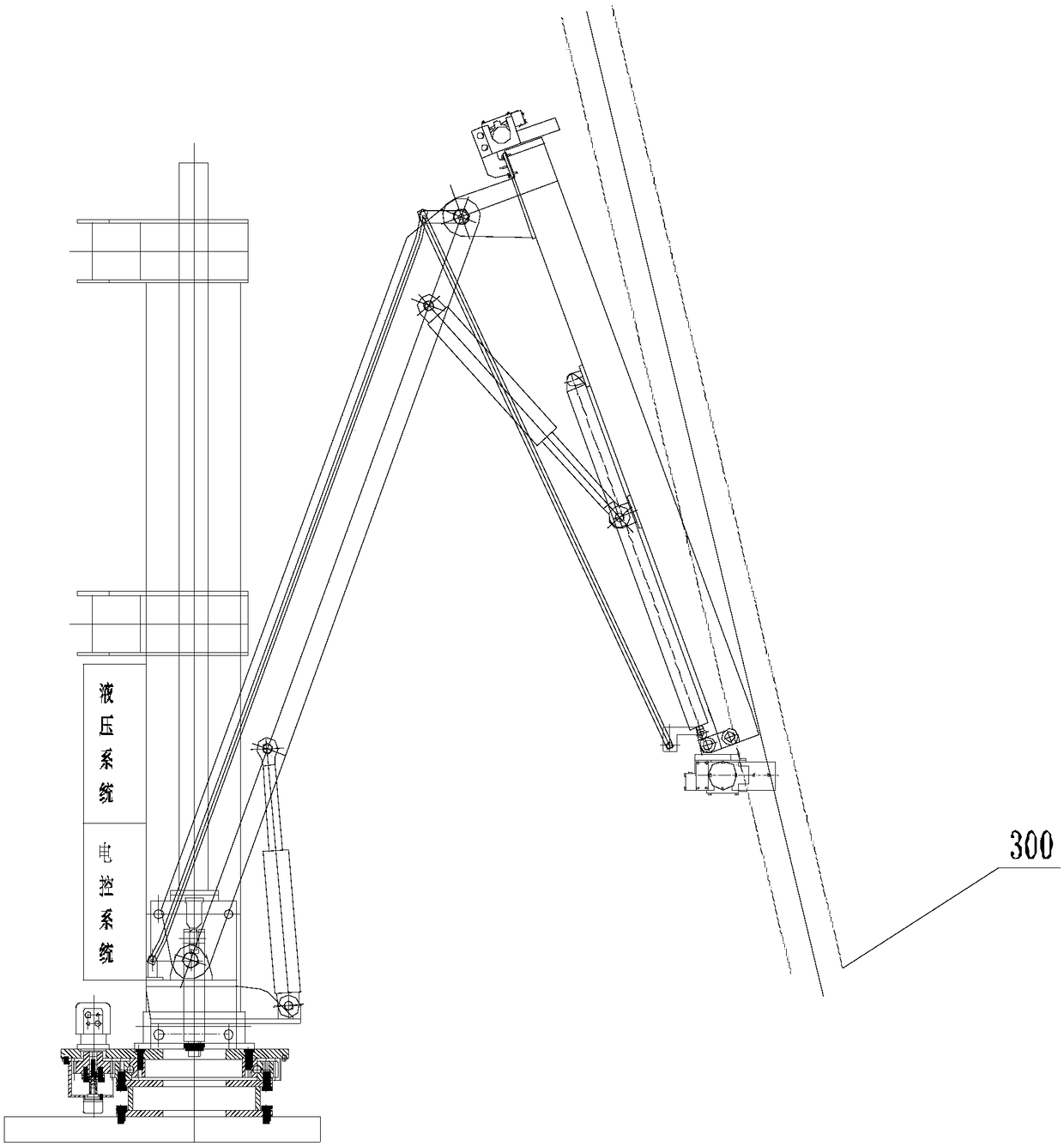

[0037] see Figure 1 to Figure 4 As shown, the present invention provides a drill floor manipulator, including a horizontal moving guide rail 1, a slewing support 2, a moving slider 4, a vertical moving guide rail 5, an inner moving arm 9, an outer moving arm 100 and a link mechanism 18.

[0038] The horizontal moving guide rail 1 is fixedly connected with the drill floor surface, the slewing bearing 2 is installed on the horizontal moving guide rail 1, and the vertical moving guide rail 5 arranged vertically is connected with the slewing bearing 2, which forms an integral column for the multifunctional manipulator; the vertical moving guide rail 5 can Rotate relative to the slewing bearing 2.

[0039] The moving slider 4 is installed in the vertical moving guide rail 5, the fixed end and the movable end of the first oil cylinder 6 are fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com