Safety chuck device allowing wound and unwound roll materials to be conveniently stored, clamped and taken out

A safety chuck, rewinding and unwinding technology, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of increased roll width swing, product quality decline, and uneven winding, etc., to achieve Circumferential beating is small, preventing product quality from deteriorating and avoiding uneven effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

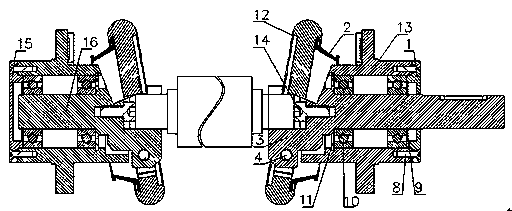

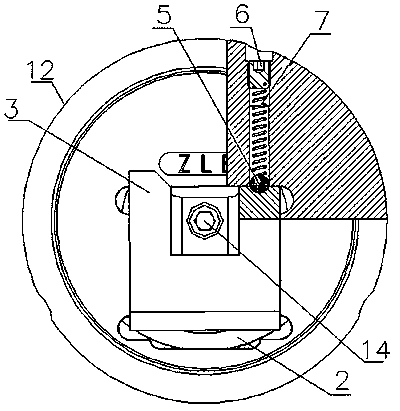

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

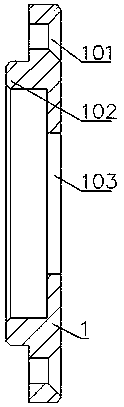

[0029] Such as Figure 1-9 As shown in , a safety chuck device that is convenient for rewinding and unwinding the roll material, placing the card, and taking it out includes a chuck at the active end, and the chuck at the active end includes a disk 12, and the groove 1202 at one end of the disk 12 is a Connect the rubber pad 2, the other end of the disc 12 is connected to the long shaft 3, the shaft 301 of the long shaft 3 runs through the disc 12 and the rubber pad 2, and the apex 306 of the groove block 305 of the long shaft 3 is clipped to the top of the disc 12 The top corner of the square hole 1203, the middle part of the shaft 301 of the long shaft 3 is connected to the flange seat 13 through the symmetrically fitted bearing 10, and the inclined end 1302 of the flange seat 13 protrudes into the rubber pad 2, the The ring groove 302 in the middle of the long axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com